On February 28, 2023, according to Mohou.com, researchers from EPFL (École Polytechnique Fédérale de Lausanne, also known as Ecole Polytechnique Fédérale de Lausanne) achieved this. Specifically, they published a 3D printing method using inks containing calcium carbonate-producing bacteria. The resulting biocomposites have many interesting applications and are strong, lightweight and environmentally friendly. This research was published in the journal Materials Today in an article titled “3D printing of living structural biocomposites.” Links to related articles:

This is certainly not the first time that scientists have looked to the broader natural world for new additive manufacturing solutions. In fact, biomimicry, or the practice of imitating life, is popular in 3D printing because it allows for better optimization of parts, for example by mimicking the lattice structure of a honeycomb. There is a similar logic behind this project. Researchers turned to nature, where organisms are capable of producing composite materials that are both light and strong, porous and hard (almost impossible to make in a laboratory or factory), such as shells or mollusk bones. Ultimately, they hope to produce materials with these properties while being environmentally friendly. Now, with this 3D printing ink, that’s exactly what they’ve achieved.

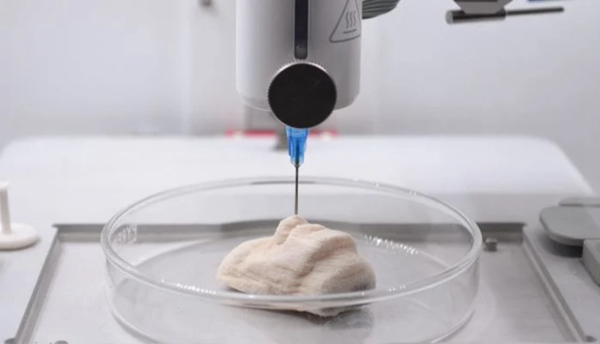

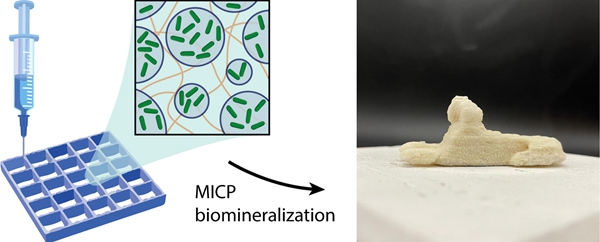

△By combining a bacteria-laden ink (called BactoInk) and 3D printing, scientists have succeeded in creating a strong, lightweight and environmentally friendly biocomposite.

3D printing bacteria to create better composites

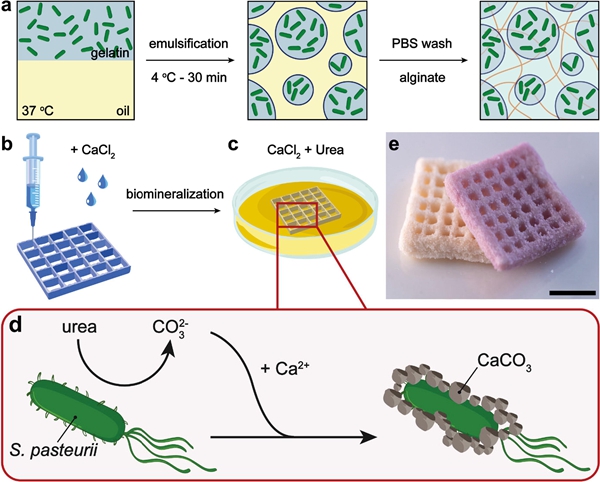

In a published article, researchers from the EFPL Soft Materials Laboratory 3D print biocomposites for living structures explain how they created this process. Namely, they created a 3D printable ink using Sarcosporum pasteurianus. This bacteria was chosen because of its interesting ability to trigger a mineralization process producing calcium carbonate (CaCO3) when exposed to solutions containing urea. The new ink, called BactoInk, can print almost any shape and then mineralize within a few days.

△Image Summary

The choice to use mineralizing inks arises from the need to solve problems typically centered around ink 3D printing (i.e. they can be difficult to manage as they require processing conditions). specific flow and tend to soften or shrink after printing). Esther Amstad, head of the soft materials laboratory, explains: “So we came up with a simple trick: instead of printing the mineral, we printed a polymer scaffold using BactoInk, then mineralized it in a second distinct stage after about four days. , the mineralization process initiated by the bacteria present in the scaffold produces a final product with a mineral content greater than 90%.

△ Matteo Hirsch and Lorenzo Lucherini, researchers from the Flexible Materials Laboratory, co-authors of the research project

The result is a biocomposite that is both strong and stretchable and can even be produced using standard 3D printers. In addition, the final product no longer contains live bacteria. This material is also particularly interesting because it is not only strong and light, but also porous, which is difficult to achieve in additive manufacturing.

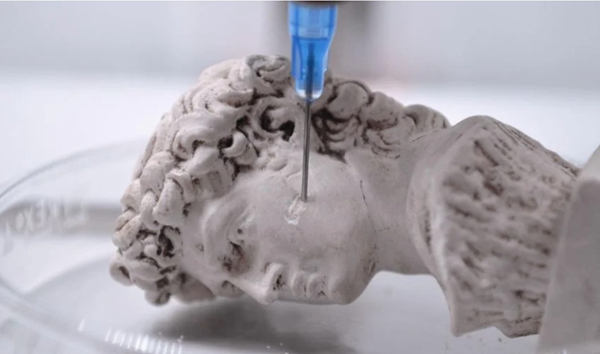

Researchers have described numerous applications for this material in different fields. One application is of course the restoration of artwork, as the ink can be injected directly into the site and then expand to accommodate any cracks or chips. But through the use of environmentally friendly materials, building artificial corals to regenerate damaged ocean reefs could also be very interesting as it is a pressing environmental issue.

△Restoration of works of art

Amstad concludes: “The versatility of BactoInk processing, combined with the low environmental impact and excellent mechanical properties of mineralized materials, opens up many new possibilities for the manufacture of lightweight, load-bearing composite materials, closer to natural materials than today. »

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.