recently,According to Mohou.com,Manufacturer of automated post-processing systems Post-processing published his 2022 Year 3D Results of a survey of post-print processing trends.

Post-processing technologies,YesThe first dedicated to AM Company developing fully automated post-press solutions, connecting end-to-end digitalization from the design stage to the post-press stage. With the industry 3D Printing is developing to support the industries of the future 4.0 In the factory, this connection is essential for additive growth and mass production. 3D Printing will only become more necessary. It is Post-processing According to ‘s fourth annual survey, results show a significant increase in demand from manufacturers in two areas, including better managing labor shortages and meeting the Sustainable Development Goals. In terms of post-processing, the company also discovered3DThere is a clear trend towards secondary print processing and users are increasingly questioning whether current products are suitable for their enlargement needs.

Post-processing marketing director Melissa Hanson He said: “I often hear post-processing referred to as the ‘dirty little secret’ of additive manufacturing, but that’s not the case. 3D Printing and manufacturing large components can improve the accuracy and quality of parts. We are excited to continue our mission of bringing together 3D This critical step in the printing workflow is brought to the forefront and current post-processing trends are analyzed, which is essential for the rapidly evolving materials industry. “

What is the Post-Print Processing Trends Survey?

Over the past four years,Post-processing Feedback from users of the post-processing system is solicited through its annual industry-wide survey. Using the resulting data, the company summarized and compiled industry reports showing 3D The most common post-processing methods for printed parts and how factors like post-processing costs and delivery times continue to change.

[h ] previous Post-processing The investigation reveals a relationship between resin removal and surface preparation, and 3D Trends in print batch manufacturing. Based on these findings,2022 The 2018 survey produced a more in-depth analysis, revealing other key trends that the company says will “provide a much-needed resource” for mapping a fast-paced and evolving industry.

2022The data in the 2018 report is relatively reliable and its data samples are extremely rich. 34% of respondents use 3D In print for a decade or more. In terms of demographics,83% of respondents come from the United States and Europe, while 9% Now operating in Asia-Pacific (up from two years ago) 0%), the three main participating industries are medical, machinery and manufacturing. .

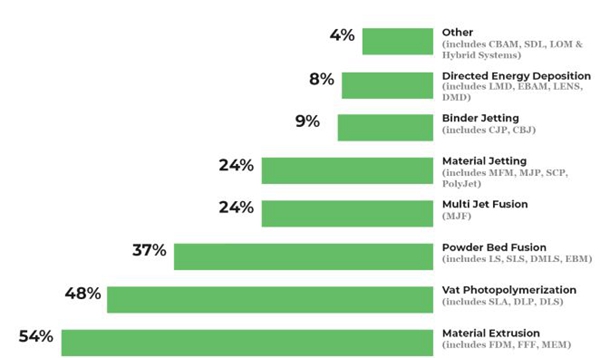

△Pass Post-processing A survey collected information on adoption 3D Printing technology data.

Post-discovery treatment challenges

Mainly adopted by users3DIn terms of printing technology,Post-processingThere was no change from last year, with material extrusion becoming the most popular technology. Interestingly, however, this year’s report identifies stereolithography and powder bed fusion. (FBP) Transformations in final production applications include 48% And 37% of respondents use these applications.

The report also indicates that the number of manufacturers using two or more printing technologies remains stable at50%or, this year, it will reach57%。 FBP Users say their challenges have also changed: two years ago, their main concerns were labor costs, part damage and throughput. Today, not only do they have to deal with personnel problems, but they are increasingly concerned about the environment and waste management. FBPUsers currently have an urgent need to find a suitable workforce for mass production.

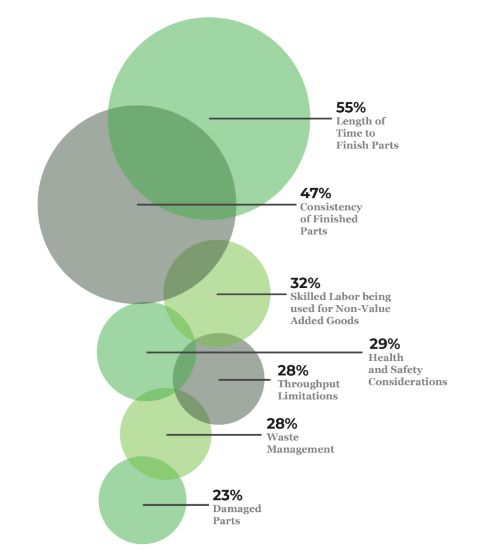

△Post-processing Participants in the latest survey consider post-processing challenges the most important.

In terms of post-processing his survey,Post-processing It was found that the same three techniques remain most commonly used: Removal of support (54%),remove the resin (42%) and surface treatment (39%). Post-processing is also seeing a growing trend in “secondary processes” such as steam smoothing, dyeing and curing.

The report also highlights some of the current challenges faced by users of post-processing systems. For the third year in a row, the time needed to complete a part is the number one concern among respondents (55%)during treatment 3D Printing products are respondents’ second biggest concern (47%)。

Finally, when asked whether current post-processing methods help or hinder their 3D When printing targets, most contributors said they required post-processing techniques. Users of production-oriented technologies, such as long powder melting, material jetting, photopolymerization, and directed energy deposition, also view part finishing as an issue and, as they expand , post-processing technology could become an even bigger bottleneck in the future.

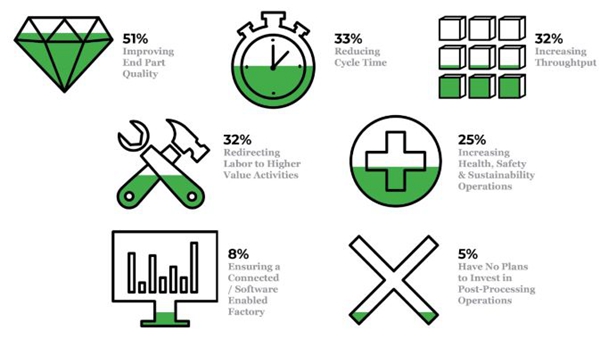

△Key considerations that influence users’ decision to invest in post-processing technology

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.