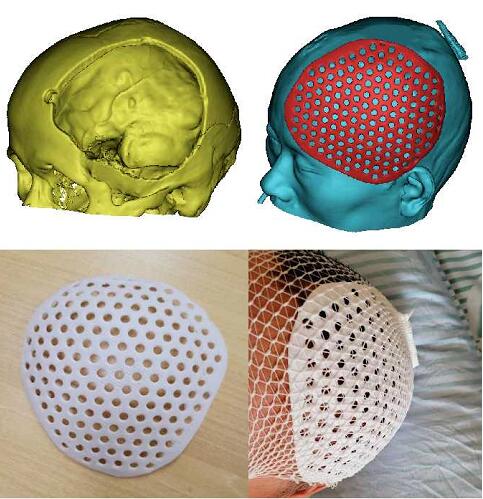

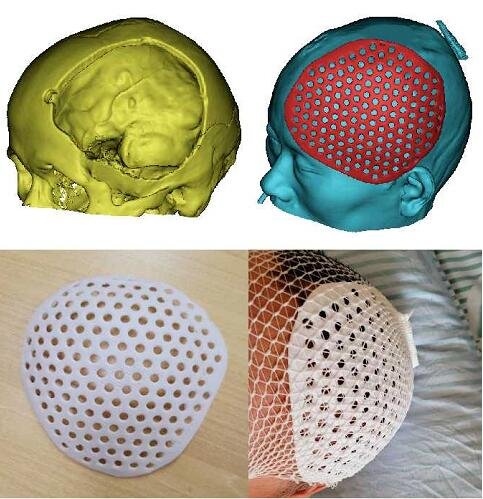

Recently, according to Mohou.com, the craniocerebral trauma team of the neurosurgery district of the high-tech campus of the First Affiliated Hospital of Anyi University and the Clinical Digital Medicine Transformation Center successfully customized a patient with a skull anomaly.3DPrint “protective cap”.

3DPrinting “protective caps” for skull defects© Anhui Business Daily

The patient got through the period of skull malformation safely and without problems

The patient, Mr. Dou, went to the Neurosurgery Department of the High-Tech Campus of the First Affiliated Hospital of Anyi University due to subdural effusion following cerebral hemorrhage.“Postoperative cranial defect20Yutian, chefCTIt indicated a right-sided subdural effusion and a personalized protective device against cranial defects was considered. “According to Mao Xiang, deputy chief physician of the neurosurgery department of the hospital, after communication between the neurosurgery department and the Clinical Digital Medicine Transformation Center, the three-dimensional image of the patientCTData-driven, through custom design and3DUsing printing technology, a “protective cap” against skull defects was tailor-made for him.

After Mr. Dou wore it for a week, upon examination, the interhemispheric effusion was reduced compared with before, and the intracranial structure basically returned to its physiological and anatomical reset.

according toUnderstand that the “protective cap” is placed on the patient’s headCTContinuous thin-layer scanning is used to construct a three-dimensional reconstruction of the patient’s cranial defect from the acquired image data, thereby achieving a close relationship between the reconstructed model and the real head.100%The customized matching design adopts polymer materials with suitable hardness and toughness and good anti-collision effect which can effectively resist and disperse impact forces.PLAPolylactic acid, the cap body is light (not enough100g), and provides good comfort at the same time, hospital-independent design and printing ensure the speed of clinical application.

Mao Xiang said patients with skull abnormalities after surgery generally need a recovery period of about three months before skull repair.“But the three-month period with a cranial defect is very difficult for patients because the brain tissue in the defect area loses the protection of the skull. Strict precautions must be taken to avoid collisions in daily life. In addition, Subdural accumulation may occur due to the pressure imbalance of cerebral effusion Fluid production and hydrocephalus.

And for each patient3DPrinting a personalized “protective cap” can better fit the skull defect, protect brain tissue, prevent hydrocephalus and subdural fluid accumulation, promote brain tissue repair, and help patients patients to return to normal life as soon as possible. They offer a solid security guarantee. and a smooth transition through the skull defect period.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.