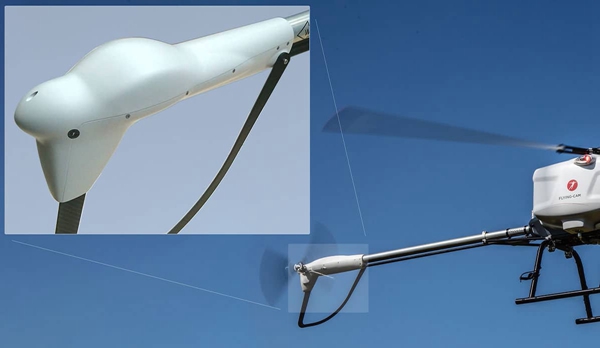

2022Year9moon25day,FLYING CAMERAAnd3DPrinting equipment and service providersCRP technologyCooperation, new dronesDiscoveryto use3DPrinted parts to reduce the weight of the tail rotor gearbox.

△FLYING CAMERANew drone, already adoptedCRP Technology 3D ModelComposite powder bed fusion printing(FBP)Craftsmanship

FLYING CAMERAis a manufacturer of single-rotor unmanned helicopters and a pioneer in professional drone photography services. To celebrate the creation of the company.30The latest drone launched on the occasion of the anniversaryDiscoverycooperated with long-term partnersCRP technologyContinue to collaborate by adoptingWind Shape XT 2.0Made of composite materials3DThe printing and weight reduction of the new structural parts aims to provide a better flight experience.

DiscoveryNew single-rotor drone

The drone has a maximum take-off weight of(MTOW) For75One-kilogram unmanned single-rotor helicopter, largest yet FLYING CAMERAThe largest and most versatile product with higher battery life.FLYING CAMERAUsed in manufacturing the tail rotor gearbox housing of this droneCRPtechnology, that is, the main hull connected to the main tail boom.

FLYING CAMERAFounder and CEOEmmanuel Previnaire He said: “With the potential demand for drones in the civilian market and the demand for beyond visual range flights,(BVLOS)We believe now is the right time to develop drones that can not only capture beautiful images for films, TV shows and commercials, but also carry various payloads to collect the data needed for projects such as other industrial applications.

He then explained:“SO,FLYING CAMERAI created this product calledDiscovery The “Super Drone” is fully integrated with cutting-edge sensors carefully selected to match the highest quality platform for a variety of applications including the entertainment industry, homeland security, Earth monitoring and general high precision needs. “

The objective of the company is toDiscoveryTail rotor actuators for single-rotor UAV helicopters, andGPSThe antenna creates an aerodynamic enclosure that is lightweight but at the same time sufficiently durable.

△New drones3DOnce the weight of the printed structural parts is reduced, they retain sufficient strength, with the aim of achieving stronger flight capabilities.

This drone is3DPrint a part

satisfyFLYING CAMERArequirements and standards, selectedCRP technologyExclusive high performance Wind shape top lineseries of composite materials, includingWind Shape XT 2.0which is a polyamide loaded with carbon fiber based on3DPrinting of composite materials, particularly for motorsport, aeronautics and drones.Wind shapeThe mechanical and thermal properties of the material are linked to3DThe characteristics of the print manufacturing process are closely related. In fact, the combination of the two produces unprecedented cutting-edge technology.3DPrint parts.

PrevinaryTo further emphasize, “CRP technologyprovided3DPrinting process and composite materials, with comprehensive innovation and design, which is important for aerodynamics, as well as the ability to create complex routing channels with strong connection points inside, and most importantly, It can create detailed hollow parts such as embedded nuts and cable connection points with many functions. It was an advantage that matched our needs and criteria very well. “

△SARAH 4.0 flying cameraSingle-rotor unmanned helicopter deployed in NetherlandsAEROSCANCompany selection

3DPrinting Technology Partner

Years ago we started working withCRP technologyCooperation, achievedSARAH 3.0Smart drones, our electric vertical takeoffs and landings (VTOL) Unmanned aerial vehicle systems are nowSARAH 4.0replace.PrevinaryExplanation: “ByCRP technologyQualified, we3DThe fuselage structure, air cooling system, fin and main battery connections were printed. In fact,SARAHAndDiscoveryThese are all cutting-edge “drone intelligence” solutions, which can only be achieved by mastering all relevant technologies and skills. “

2014Year,FLYING CAMERAunderSARAHWon an Oscar for science and engineering.Previnary He said: “We are professional, we have obtained2Oscars and1Emmy Awards, but this specific technology award makes us proud as it once again demonstrates our professional approach to always strive for excellence and apply general aviation flight knowledge and skills. “

He finally said:“This exceptional approach will not only continue to drive the company’s engineering efforts, but will also guide our selection of manufacturing partners, however, they must demonstrate that they are on the same page as us.”SARAHFrom the beginning we will3DPrinting expertCRP technologyCooperation so far. “

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.