It’s a subject that causes a sensation in cinemas and on the big screen: a murder occurs and the police lead an investigation to find the culprit. Thanks to the most modern technologies, criminals are usually apprehended quickly. Unfortunately, this is not just fiction. Nearly half a million people worldwide die each year as a result of intentional homicide.In 2023, the solved homicide rate in the United States is approximately 50%, but these rates vary by country. Taking France as an example, in 2022, 69% of homicides were solved. You should know that 3D technology plays an increasingly important role in investigative and forensic work, often contributing to its success. Today, very few homicides are not investigated using 3D reconstruction or 3D scanning technology.

3D forensics is an important part of modern forensics. It involves using 3D tools and human decision-making to reconstruct, analyze and treat criminal behavior. This autonomous domain is increasingly used in criminal law and to elucidate crimes. To better understand the role of 3D technology in investigative work and forensic evidence analysis, we spoke with several experts.

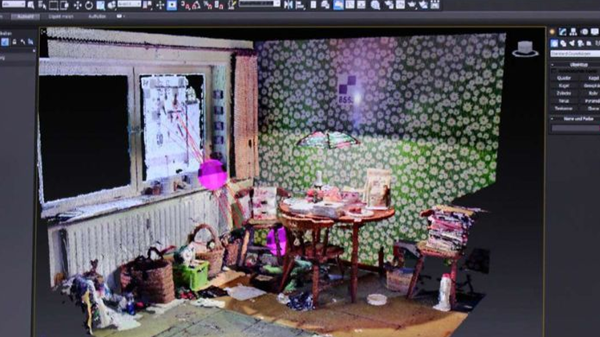

3D technology is increasingly used directly at crime scenes (Photo: APA/Georg Hochmuth)。

Application of 3D technology in forensic medicine

3D technology can collect and analyze not only digital media, but also physical evidence, including prints. Here we are talking about 3D scanning and additive manufacturing.

The role of the 3D scanner

photogrammetry systemUsed in investigations since the 1930s, short-range photogrammetry systems have been widely used in forensic medicine since the late 1990s. They open up new possibilities, particularly for measuring crime scenes and determining the size of criminals. Today, 3D laser scanning technology is used in almost every country. The Hamburg Cantonal Police (LKA) confirms: “3D scanners are frequently used in police work to evaluate or compare incident locations and/or physical objects, including in digital form.”

Crime scene archives use different scanners, including floor-standing scanners and mobile scanners. What is used here isArtec portable scanner. (Photo credit: Artec 3D)

Eugene Liscio, a 3D forensic analyst who has solved cases in Canada, the United States and Europe and who teaches at the University of Toronto, added: “The four main scanning technologies are photogrammetry, lasers digital scanning, structured light scanners and application-based scanners. of digitization.

Photogrammetry creates realistic texture networks and combines them with surface images,CT scans and MRI scans are combined to provide a detailed 3D view of the body. Thus, the wound can be enlarged, analyzed and compared to the criminal instrument or the direction of the shot. In 3D scanning, we distinguish between volume scanning and surface scanning. Volume scanning takes high-resolution images and requires special software and expertise to create 3D models from the data. Surface scanning is more user-friendly because only surface details are captured and integrated software is used. It is reliable for post-mortem injury analysis and field marking methods. The landmark method uses landmarks in images or data to create an accurate reference system for accurate measurements and comparisons. Additionally, photogrammetric data is collected using drones or DSLR cameras to create 3D models of crime scenes. The entire reconstruction process can be viewed using VR glasses or using virtual reality in a virtual reality space.

crime scene3D reconstruction. The location of the attack can be calculated from traces of blood. (Photo credit: Sofia Lavkansky)

North Rhineland– Area 54.2 of the Westphalian Criminal Court (LKA NRW), responsible for measuring, reconstructing and visualizing crime scenes, explains: “The use of 3D laser scanners allows crime scenes to be digitally preserved in three dimensions and to analyze them retrospectively. process of analyzing and reconstructing events, such as calculating volume, determining field of view and direction of fire, and determining the size of the offender.

to use3D scan for investigation

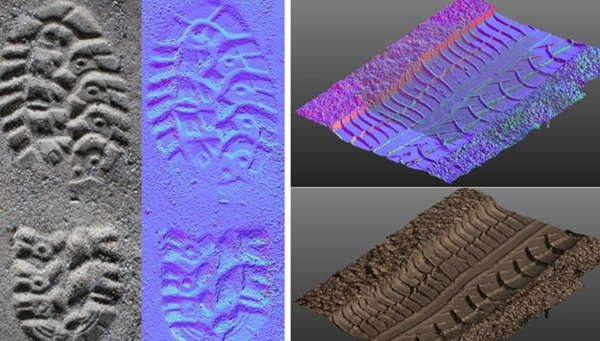

used by investigators3D scanner, place it on the footprint or tire tracks and start recording. At the same time, a camera connected to the scanner takes a photo. After a few seconds, users can see a preview on the built-in screen to check if the image is clear. A detailed analysis is then carried out in the laboratory, where traffic specialists examine the length or depth of the contour and compare the traces to other crime scenes.

Spurensicherung mittels tragbaren 3D scanning with a 3DF scanner. (Image source: Fraunhofer IOF)

The role of 3D printing

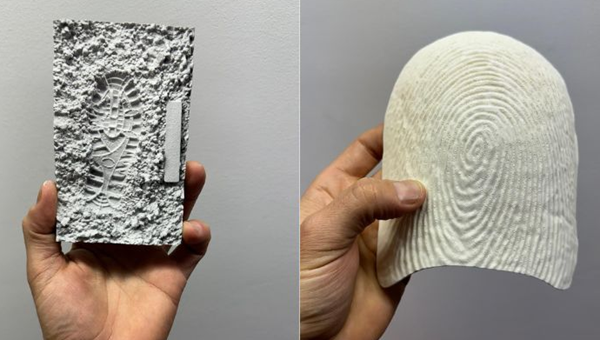

SinceSince the early 2010s, 3D printing has been used in the forensic field to reconstruct evidence, with the printing technology selected based on the intended use. Resin printers are ideal for detailed models, while powder bed fusion can be used for robust parts. However, FDM 3D printing is the most commonly used because it is affordable and versatile.

LKA North Rhine-Westphalia comments: “3D printing technology is used specifically as a technical tool to create so-called trackable objects, which serve as a digital backdrop for the movement of people or objects.” LKA Hamburg, which does not yet have a 3D printer, also explained that 3D printing could be considered for the physical examination of digital objects.

Murder of woman’s spine killed3D replica. Bone is difficult to produce with traditional manufacturing methods. Printing was carried out on a Creality CR10-V3 3D printer (Photo: Eugene Liscio).

The potential of 3D technology in forensic medicine

3D technology offers better analytical possibilities for forensic and investigative work, giving the opportunity to find and arrest the right criminal. The LKA of North Rhine-Westphalia confirms that 3D scanning technology has permanently changed investigative work throughout the country, especially at the Homicide Commission.

Joe, a renowned forensic artist at the National Center for Missing and Exploited ChildrenMullins also noted, “With current methods, we can scan a skull and print it on the spot. » Recently I had a skull scanned in Barbados, then 3D printed in Virginia and 3D printed in New York. This was not possible 20 years ago. “

Skull making. (Photo credit: Joe· Mullins)

Due to the development of technology and digital possibilities, including the use ofUsing VR glasses or VR cellar viewing technology, investigators can have three-dimensional access to reconstructed crime scenes. LKA NRW emphasizes that different perspectives can be considered here. They explain: “The observer thus no longer plays the role of an external observer, but can virtually enter the crime scene and immerse himself in a digital representation and reconstruction of the criminal process. The integration of the most various allows.” the file Being able to be viewed interactively, the knowledge thus acquired can have a decisive influence on the appreciation of the links between traces, testimonies and facts, which would not be possible if “we did not adopt this perspective”. point of view.

3D laser scanners allow investigators to view crime scenes on their computers and consult each other, even when they are away from their computers. “This opens up the possibility of having a realistic view of the crime scene, going to the crime scene and moving around without having to first visit the crime scene,” confirmed the criminal police. This allows investigators and court officials to simultaneously view a virtual crime scene and discuss it together. So even in the case of a gun crime or chaotic car accident, technology can provide a complete view of the incident and identify the angle of impact of the bullet.

crime sceneThe 3D reconstruction allows you to visit it even after its departure. (Photo credit: Jérémie Crowell)

Additionally, the technology ensures that evidence will not be damaged if it needs to be transported. This technique is useful for facial reconstruction, as traditional techniques require a layer of clay and plaster on the skull to reconstruct it. This process is repeated several times, causing damage to the skull.The 3D technology eliminates the need to touch the skull and creates a computer model in which software is used to mimic the reconstruction in clay, creating a virtual reconstruction from which a 3D printed replica can be produced. Even in forensics, shoe or tire marks are often cast in plaster, a time-consuming process that destroys the marks, but the use of 3D scanning can help overcome these challenges and preserve the marks.

For Mullins, the biggest advantage is that the originals have been preserved:“Whether it’s skulls or important pieces of evidence, there is no problem. In the field of forensic art, there have been cases where skulls have been lost. Put “I have a process in place to scan, print and photograph all skulls as a backup in case anything goes wrong with the originals.”

to useThe result of a 3D scan with a 3DF scanner. (Photo credit: Fraunhofer IOF)

at presentThe use of 3D technology in surveying work

3D technology has many applications in surveying work. Liscio explained that forensic work includes three main elements: documentation, analysis and visualization. In this case, 3D printing acts as a documentation product and visual aid.

3D printing is primarily used to reproduce evidence and help preserve real evidence. The victim’s finger can thus be reconstructed in 3D to unlock technical devices. In court, 3D printed replicas, such as skulls or weapons, help to clearly illustrate injuries and the sequence of events. “We generally don’t bring bones to trials, but we can present rebuttals,” Liccio noted. “For example, weapons can be printed to explain to the judge, jury and other investigators that this is the weapon used. Currently, 3D is used. The technology is used to show the crime and help people to understand it. discover in different ways. There is nothing wrong with seeing the image in a photo, but having something in your hand and being able to see it helps” Printing is also used as an educational tool. forensic medicine, offering anatomical displays for staff medical.

Enlarge shoe prints and fingerprints3D printed replica. (Photo credit: Eugène Lisio)

3D scanning technology also makes it possible to reconstruct an entire crime scene in order to understand its location and the objects found there, and to illustrate them visually. LKW NRW explains to us: “Recording a crime scene with a 3D laser scanner as part of crime scene documentation is a complementary and sometimes firmly integrated means of police work at crime scenes.” The LKA Criminal Science and Technology Department in Hamburg also uses 3D scanners to carry out measurements to digitally represent and reconstruct various incident locations.

3D technology is also gradually being used in the field of forensic archaeology. It offers huge potential in this area, because it allows us to represent what objects looked like before. For example, research is underway to use 3D printing to reconstruct burned bones.

The use of 3D technology in investigations has led to significant progress in many cases around the world. A famous example occurred in Ohio, USA, where the face of a discovered skull was reconstructed using the Clay Tools program and then 3D printed. This allows investigators to verify identities and move the case forward. Another incident involves the infamous suitcase murders of 2015, which saw the first combined use of 3D scanning and printing technology. West Midlands Police worked closely with the University of Warwick manufacturing team to use 3D technology to analyze the charred bone fragments and identify them as belonging to the suitcase examined. This plays a vital role in identifying victims.

in the event of fatal head traumaExample of a 3D printed skull part. (Photo credit: Errickson, D., Carew, RM, Collings, AJ et al.)

Legal situation: Court3D response

A study by the Cranfield Institute of Forensic Medicine found that court presentationsUnderstanding of the technical language used when printing 3D models increased to 94%, compared to just 79% for photographic images. However, the use of 3D technology to record crime scenes is not yet regulated by law. Lawyer Jens Ferner, an IT lawyer who deals with 3D copyright and developments around 3D technology, confirms: “There are no clear legal guidelines for public or private investigators, because the way whose documents are executed is regulated…at the procedural level. the subject is addressed at the level of the use and evaluation of evidence: documents of poor quality can lead to the negation of their probative value, or even their prohibition of use, in which case state investigators have established certain documentation standards, but the law does not provide for these standards. .”

Main challenges

One of the biggest challenges with 3D technology in surveying work is the time and cost factors. Liscio explains: “You need to choose the right tool for the job at hand. Sometimes that means investing in different tools or renting a scanner because you don’t have the right tool. Going from scanning to 3D printed model is not easy either. It’s a lot of work, and it’s often a challenge because we’re dealing with very complex and delicate parts that require a lot of help. “This means that investigators must become experts in the field and learn to use new work procedures and work tools.

shoe print3D scanning. (Photo credit: Artec)

LKA NRW confirms this: “Documenting a crime scene using a 3D laser scanner is a time-consuming method that requires close coordination with people working in parallel at the crime scene. Additionally, the use of this technology generates a large amount of data. This data can only be processed and viewed with efficient computers and software. » They also emphasize that the time required to process the assessment, reconstruct the crime scene and visualize the data is justified in relation to the benefits that the technology brings to the system. investigation. The professional division of LKA Hamburg considers the lack of homogeneity of data and printer formats available on the market as well as the need for large storage capacities as a challenge.

future development

withAs 3D technology develops and improves accuracy, it is expected to be increasingly used in surveys. Liscio noted that 3D printing is well known in the forensic field but not yet widespread, and that this could change as precision requirements increase. Mullins is also confident that 3D printing will be used more frequently in the future: “Technology is advancing so quickly that 3D printing will become the standard to support investigations. It will continue to contribute to the resolution of cases, but at a faster pace. “

3D investigation work 3D investigation work 3D investigation work 3D investigation work 3D investigation work 3D investigation work 3D investigation work

to useArtec Eva for 3D scanning. (Photo credit: Artec 3D)

Despite the possibilities and progress made, it is important toMuch remains to be done to harness the full potential of 3D technology in survey work. An important step here is to train investigators through a training program. Additionally, continued research is needed to adapt technology to the demands of investigative work and to facilitate collaboration between technicians, attorneys, and investigators. In the future and in the long term, 3D technology has the potential to facilitate investigative work, bring criminals to justice and solve crimes more accurately. But to achieve this, we must continue to lay the foundations through training and research.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.