2023Year4moon25That day, according to Mohou.com, NASA and a team of innovators from Ohio State University developed a technology calledGRX-810A new type of dispersion-strengthened superalloy, which is 3D A breakthrough in printing materials at high temperatures could create stronger, more durable parts for planes and spacecraft.

Black-smith and his Glenn colleague Christophe Kantzos jointly invented GRX-810High temperature alloy type. The research results were published in “Nature“In a peer-reviewed article published in the magazine, the title of the article is “A 3D printable alloy designed for extreme environments“. A team of participants from Glenn, NASA’s Ames Research Center in Silicon Valley, California, NASA’s Marshall Space Flight Center in Huntsville, Alabama, and Ohio State University co-authored the article.

Links to related articles:

The paper’s lead author, NASA’s Glenn Research Center in Cleveland,Tim Smith“This high-temperature alloy has the potential to significantly improve the strength and toughness of components used in aviation and space exploration,” said Dr.Black-smith and his team use time-saving computer modeling software and laser powder bed fusion 3D Print (LPBF) equipment to produce sample parts. They used this method to create the image below NASA logo.

△3D Macro photo printed by GRX-810 Made of oxide dispersion reinforcement (ODS) high temperature alloy

GRX-810It is an alloy reinforced by oxide dispersion. Its strengthening mechanism relies on the dispersion and distribution of tiny oxide particles within the alloy matrix, thereby improving the strength of the alloy. This alloy is ideal for making aerospace parts for high-temperature applications, such as those inside aircraft and rocket engines, because they can withstand harsher conditions before reaching their breaking point .

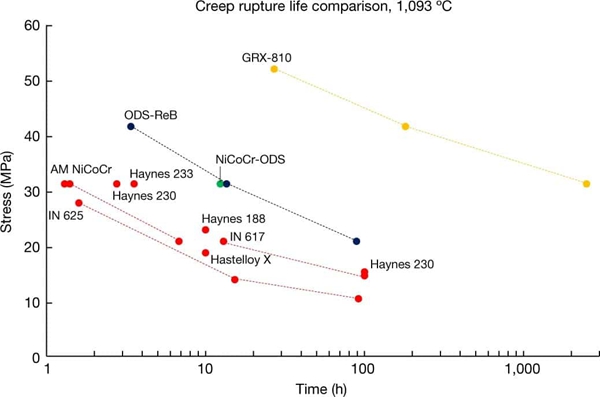

△1,093 °C Scatterplot of the creep fracture life of alloys at high temperatures. with currently used 3D Compared to wrought alloys for printing high temperature applications,GRX-810 Has excellent creep properties

The most advanced currently 3D Print high temperature alloys such asHaynes、Hastelloy And Inconelseries, can withstand up to 2,000 Temperature in degrees Fahrenheit. Compared to these,GRX-810 are twice as strong and durable as their 1,000 Lots more antioxidants.

Dale Hopkins, deputy director of NASA’s Transformational Tools and Technologies Program, said:“This new alloy constitutes a major success. In the near future it will probably become Glenn from NASA One of the most successful technology patents of all time. “exist 2019 Year,NASA It also supports a product called GRCop-42 The new material was developed by NASA’s Marshall Space Flight Center in Alabama, a high-strength, highly conductive copper-based alloy.MSFC) and NASA’s Glenn Research Center in Ohio (RCMP) created by a team.

△In GRCop-42 of VELO3D Thrust chamber in cross section printed on sapphire system. Chamber walls contain internal channels for regenerative cooling

GRX-810Copper alloys have been used by several companies, including the famous Bike3D) are widely used in additive manufacturing to produce almost fully dense particles. 3D Print parts such as combustion chamber liners and fuel injectors. The alloy was developed under NASA’s Transformational Tools and Technologies program, with support from the agency’s development programs.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.