2022Year11moon1Japan, Texas (AM) researchers at the university use3DPrint and salt to create eco-friendly polymers that degrade naturally over time. Associate Professor, Department of Materials Science and Engineering and Department of Chemistry, University of TexasEmilie PenzerPh.D., uses a process that allows polymers to degrade naturally over time.3DPolymer printing is more environmentally friendly. The study also received funding from TexasAMSchool of Engineering, Engineering Experiment Station, Department of Chemistry andCashmerewith the joint support of university researchers.

△Environmental pollution caused by plastic waste is shocking

△Researchers want more environmentally friendly salt to replace plastics

Dealing with microplastic pollution

Most commercial synthetic polymers are typically composed of large molecules that do not break down under normal conditions. When left in the environment, manufactured products like Styrofoam cups or plastic containers break down into small pieces invisible to the naked eye, but the long polymer molecules remain forever.

think“It’s not just the problem of plastic bottles being thrown away, it’s also the fact that these materials break down into microplastics which remain in the environment. We don’t fully understand the impact of microplastics, but they have been shown to carry disease. heavy metals, fecal bacteria and other harmful substances.

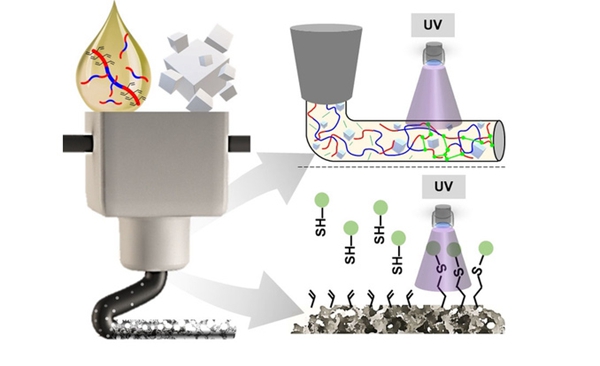

△Degradable materials synthesized with tailored thermal and mechanical properties via a two-step one-pot strategyCO2Based on triblock polycarbonate. WillNaClParticles dispersed in polymer solutions can be formulated and3DPrint with thixotropic ink. Subsequent removal of the putty creates a porous structure

Salt3DPrinting degradable polymers

thinksaid: “Our goal is to create degradable and durable polymer structures, and we do this by taking advantage of the microstructure provided by chemistry and3DPrint the provided macrostructure to do this. “

To create degradable polymers,thinkProfessor Emeritus, Texas Department of ChemistryFor DarensburgDoctors team up to use carbon dioxide and table salt to create3DInk for the printing process. After printing, the structure is washed with water to dissolve the salt and solidify the structure. Although the exterior of the structure still appears smooth, the process creates thousands of tiny pores that allow the compound to degrade more quickly. At the same time, the olefin pendant groups on the polymer backbone can pass through the UV-induced thiol.–The alkenes are then modified by surface functionalization and cross-linking.

thinkexplain:“Under the right conditions, the polymers we create degrade quickly, ideally breaking down into small, non-toxic molecules. Most importantly, these small molecules cannot carry things like heavy metals or bacteria.

Potential applications

As research progresses,thinkThe hope is to use this process to create packaging materials so that items like boxes and tape can degrade quickly rather than being buried in landfills for years. She also saw3DPrinted polymers have a bright future in biomedicine.

think“These materials can be used in various biomedical applications. Things like implant scaffolds will degrade over time so your body can heal, but you won’t have that piece of plastic forever,” she said. explain. “It’s a bit like bringing science and engineering together. By working together, we can create synergies and achieve more.” Through the team’s interdisciplinary research, they look for potential impact on the environment, human health, biomedicine and all aspects of human existence, solutions that could have far-reaching consequences.

Source: Antarctic Bear

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.