in bigFBPmolten metal on powder bed3DIn the field of printing,GDT SolutionsWithout a doubt one of the best.According to Mohou.comthe latest version of the company based on 12 LaserNXG XII600E 3D Model The build volume of the printer is 600x600x1500mm,exist Z The machining dimensions on the shaft have reached1.5meters and I received itCompeting Technology Company (CTC) first order.CTC is the prime contractor for the US Air Force Research Laboratory (AFRL) project.AFRL Funding of this work to use additive manufacturing for advanced purposes Ministry of Defense application.

Already installed or about to be installed NXG XII 600 customers can benefit from a scalable architecture and have the ability to upgrade their systems to unlock expansion Z Build size advantage.NXG XII 600E expected in 2023 Annual delivery as planned. However,GDT SolutionsThis equipment is still partially inferior to some Chinese manufacturers in terms of processing size limitations:

Eplus3DThe new nine laser developedEP-M1250 Metal3DThe printing system has a build volume of 1258x1258x1350 mm.

The very large metal of platinum3Dprinting equipmentBLT-S1000The size of the forming cabin is increased and the forming size can reach1200mm×600mm×1500mm(except170mmthick substrate size), standard8Laser, optional10Laser and12Laser, same part12LaserBLT-S1000The forming efficiency can reach300cm3/hour。

△NewNXG XII 600E

SO,GDT Solutions The decision to push the boundaries of manufacturing even further with the next revolutionary solution is changing metal again.3DPrint size. This revolutionary solution will be capable of producing sizes up to 3.0 x 1.2 x 1.2 meters (long x Width x High quality metal parts, thus shaking up the entire industry. The large machine consists of a central unit and a dimensionally flexible construction shell, allowing the manufacture of components of different sizes. combine GDT The game-changing advantage of technology offers users the possibility of perfectly customized production for individual needs.

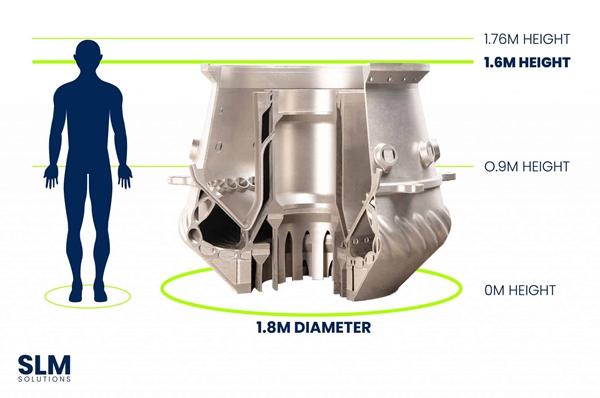

Additive manufacturing has often reached its limits when it comes to the size of build chambers. Often large rooms cannot be built because they exceed the installation space allowed by the market. Flexible systems solve this problem and will provide a huge boost to the entire additive manufacturing industry. For example, it allows the production of diameter1.8Meters, height1.6meters of cylindrical parts, or sizes up to3.0 x 1.2 x 1.2Pieces one meter long. It can therefore reach up to330cubic centimeters/Hours of manufacturing speed.

△Rocket engine nozzle expansion part, material: stainless steel, size:1050x160mmprinting time:160 hours. Application: Aerospace

GDT SolutionsCEOSam O’Learyexplain:“This is yet another revolutionary technology that opens new possibilities for transitional additive manufacturing applications by removing geometric constraints. Every technology we develop is the result of an exceptional team solving our customers’ manufacturing challenges and changing the future of manufacturing.“

The new solution enables the additive manufacturing of large metal parts while offering traditional solutions;GDTAll the advantages of technology, such as freedom of design or the reduction of several parts into one. Finally,Sam O’Learycommented:“it’s not onlyGDTA simple addition to the solution machine range. This is a real revolution in the manufacturing sector. We can’t wait to show off the huge, giant metal pieces that are almost unbelievable, but don’t you dare challenge yourself.“

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.