Recently, according to Mohou.com, advanced manufacturing technology developer ARRIS signed a manufacturing contract with a new partner. The move will increase the company’s composite parts production capacity to more than one million units, expanding the company’s advanced manufacturing capabilities. influence. New contract manufacturing partners will also complement ARRIS’ facilities in California (R&D) and Taiwan (production).

About ARRIS

Arris Composites is a pioneer of next-generation composite materials for consumer applications including aerospace, automotive and consumer products. Arris, founded in 2017 by manufacturing veterans Ethan Escowitz, Riley Reese and Erick Davidson, develops continuous carbon fiber composites that can be combined with other materials in a high-speed process combining 3D printing and traditional high-volume manufacturing.

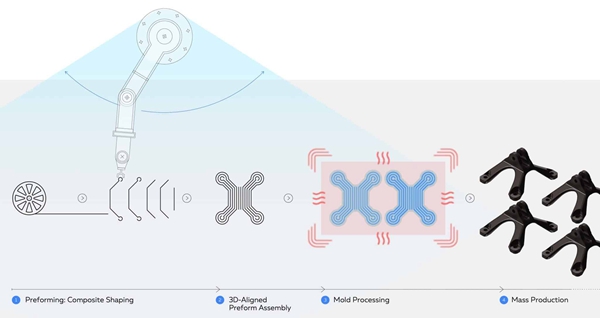

Founded in 2017, Arris Composites enables the volume production of lightweight, high-strength composite parts through its proprietary Additive Molding™ manufacturing technology. With this new process, advanced carbon fiber materials can be produced at the same speed as molded plastic products. To unlock customer potential, Arris has developed unique tools for internal application design and engineering collaboration teams. Customers can now design and produce previously impossible products that are highly integrated, stronger and lighter than metal.

ARRIS Additive Molding Technology Reaches Multi-Million Production Capacity

Additive molding is a manufacturing, materials and software technology pioneered by ARRIS, and its production capacity has increased from tens of thousands of parts in 2021 (Berkeley plant) to hundreds of thousands of parts in 2022 (Berkeley plants). Berkeley and Taiwan). Working with contract manufacturers in Malaysia, ARRIS expects the additive molding technology to reach initial production capacities of more than one million parts per year.

Riley Reese, CEO and co-founder of ARRIS, said: “The ARRIS team began entering the advanced composites market five years ago, and we have pioneered new technologies based on molding methods. traditional methods to deliver millions of pieces to the mass market. With our contract manufacturing partner establishing the production line, we have reached a major manufacturing milestone that will allow us to meet the needs of additive molding. We are only beginning to see the impact this technology will have on various industries.

ARRIS has also doubled its in-house material production capacity through February 2023 to support growing customer projects while continuing the research and development of bioresin and natural fiber material options. Additionally, ARRIS has made significant technological advancements that have helped customers accelerate project progress.

“The team achieved one of the fastest delivery times to date, producing the first products within 10 days of finalizing the design,” said Erick Davidson, principal engineer and co-founder of ARRIS . “Through our ongoing commitment to innovation and continuous improvement, we. The sophistication of the additive molding technology offered reaches new levels, allowing us to push the boundaries of composite materials like no one else. »

Today, brands in the wearable electronics, footwear, sporting goods, transportation, and industrial industries are leveraging additive molding to achieve unprecedented product performance differentiation and greater sustainability of their products.

ARRIS received the 2023 BIG Innovation Award in January and the 2022 LEAP (Leadership in Engineering Achievement Program) Award in December. ARRIS was also named one of Fast Company’s “10 Most Innovative Manufacturers” in 2021. Other honors include East Bay EDA’s 2021 Advanced Manufacturing Innovation Award, Business Intelligence Group’s BIG Innovation Award in 2021 and 2022, the 2021 GOOD DESIGN Award from the Chicago Athenaeum and the 2020 Design Concept Award from Red Dot.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.