The applications of 3D printing are very wide: from the food industry to the automobile, it makes it possible to create objects of different shapes and materials. The film industry has also benefited from advances in this technology. In recent years, advances in 3D printing technology have allowed filmmakers to design props, costumes and sets with unprecedented precision and speed. Top winners include “Avatar: Waterpath,” “Iron Man,” “Pinocchio,” “The Inventor,” “Thor,” “Star Wars: The Rise of Skywalker” and “Black Panther: Wakanda Forever.” The works make extensive use of these techniques. These innovations provide unparalleled creative freedom and flexibility not possible with traditional manufacturing methods. We spoke with film professionals, designers and printer manufacturers to learn about the latest advancements and uses of 3D printing in the film industry.

The world of cinema is constantly evolving technologically

Films often seek to provide extremely realistic costumes and props that immerse the audience in the action and make them complicit in the story. To achieve this, the film industry continues to evolve, using the latest technologies to push the boundaries of what is possible. This quest for realism and innovation dates back to The 18th century, a time when the first animated image sequences appeared. A major turning point was marked in 1895 by the Lumière brothers, who invented technology allowing black and white films to be projected silently from a single device. Thirty-two years later, the advent of talking cinema ushered in a new era, closely followed by color cinema. Today, in addition to advances in special effects, films are also adopting innovative 3D printing technology, which is revolutionizing the creation of sets, costumes and props.

picture1: The world of cinema is constantly evolving.

Frank Ippolito, founder of Thingergy Inc., one of Hollywood’s leading manufacturers of costumes, props and special effects makeup, confirms that over the past five years, almost every production has used 3D printers, both on set and sometimes even in props. the clothing department. Jason Lopes, Technical Director of Gentle Giant Studios, emphasizes that the most significant advancement in recent years has been in the materials available: “Today we have a much wider choice of materials, which allows us to create soft and flexible objects. for animatronics, ceramic for high-definition tools, and even nylon for characters suitable for movie sets and theme park needs”

Carlos, props designer, who contributed to the film “The Inventor”· Carlos Padilla highlighted that 3D printing has now become an important tool in cinema. “In recent years, manufacturers have made printers more accessible, allowing many small studios to integrate this technology into their workflows,” he explains. “Print quality has also improved significantly, with results available in just a few hours, whereas previously it took several days and required several people. Running the machine in the background is a real advantage: it saves time and materials. while ensuring precise production. This gives us time to focus more on creativity and reduces the risk of errors during prototyping and testing”

What are the advantages of 3D printing in the field of cinema?

Audience expectations from films are increasingly high, requiring filmmakers to pay attention to every detail, whether it is content or visual aesthetics. Thus, each element, whether it is an accessory or a piece of clothing, becomes important.Julia Koerner, known for her 3D printed fashion lines and costume design for the film Black Panther, explains the difference between fashion and 3D clothing: “In fashion, the main focus is on fit and the look. in the clothing aspect, we must also take into consideration the story, the actors, the sets, post-production, etc..”

Producing extremely precise parts down to the smallest detail can take days, weeks, or even months of work. Traditional manufacturing techniques often involve intensive manual labor, which poses a significant challenge when designing costumes for a large number of characters, such as in an entire military scene.3D printing constitutes a valuable asset here, allowing models to be reproduced quickly and faithfully. Designers can create a unique model and reproduce it in just a few hours.

With over ten years of experienceGilles-Alexandre, 3D designer, creator of the short film “Chase Me”, and filmmaker Deschaud affirms the contribution of this technology: “3D printing allows two fundamental things: a significant saving of time in the manufacture of components, an economy money and increased quality. The precision and detail of 3D printed models is impressive and can be easily iterated to improve or repair parts. » As 3D printing relies on digital models, these are easily editable and can be continuously adjusted, which would be time-consuming and expensive with hand-made accessories. Lopes also highlighted the speed of the technology: “For us, the biggest advantages are speed and reliability. To me, we have reached a point where this technology is not only accepted, but has become the norm. Technological and material advancements have proven invaluable in our production processes. »

picture2: Gilles-Alexandre Deschaud used 3D printing to create more than 2,500 statues in the film Chase Me.

at the cinema3D printing offers the possibility of creating prototypes or printing several variants for comparison purposes, ensuring great flexibility. If a part is damaged during shooting, it can be quickly reprinted. Additionally, through simple digital adjustments, the right production can be designed without having to wait for the final selection of actors. 3D printers are relatively easy to transport and also allow for on-site production, avoiding delays caused by shipping necessary components.

In addition to the time and money savings mentioned previously,3D printing also offers design freedom. It allows parts to be produced that are impossible with other manufacturing methods. Much of this design freedom comes from the variety of materials available for 3D printing. As well as being aesthetically pleasing, this also has practical benefits on set: by using lightweight materials and incorporating white space, lighter clothing and accessories can be designed while still maintaining a grandiose ‘on-screen’ look. » on the set.

carlos·Padilla(Carlos) Padilla explains: “It is a valuable tool that allows great freedom of experimentation, especially with shapes or structures that would otherwise be difficult to achieve. Additionally, it can run 24 hours a day to accomplish multiple tasks since we primarily work with digital. files, this allows parts of the team to be decentralized and only send files to print rather than physical items so that other technicians, artists, etc. can collaborate remotely on the same project, which facilitates communication between the different local services to validate, authorize and. review projects »

picture3: This helmet was designed by Julia Koerner and would not have been possible without 3D printing.

From model to finished accessory/clothes

for the world of cinema3D software

AndAs in many other areas of 3D printing, before the printing process can begin, a model must be developed from scratch or from a 3D scan. Jason Lopes, who worked at Legacy Effects for many years using software such as Autodesk Maya, Inventor, Fusion 360, Modo and SolidWorks, demonstrated the different tools available for design. In the film “The Inventor”, Carlos Padilla chose to use 3D software from Dassault Systèmes to recreate the model and machine of the Inventor. However, he also uses Blender, especially because of its “huge ecosystem of add-ons that cover almost any task.” “It’s a great way to combine mechanical structures with more ‘organic’ pieces like sculptures,” he explains. » However, he sometimes uses SolidWorks or FreeCAD for certain specific tasks, alternating between PrusaSlicer and SuperSlicer.

Julia Koerner also highlighted the diversity of software available, noting that there is a wide range of programs often used in the construction field. For more complex designs, it uses its own algorithm.

Jason Lopes explains that he uses all the tools available, but his default workflow mainly consists of Maxon ZBrush, Maya, Adobe Substance and Materialize Magics.

Using these software can also promote smoother collaboration.Victor Marin explains it this way: “Nowadays, it is easier for directors to illustrate concepts and sometimes sketch designs using 3D printed concept art. This not only helps the director, but also the camera operator to visually understand how light interacts with the room. In It is better to invest time and money during pre-production than to waste time and money after production begins »

The role of 3D scanning in film production

“Scanning plays a key role when designing costumes or props for actors. The body or head is scanned and this data is used to design around the actor’s actual proportions. You can then use this data to 3D print at low resolution or machine them foam to check the fit of the printed components so that they can be manufactured more quickly for the actors before the final adjustment is made in person, ”says Jason Lopes est. best known for using printing 3D to design and manufacture the famous Iron Man suit.

3D scanning shows how detailed and personalized 3D printing can be used. 3D scanners can provide more accurate results than taking manual measurements. Frank Ippolito confirms the use of 3D scanners in his studio: “We have several devices for data collection, such as manual 3D scanners such as the Artec Eva and the Artec Spider. » He also uses photogrammetry to carry out this process.

Which printing technology is best for film production?

What kindIt’s not always obvious which 3D printers are best for film production and for which projects each model is used. As James Reeves, managing director of voxeljet UK, points out, the film industry is “a very secretive industry”. The budget plays a determining role in these choices. For example, Gilles-Alexandre Deschaud initially considered an FDM printer for cost reasons, but ultimately opted for the Form 1 thanks to crowdfunding from Formlabs. According to him, this printer uses SLA technology to provide better quality even for small parts. At the time, printing could only be done with gray, transparent or black materials, but since then many resins are now available in a variety of colors.

Today, liquid resins are used3D technology is appearing more and more on film sets. The pieces created are generally smaller, ideal for making costumes, quick to make and very realistic. Carlos Padilla confirms this trend: “Depending on the studios, the parts are generally made with resin 3D printers, or in large studios like Laika, with high quality printers. » Used in the film “The Inventor”. Two 3D printing technologies are used. Carlos Padilla explained that metal 3D printing was chosen for some of the main characters’ feet, while an FDM printer and ABS filament were used for the lions because the material was strong enough to withstand long hours of filming.

Apart fromIn addition to Formlabs, the manufacturer Stratasys is increasingly cited in the field of 3D film printing. For example, in the Golden Globe-nominated animated film “Mr. Wired”, the Stratasys J750 using PolyJet technology was used to achieve wide color gamut printing. Designer Julia Koerner uses the latest version of this printer, the J750 TM, which she uses to print directly onto the fabric, rather than assembling 3D printed parts with the fabric. “This opens up new design possibilities in terms of portability, functionality and color aesthetics,” explains Julia Koerner.

picture4: Textiles can now be printed. (Photo credit: Julia Koerner)

Frank Ippolito explained that in addition to 3D printers, his company also uses CNC machines. It currently has around thirty 3D printers under the Markforged, Prusa, Raise3D, 3DP, Peopoly and Phrozen brands. He justifies this choice by specifically stating: “In the rapidly changing television and film industry, we need effective solutions. Most printing service providers are too expensive or too slow to meet our needs. So we want to do it in-house as much as possible. » Jason Lopes explains the technologies he uses: “Our innovation lab is equipped with wide format SLA, DLP (Nexa XiP and XiP Pro), Mimaki color printing, MJP, Desktop SLA and MJP and FFF.”

Post-processing

In the film industry,Post-processing of 3D printed models and props is very important to ensure the final visual quality of the film. As Victor Marin explains: “It is necessary to prepare the mesh before sending it for printing, and depending on the technology used (FDM, resin, etc.) it may be necessary to rework the part. Sometimes this involves sanding or shaping in a traditional way certain parts. Although 3D printer manufacturers strive to improve their machines every year to produce higher quality prints, they still often require cleaning and reprocessing. Lopes even noted that post-processing takes up to 99% of manufacturing time. This process includes removing support structures, cleaning models, and smoothing surfaces. Additionally, some parts may need to be manually painted to add additional detail.

The challenges faced by 3D printing in the field of film

The above-mentioned post-processing time is given to the film industry3D printing presents significant challenges. Apart from the time required, which is a key factor in film production, this process also incurs high labor costs. Creating many costumes and props requires a lot of manual labor. Gilles-Alexandre Deschaud devoted an additional 20 minutes to each of his Chase Me short films, totaling more than 800 hours. Julia Koerner also highlights these difficulties: “The challenge is that design and collaboration often take a long time. Some partners contact me at the last minute and underestimate the budget needed for design development.”

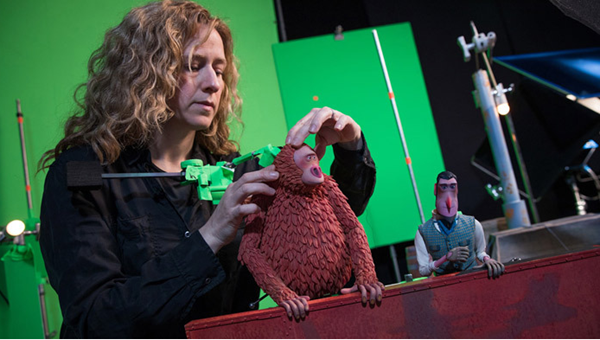

picture5: “Mr. Link” is one of the first films to use 3D printing (Photo source: LAIKA)

In addition, accessories should not only be beautiful but also durable.Frank Ippolito points out that “some older 3D printing technologies produce parts that are not strong enough for stunts and would be damaged if an actor dropped them. This is why he favors the use of materials based on nylon reinforced with carbon fiber.” He also mentioned that some advanced technologies can be very useful but are often difficult to obtain due to their cost. Frank Ippolito explains that the main obstacles were time and budget: the solution had to be fast and accommodate increasingly tight production budgets.

ForFor Jason Lopes, the main challenges remain cost and time: “The price of materials is often a barrier to innovation, particularly in complex designs that require numerous iterations before finalization. » He also mentioned another major obstacle, time: “When a printer breaks down. , it is important that a technician can repair it on site because we cannot always solve the problem ourselves. Additionally, much of our data cannot be sent. It is therefore essential to optimize availability to meet tight production deadlines. »

film industryAnother major challenge of 3D printing is understanding and adopting the technology. Jason Lopes explains: “Most entertainment companies don’t use software specifically designed for 3D printing. This makes it difficult to understand digital assets for digital displays or media and adapt them to additive manufacturing. The process can be complex, but ultimately, there is no best. way to ensure the best workflow from concept to reality »

futureWill 3D printing replace the traditional production process in the world of cinema?

3D printing has already played a key role in many innovative and award-winning film projects and will likely continue to be an asset in future productions. However, the studio and printer were unable to provide specific information on future projects. There are questions about whether 3D printing is not only a tool for manufacturing clothing and accessories, but could replace other traditional processes due to its flexibility and freedom of design. Certainly, the world of cinema, often shaped by technological advances, has also benefited from these innovations.

Gilles-Alexandre Deschaud firmly believes that the future of 3D printing in the field of cinema is assured: “3D printing is already omnipresent in the film industry. It is widely used for props and sets, both in stop-motion animated films and in American blockbusters. Creation. But it does more than that: it also intervenes from the design stage to validate prototypes or personalized concepts. It is clear that 3D printing is now an integral part of future films.

Victor Marin believes that 3D technology will play an increasingly important role in the future, as digital model creation and 3D scanning make work much faster than manual methods. However, he advocates an approach that combines the two processes and cautions against abandoning traditional techniques altogether: “If you need to create a statue, for example, it may be easier to resize it, adjust the proportions, or even do it in just a few clicks. Using a 3D scanner is also very beneficial as it can generate extremely accurate models from the scan, but it is important not to neglect traditional methods.

JulieJulia Koerner also advocates merging the two approaches. She sees 3D printing as a complementary design tool that offers the ability to create complex structures that are either infeasible with traditional manufacturing methods or simply didn’t exist before. In her designs, she strives to combine tradition and innovation, incorporating both techniques into her fashion designs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.