Binder jet (Binder jet printing)Metal3DPrinting has transformed manufacturing in industries such as aerospace and automotive, enabling the creation of high-volume and custom parts. As binder jet printing is combined with advances in software, artificial intelligence, and machine learning, engineers can reinvent how they use additive manufacturing in their work. From developing end-use parts to developing custom parts or repair parts that are often physically stored, metal jet adhesive printing will play a huge role in transforming factories around the world.

Some industry analysts predict that binder jetting may be the future of metal printing mass production. While there are many considerations and unknowns associated with adopting emerging manufacturing technologies on production floors, the use of metal binder jetting technology offers significant benefits.BJThe printing process is very fast, capable of manufacturing many parts simultaneously with great precision and accuracy, and the layer-by-layer printing process allows a high degree of control over the shape and size of the final object.

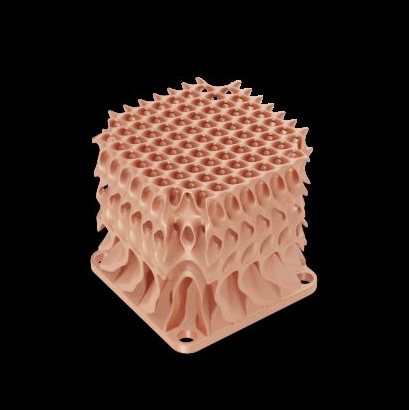

△Made of pure copper 3D Print the heatsink.

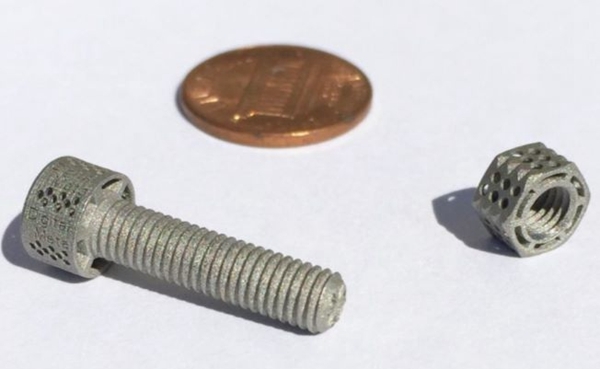

Binder jetting also makes it possible to print parts with complex internal structures and complex geometries that are difficult to produce with traditional manufacturing methods. This makes it an ideal technology for producing complex, high-performance parts for aerospace, defense, automotive and medical applications. Improved binders and better control of the printing process enable binder jetting metal 3D Printing is capable of producing parts with very high precision and a very high surface finish.Binder jet Metal 3D Printers are also now able to print much larger parts than before, allowing entire assemblies to be produced.

Software is driving advances in materials and printer technology. Many manufacturers are now able to use a single platform to control their entire shop floor, from the parts up.GUJATComplete automation from file to print. Software advancements allow manufacturers to store parts digitally rather than physically, reducing supply chain risks. If a certain part is needed, it can be sent to a local printer without having to be processed first, and then shipped to other areas. This significantly reduces costs and waiting times and increases profits in the production line.

△Meta digital of DMP2500。

predict2023From 2020, more and more manufacturers will use binder jet metal printing. As technology continues to evolve, binder sprayed metal 3D The printer will be able to produce parts faster and more cheaply, making it more competitive with traditional high-volume manufacturing methods. Entire industries such as automotive, defense, and aerospace are already rethinking how to manufacture high-volume, highly customized parts, with many engineers proposing to incorporate binder jet metal printing into their existing processes to increase efficiency and ensure that their factory will maintain a certain production. resilience for decades to come.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.