Due to its potential to be more sustainable and environmentally friendly, additive manufacturing technology is beginning to receive increasing attention from the manufacturing industry.2022Year12moon18day,According to Mohou.comfrom the Technical University of Hamburg (HHH) A research team is carrying out a project entitled “Green 3D “Print” project. This project is provided byProf. Dr.-Ingleader, striving to convert waste paper such as egg cartons or egg paper that are thrown away everywhere in life into3D Printing materials to create more durable prototypes and models.

plastic is3D A common material in printing, it is often used to create prototypes and models. However, this creates waste, as not all raw materials come from sustainable manufacturers and are often thrown away once the prototype is made. Considering that plastic waste is a growing problem worldwide, the U.S.-generated project 4000 Among the 10,000 tonnes of urban plastic waste 85% be transported to landfills,BUT researchers chose a more resource-efficient and environmentally friendly alternative to paper fiber materials.

Specifically,“Green 3D The “Print” project aims to explore the feasibility of printing using paper fiber materials. This paper-like material can be produced from discarded egg cartons that can be found everywhere in life. The project is funded by the Science Agency’s “Energy Transformation Initiative”. program, the total amount is26,300 euro, with a particular focus on sustainability.

△The first printed product made from paper fiber (photo source:BWFGB)

From old paper to finished product 3D printing equipment

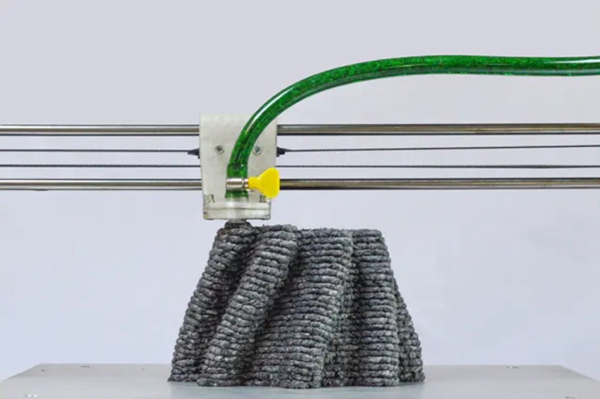

In order to be able to transform egg cartons3D To create the fibrous raw material for printing, researchers at the Technical University of Hamburg used individual paper fibers and mixed them into a fluid mass by adding water and a binder. Currently the team is working on the right combination of materials to ensure it can actually be used. 3D printer. If bioadhesives are also mixed, these additively manufactured prototypes can even be disposed of as organic waste. However,BUT The research not only involves the production of industrial prototypes, but also the production of end-use components and custom packaging that can be used for shipping.

△Dough3DPrinting and production

BUT The researchers are very satisfied with this project, because BUT President Andreas Timm-Giel The professor said: “The work we are currently doing, particularlyHERE Hamburg of YOU Project – “Green 3D Printing projects aim to find new sustainable solutions. This can significantly reduce resource consumption and lead us towards a more sustainable future. Specifically, we are testing the use of paper fiber composites 3D Print. This could provide a sustainable alternative to making plastic-based prototypes and concept models. The objective of this project is to develop a prototype system to evaluate its technical and economic suitability. “

The research group at the Institute of Laser and Plant Systems Technology at the Technical University of Hamburg is known for its work in the past. 3D Awards on the international scene for work in the field of printing: e.g.2014 German Economic Innovation of the Year Award for Industrial Metals 3D printed studies, and2015 Federal President’s Future Prize. For current production 3D They are also currently filing a patent application for the printing hardware project.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.