medicineAdvancements in 3D printing technology are booming. Today we highlight an innovation: researchers at the University of Texas at Dallas have succeeded in designing a 3D printed femur model. The project could give doctors a new tool to better prepare for bone reconstruction surgery and develop treatments for bone tumors. The model was developed in collaboration with orthopedic surgeons at UT Southwestern Medical Center, and preliminary results of the study were published in the Journal of Orthopedic Research.

This kind ofHow can 3D printed femurs facilitate bone reconstruction surgery? The study focused on the central part of the bone, defining precise parameters to generate a 3D femur model suitable for biomechanical testing. Although promising, this technology still requires several stages of research before it can be used in the clinic.

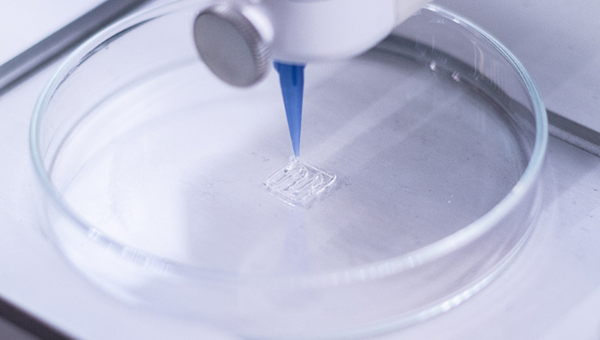

to useFemur sample made by 3D printer.

exploreNew method for research in the biomechanics of 3D printing

To examine and evaluate new surgical methods and implants, surgeons conduct biomechanical studies using donor bone or commercially available synthetic bone. This approach allowed them to determine the best fixation method and predict how the bone would react. However, traditional methods can be expensive and time-consuming. Furthermore, these solutions cannot be adapted to the specific needs of each patient, thus limiting their effectiveness in certain clinical situations.

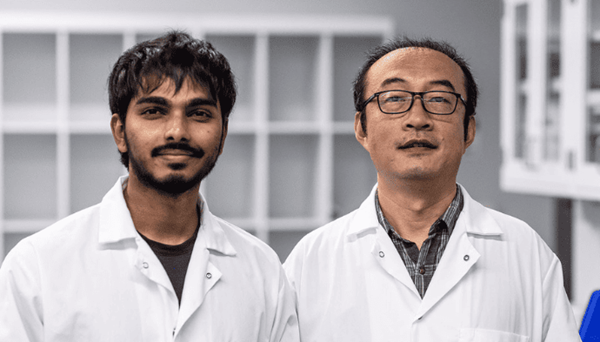

To meet this need,UT Southwestern researchers contacted UT Dallas 3D printing expert Wei Li, Ph.D., to develop a faster, more cost-effective biomechanical research solution. “To prepare for surgery, surgeons need to understand the shape of the bone,” said Dr. Wei Li. “Using 3D printing, we can create a model of the femur that accurately replicates its geometry in the body.” Ph.D., Mechanical Engineering, University of Texas at Dallas Kishore Mysore Nagaraja improved several versions of the femur through trial and error. In the manufacturing laboratory led by Dr. Li Wei, he performed different tests on each bone model to evaluate its mechanical properties. The goal is to bring them as close as possible to the natural femur.

Doctoral candidate in mechanical engineeringKishore Mysore Nagaraja (left) and Dr Li Wei (right)

Researchers created bone replicas using polylactic acid, an affordable and environmentally friendly polymer commonly used inField of 3D printing. The model represents the central part of the femur, measuring approximately 20 cm long and 2.5 cm in diameter. The biomechanical tests carried out showed that the performance of the replica was comparable to that of a human femur. Additionally, the cost of producing a 3D printed femur is estimated to be around $7.

Dr. Li Wei emphasized:3D printed bones have broad application prospects. For example, the polymers used could replace traditional materials such as titanium in bone repair surgeries. He also mentioned the possibility of printing tumors on these bone models to evaluate treatments, or the possibility of using these replicas to promote the regeneration of bone tissue in humans.ability.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.