located in MadridIMDThe Materials Research Institute is developing new onboard sensors capable of monitoring aircraft in flight in real time. In order to achieve optimal performance and perform the best functions, researchers chose3DPrinting technology for manufacturing. Thanks to the uniqueness of this technology, humans can fly more safely because3DPrinted sensors are more predictive and easier to maintain, with the ability to notify maintenance teams of problems before a devastating accident occurs.

3DPrinting aircraft sensors

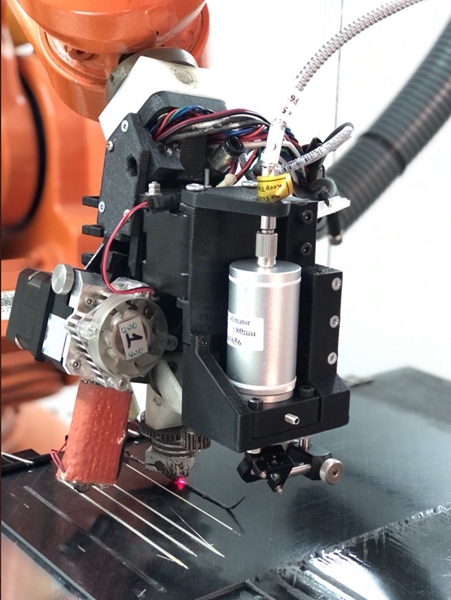

This work is called“Digital methods to improve the manufacturing of next-generation multifunctional cell parts (DOMAIN) » project, by Horizon 2020 Funding of research projects.IMDteam3DParts printed with embedded carbon nanotube fibers. The piezoresistive properties of carbon nanotubes can be used to generate relevant data and be used to monitor parts.

Additive manufacturing (AM) Assembly costs can be reduced while eliminating the large number of wires needed to connect sensors together. According to statistics, there are70arrive300Kilometers of wire would require approximately100arrive400A wiring harness holds the sensor in place, reducing the number of necessary and cost-effective cable connections.3DThe printed sensors are also lightweight and consume relatively little power.

IMD Materials researcher Moises Brambleclaw emphasizes: “The sensor materials are made of very light fibers and consume very little energy compared to existing materials.3DPrinted, it easily integrates into traditional carbon fiber parts, a material very commonly used in aeronautical production. “

From sensors to digital twins

The key to the project is the use of digital twins(It fully exploits data such as physical models, sensor updates and operation history, integrates multi-disciplinary, multi-physics, multi-scale and multi-probability simulation processes, and completes mapping in the virtual space to reflect complete life. cycle process of the corresponding physical equipment.)An aircraft simulation model was created.IMD is a leader in this field, using information collected from embedded sensors to create digital twins of physical parts.

brambleExplains: “They are called digital twins because they are very precise digital models that are updated throughout their life cycle, replicating in real time the physical part or assembly within the aircraft. Thanks to its integrated sensors, the physical part is able to communicate directly with engineers on the ground communicating, for example, if you are flying. If the process is affected by hail, the sensor will record information about possible damage to the component and then automatically send it to its digital twin. With this information, the simulation we are developing will be able to analyze potential impacts that could cause structural damage. the integrity of the component and determine its remaining life.

pass 3D Smart sensor printing improves aircraft maintenance

With this technology, airlines can not only fly safer, but they can also reduce costs in a variety of ways, including: more accurate maintenance intervals, reporting problems before they cause delays flight, as well as component monitoring and analysis. Real-time monitoring enables a completely new way of looking at sensor-based aircraft maintenance, rather than the schedule-based approach used today.

Event-based signals can become an important part of monitoring the cell and its components. Researchers can develop protocols to look for telltale signs of impending failure or conduct specific monitoring in the face of different events. Knowledge of an in-flight malfunction could even allow crews to land preemptively, shortening a flight that might have crashed hours later due to a critical component failure.

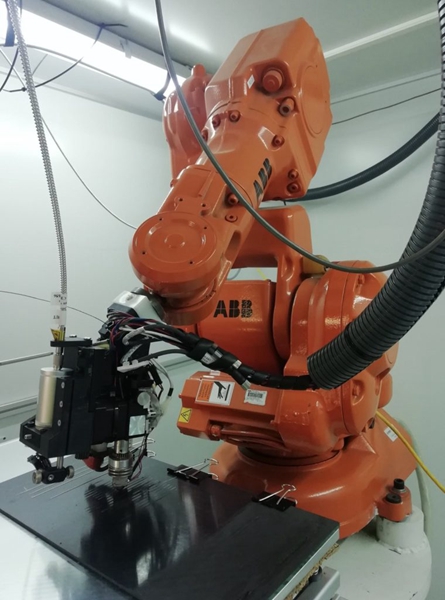

Many aircraft parts are now 3D Printed composite materials. Integrating carbon nanotubes while using a robotic arm to fabricate components appears to fit well into the overall workflow. For metal materials you can use something likeFabrisonicsultrasoundAMSensor integration technology, which does not use heat during the object printing process, ensuring the success rate of sensor manufacturing. Many nanoprinting companies also offer tools for deformation, vibration, pressure, etc.3DPrint the entire sensor.

It is obvious that integrated sensors are useful for critical and high-value objects or processes, such as dams or aircraft. For this type of objects,3D Printing can provide a cost-effective way to manufacture integrated sensor packages and integrate them into our world.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.