Recently, the science fiction comedy “Walking on the Moon” produced by Mahua Pictures topped the box office28.79100 million, becoming the first successful case after the establishment of the scientific and film integration project.The production process involved the participation of scientists and engineers from China Aerospace and the Chinese Academy of Sciences.

Can the integration of science and film pave the way for the continuous production of excellent domestic science fiction films?

Full use3DAn impression comparable to an automobile factory

When “Walking Alone on the Moon” was released, audiences expected to see a comedy. After watching it, they discovered that it was a solid science fiction film.

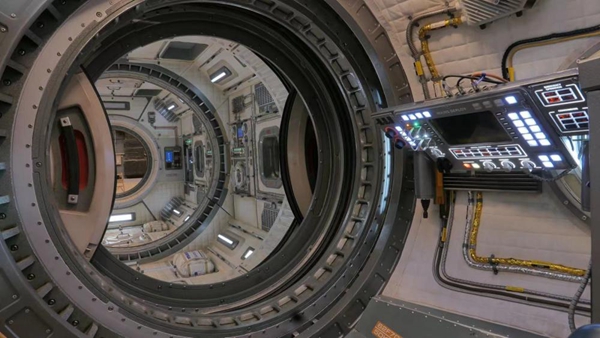

Most of the film takes place in a space environment. Rocket launches, moon bases, space stations, nuclear bombs, meteor belts, etc. are not ridiculous or simplified because of comedy, but the scenes are beautiful, the details are in place, and the sense of reality is even overwhelming. classify it as“Hardcore science fiction”.

Some Internet users wrote:“The picture is very professional. I guess there must be professional advice. When I saw the end of the film, I found that the first unit to be let go was the Information and Publicity Center from the National Space Administration Space promotion is getting better and better, and science fiction movie fans are in heaven.”

Actually, it’s not just about the long list of credits at the end of the film. To be precise, this is the first time that a domestic science fiction film has appeared clearly.“Scientific advisor”. This is also the first successful case to be published after many years of integrating science and film.

2020In 2017, the “Several Opinions on Promoting the Development of Science Fiction Films” jointly issued by the National Film Administration and the China Association for Science and Technology pointed out that a scientific advisory library for science fiction films -fiction should be created to provide professional advice, technical support and other services for science fiction films.

However, it is not easy for those in the film and television industry to find scientific experts as consultants. In the middle we need a“bridge”.

2020At the end of the year, the Science, Film and Television Integration Committee of the China Popular Science Writers Association was officially established, hoping to build a platform for dialogue fluidity and close cooperation between the film and television industry and the scientific community.

Also2020In 2019, “Walking Alone on the Moon” had just completed the project and formed a creative team. Director Zhang Chiyu, art director Li Miao, and visual effects director Wei Ming are all true “sci-fi fans”. Having grown up watching various science fiction works, they decided to make “Walking Alone on the Moon” a true science fiction comedy.

As a science fiction fan, I understand the public’s mentality, so the pressure is particularly strong. The team is very clear that the biggest challenge for domestic science fiction films is——Our audiences are already very familiar with Hollywood sci-fi blockbusters and have already developed an appetite for high-investment, high-cost blockbusters from around the world. Domestic science fiction films have just started, but audiences will directly compare them to Hollywood blockbusters. In other words, there is no opportunity for growth in the middle.

Start from scratch. Li Miao studied a large amount of Apollo lunar exploration materials and space station design materials, many of which were in foreign languages.

According to data, lunar dust can interfere with precision electronic instruments, so the air-conditioned cabin at the entrance to the Lunar Shield base he designed has dust collection equipment. The lunar rover must be strictly dusted when entering the base indoors. pityThe details of the “dusting” were ultimately not strongly integrated into the feature film.

anyway,“There is still too little information available and it is difficult to find it in bookstores and on the Internet,” lamented Li Miao. Domestic science fiction films lack experience and start from scratch.

For example, the first version of the Moon Shield Base interior was tested for two months, but the effect was not satisfactory, so it had to be scrapped and remade. Movie sets are usually made of wood and then painted, but no matter how sheen the paint, the edges and corners remain soft and don’t have the texture of a space capsule.

After two months of invalidating the results, Li Miao decided to adopt a large number of3DPrinting components, some detailed parts are printed using nylon material. Even though the cost is high, the scene has a more industrial texture.

This time, almost all scenes and vehicles have been produced.3DPrint templates. Every time a new plan is discussed, a new template can be printed quickly.

Li Miao’s team purchased several different types of printers, divided intoPLAnylon, photosensitive resin and other materials.

Some of the things in the image that audiences thought were visual effects were actually real devices made by engineers. For example, the lunar rover’s gullwing doors are truly controllable with the press of a button. There are also lighting systems for nuclear bombs etc., all custom made by mechanical engineers.

go through3DOnce the models are checked, the art team hands them over to the visual effects team to create digital models. Then there was another step that regular films don’t have: several months of virtual filming.

This is equivalent to digitally simulating the planning and effects of all shots before real people join the crew to begin filming. Post-production, pre-production and pre-setting, smooth communication and close connection between different departments.

“It’s like setting up an assembly line in an automobile factory,” Li Miao said with a smile.

3DThe printing workload is so large that it is even outsourced to several companies in Shenzhen.3DPrinting factory. “Walking alone on the Moon” could be the first large-scale application of its kind in China3DPrinted film team.

These steps mark the beginning of the Chinese film industry.There is practically no violation of scientific principles in the general sense.“Looking back, if we had intervened earlier, we could have given the team more professional resources,” lamented Wang Shu, deputy director of the Science, Film and Television Integration Committee. China Popular Science Writers Association.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.