JWSpeaker CorporationFounded in1935Providing high-performance lighting equipment for automobiles, motor vehicles, transportation vehicles and industrial locomotives, the company focuses on providingOEMAftermarket manufacturers and customers develop innovative productsDIRECTEDand new lighting technologies.

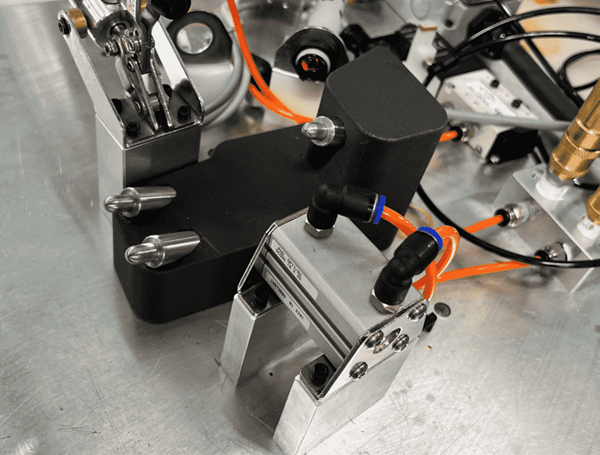

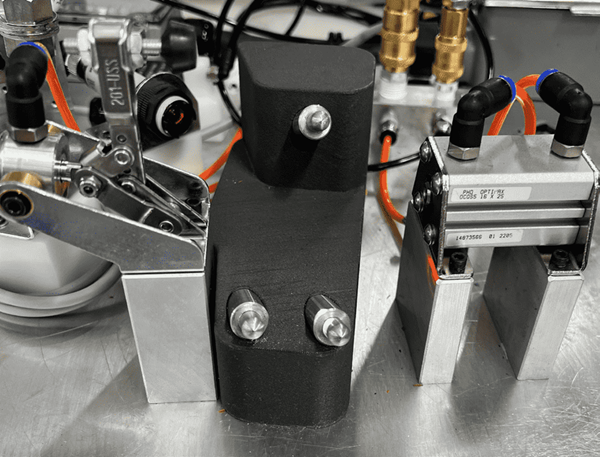

Lights manufactured for snowmobiles must be leak tested to verify their ability to be waterproof. The luminaire used for testing must be able to withstand100pounds of force, as air must be extracted from the fixture housing to ensure a perfect seal. Custom fixtures are usually machined from aluminum, but this requires purchasing raw materials and usingCNCMold machining. While this solution works, engineers want to be able to get the device up and running more quickly.JWSpeakerInstead of machining, tool designers useFDM®Nylon-CF10Carbon fiber composite materials come3DPrint fixture. It is a nylon-based composite thermoplastic material filled with10%of chopped carbon fiber. Harder, more durable material for more demanding applications.Nylon-CF10Available atF370®CRUsed on composite printers which can also print other composite materials as well as engineering grade polymers.

3DPrint fixture moldsJWSpeakerMold production time is reduced by approx.80%——Two days shortcut to10Hour.Nylon-CF10AndF370CRIts capabilities for printing on composite materials also give it the freedom to design molds on demand, without being limited by traditional treatments. This process can quickly complete product iterations and bring a more flexible mold design process.

source:Stratasys

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.