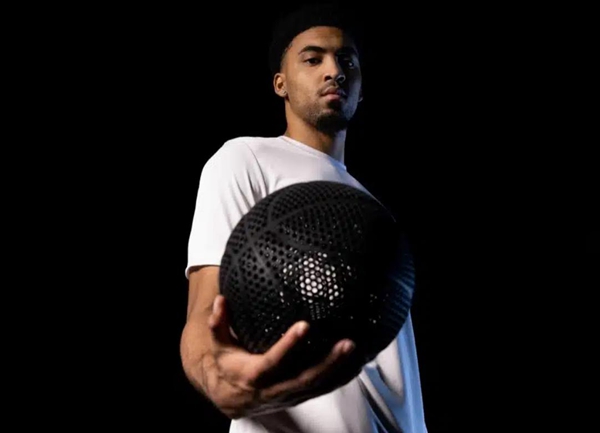

△On Saturday night, Houston Rockets player KJ Martin used this basketball in the first round of the AT&T Slam Dunk Contest.

The 3D printed ball is actually playable and almost meets the performance specifications of a regular basketball, including weight, size and bounce. However, the balloon does not need to be inflated, as it is made of a black, transparent grid with eight panel-like “pieces”.

In an official announcement, the Wilson Labs team completed the design of a 3D printed airless basketball prototype at the Innovation Center in Chicago, then worked with partners to manufacture it. General Lattice provides computer design services; Dyemansion provides 3D printing post-processing solutions; and the EOS Technology Center provides SLS 3D printing casting manufacturing, which is supported by AT&T’s high-speed fiber optic network.

The diameter of this 3D printed NBA basketball is 24.6 centimeters. Although it appears to be made of eight panel-like “pieces”, Mohou.com noted that it is actually 3D printed in one go and does not need to be spliced. It can be seen from the official video that there are laser beams and powder materials in the printing process, so it is determined that SLS laser sintering 3D printing technology is used and this technology is the one of the strong products of EOS, a major industry; a premium 3D printing company.

This type of SLS 3D printer now prints TPU, nylon and other elastic powder materials on a large scale. It integrates lattice structure design to produce seat cushions, shoe midsoles, insoles, helmet liners, etc. with elastic or cache properties. . terminal consumer goods. This basketball application is truly eye-opening.

If this All-Star Slam Dunk Contest in Salt Lake City can arouse the attention and use of 3D printed basketballs among basketball fans, if this cool and technologically advanced basketball is used in large quantities in the future, demand will reach hundreds of thousands per year. One, if not millions, will once again raise the depth and scale of 3D printing applications to a new level.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.