Introduction: As the US government releases information on unidentified aerial phenomena (BANG) report,“Hypersonic “The word has regained people’s attention, and the speed is generally positioned to exceed5Mach and more. Whether you believe in aliens or not, the space competition between the great powers has begun, and they are all pre-researching and developing an aircraft with unprecedented speed and flexibility.

△A conceptual diagram of a future hypersonic aircraft designed by an artist. At the same time, with3DPropulsion systems for printed parts are being developed to propel vehicles to hypersonic speeds

Specifically,“Supersonic “referred to in1Planes that have broken the sound barrier at Mach 1 (like the now retired “Concord “No. and to come “roar“Number).5Mach is five times the speed of sound, exceeding3500mile/Hour. But when the upper limit of this speed is reached, it enters the hypersonic environment.

Purdue University researchers explore a completely new metal3Dprinting technology through which they are able to produce fully dense final parts that are stronger than traditional molding methods. These parts can meet the application conditions in harsh hypersonic environments.

Explore the world of hypersonic technology

Carson, associate professor at Purdue University–Slab (Carson Slabaugh)explain:“5Mach is a difficult technical red line to cross.“since he2015Since the laboratory’s inception at Purdue University in20The team worked on high-speed combustion systems.“When an aircraft flies at high speed, the air flowing around and within the fuselage experiences extreme compression and heating. reached at high speed5At Mach, the temperature increases by approximately6times, the pressure increases hundreds of times. At the same time, this thermal and mechanical loading leads to a complete change in the aerodynamic, thermodynamic and mechanical regime of the structures.“

exist5When flying at speeds above Mach, the air temperature in the atmosphere during passage is several thousand degrees and the pressure is several hundred pounds. If you fly fast enough, the air itself can even become chemically reactive. Extreme flow conditions pose an engineering challenge for any aircraft system whose thrust comes from burning fuel.

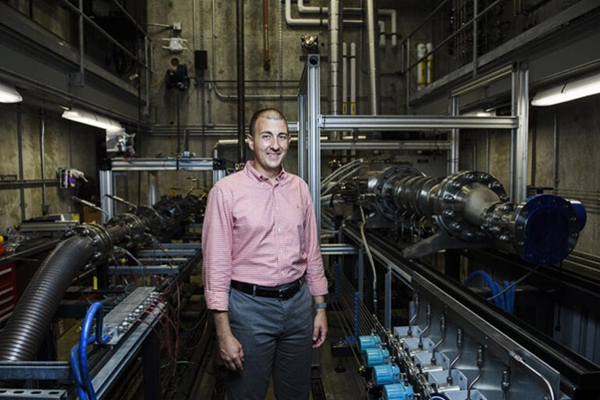

△Carson SlabaughAssociate Professor at Purdue UniversityZucrowIn front of the laboratory combustion test bench

Metal3DPrint parts

To meet this challenge,Slaband his team withVELO3DCollaborate to print fuel injectors with complex geometries to achieve extremely high fuel-air mixing performance. It would be impossible to produce such parts with traditional manufacturing methods, especially under extreme testing conditions that require high-strength superalloys.

Slabexplain:“Through our cooperation we helpBike3DThe company designed the high-speed combustion system and, at the same time, taught us how to better use3DPrinting technology. This is the kind of mutually beneficial relationship we build with industry partners as we solve the challenges associated with cutting-edge technology transformation.“

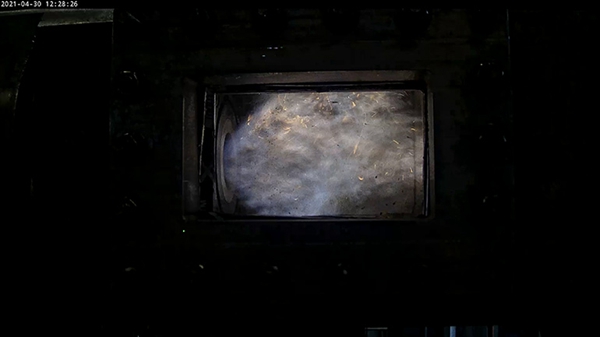

△The flame in the test room can simulate the high-speed propulsion system in a hypersonic environment

Much of the research and development of the hypersonic vehicles they are developing is supported by NASA and defense budgets.

The research and development costs associated with such advanced flight testing are also high, so the team hopes to reduce costs as much as possible, much like the Purdue University facility.SlabThe team is building a ground test site to verify aircraft engine components.

Slabexplain:“The components we designed will simulate operation in a hypersonic environment, while not needing to be airborne or moved and will remain bolted to the ground at all times.

Computational fluid dynamics (CFDs) and fluid-structure interaction (ISP) and other methods can be used to simulate the behavior of materials and structures in air or liquid flow. This allows engineers to optimize designs before anything is built.

Troubleshoot technical issues

Slabexplain:“A fundamental problem is that we cannot reliably predict flow and flame conditions in engines at hypersonic speeds.

He also explained how the team solved the problem:“us andBike3Dcollaborated to create a very large3DPrint the burner, which will be used to create a hypersonic environment in a ground test cell.“

To create a hypersonic ground vehicle, you need to build a rocket engine with a large converging-diverging nozzle and a plume of extremely hot gases traveling at supersonic speeds. All tested components are then placed in this plume.

Slabexplain.“passBike3Dwe design the injectors of this burner to create a very specific turbulent flow field that mixes the fuel at a certain speed and helps stabilize a very powerful flame in a very compact volume. This paves the way for everything we want to test downstream.“

△3DPrinting jet produces stable and powerful turbulent flames

To check this3DProperties of print burner using Hastelloy alloysXMade from a high-strength, high-temperature superalloy capable of withstanding hypersonic environments, the Purdue team was able to quickly determine which design would be most effective.

Engineers cleverly modified the injector flow path with five different designs. For3DFor printing, it’s just an adjustmentSTAGEData file problem. at the same time,VELO3D SapphireThe system’s print preparation software has an automatic adaptation function. Therefore, after the design is printed, it has passed the test of hypersonic test conditions.

In just two weeks, the team was able to pre-select the best performing product, presenting all the static and dynamic characteristics sought. This high-performance fuel injector meets the key parameters of burner performance, flame power and flame stability that engineers value most.

The team’s next step is to assemble a large array of injectors into a more powerful burner.Bike3DWork withZucrowThe laboratory further consults to help them use3DPrint “do what you want “The possibility of integrating groups of injectors into one3Din the print component.

From there, engineers will continue to refine and assemble a complete burner system, with the technology targeting the2022By the end of the year, hypersonic testing capabilities will be fully exploited.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.