USA3Dprinter manufacturer3D systems(DDD) announced with Swedish OEMWe countReached strategic cooperation and became the company’s selective laser sintering (SLS) Exclusive global distributor.We countIt is one of the few specialty products on the market with relatively low manufacturing costs.SLSOne of the equipment manufacturers.

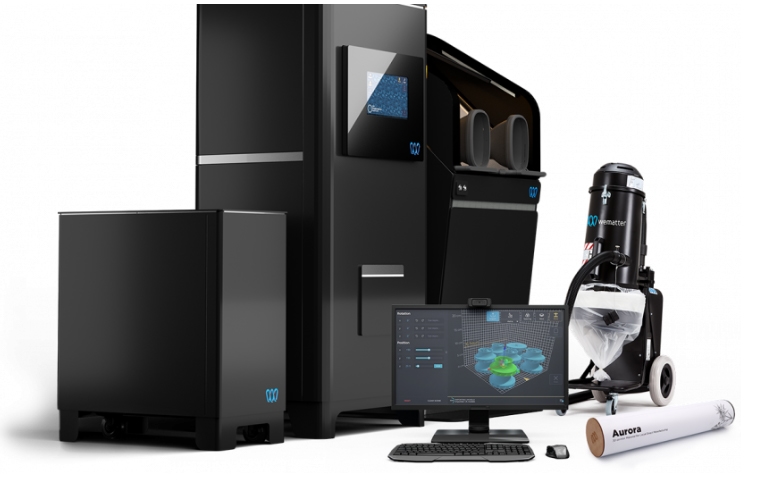

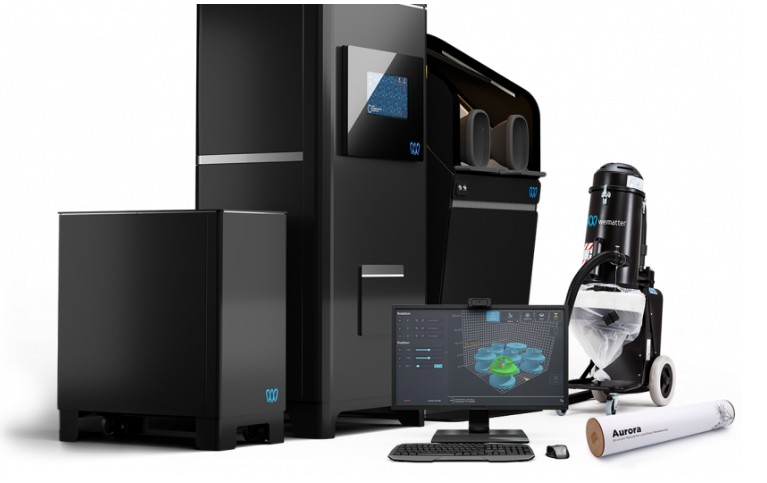

△Wematter Gravity SLS 3D Model Printer and its ecosystem

This time there is no acquisition but cooperation

We countPresidentRobert Kniolacommented: “With the help of3D systemsThrough our existing brand effect and sales channels, we can provide services globally, makingWe countbecome3DAffordable and easy to use in printingSLSsolution. “

Wematter Gravity 3DThe price of the printer is9million euros (approx.63Ten thousand yuan), can be used in laboratories, hospitals, universities, printing houses, etc. he has0.7mx 0.7mx 1.5msmall footprint while having300mm x 300mm x 300mmThe powerful construction volume of, which, according to the partners, is three times larger and three times smaller than “comparable solutions”.

This is a smart decision for both companies, as it allows3D systemslower cost of entrySLSplatform,

Without committing to building a new system or acquiring another company. And, likeWe countAs the president noted, the Swedish equipment developer benefited from3D systemsStrong presence and global customer base.

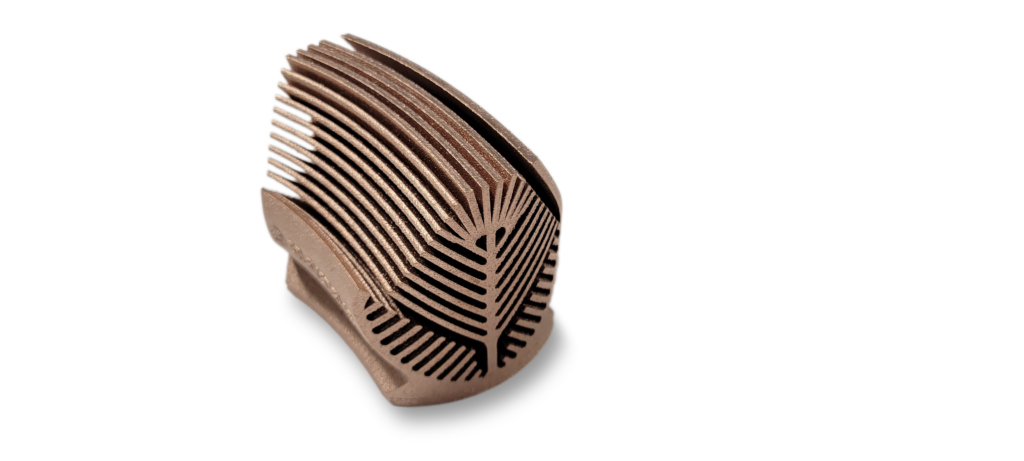

△In3D systemsofDMP Flex 350use certified productsCuCr2.4Material3Dprinted radiator

New metal3Dprinting equipment

Also,3D systems Announcement of the availability of two new metal powders: a certified nickel alloyHXwhich the company says is ideal for producing tall parts with integrated cooling and flow channels, and certified copper alloyCuCr2.4which is suitable for thermal management and cooling systems. New materials and3D systemsofDMP Flex 350AndDMP 350 factoryCompatible with the platform and, at the same time, certifiedHXYayoDMP 500 plantcompatible.

approvedHXIs a nickel alloy with a higher molybdenum content than other nickel alloys (up to9.5%), which can improve its strength and resistance to corrosion, creep deformation, cracking and oxidation in hot zone environments. Modified materials are suitable for1200°C High temperature environments such as industrial gas turbines, petrochemical and military applications.3D systemsSeveral examples are given, including “applications such as hot zone stator blades and integrated stators, turbines, turbine blades, drilling tools, and combustion components.”

CuCr2.4Is a high-strength, corrosion-resistant copper alloy that is stronger and easier to work with than pure copper. This material has99.9%Its high density and high conductivity make it a special functional material that requires high strength and conductivity. This material can be widely used in industrial, automotive, aerospace and defense consumer goods applications.

3D 3D SystemsExecutive Vice President, Printing and Chief Technology OfficerDavid LeighCommenting on new materials: “Defining the right solution begins with our teams working with customers to select the best materials to meet the performance and mechanical properties required for the part. The continued development of materials will help to increase the number of solutions to be satisfied. to our customers’ needs, enabling them to accelerate innovation and maintain a competitive advantage.

△InDMP Factory 500 3D ModelOn the printing device, use aHXMaterials to build industrial gas turbine components

The goal is not low cost3D SLSprinting market

The latest collaboration between the two companies could involve3D systemsThe introduction of two new materials is somewhat related, althoughWematteofGravityIt is a polymer platform. It is reported that, but in recent months devoted toFMC 3DprintedSLSTrade Association of Original Equipment ManufacturersColdMetalFusion (CMF) and now the number of alliance members is growing rapidly.FMCIt is even permitted toSLSThe platform is used for the output of metal bits.

in this case,We countOne of the main competitors of Swiss equipment manufacturersSintratecjoined the alliance, but it should be noted thatWe countNot joined yet. It should also be noted that the founders of the allianceHandmade materialsYesAM Venturesportfolio companies,SintratecThe same is true. This does not mean3D systemsplan toGravitybecome a low-costSLSmetal platform to createFMC AllianceThe US rival simply said the company had a foot in the metals and polymers camp and would be well placed to do so. Additionally, copper and nickel alloys are two types of alloys that appear to be related toFMCPrint compatible materials.

At this stage, for3D systemsThe introduction of new materials is timely. Because they increase the company’s potential to exploit any potential emerging market for electric vehicle batteries in the United States. taking into account3D systemsThe fact that the factory is located in South Carolina is particularly advantageous. According to state senatorLindsey GrahamAccording to the report, South Carolina is poised to “become the Detroit of Batteries.”

anyway,3D systemsThe latest announcement reminds us that with3DAs the printing market continues to grow, the industry has never stopped innovating. For companies with decades of experience in the field, they seem to have the same ability to learn and innovate as startups.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.