BMW has always been committed to innovative technology and superior automotive manufacturing, and now, using3DPrinting technology became his new choice.

△ BMW uses3DNew patented technologies in demand in the field of printing technology are all reshaping the process of car bucket seats.

2023Year6moon16day,Mohou.com learned that,BMW (BMW) plans to develop an innovative solution3DPrinted bucket seats that lack traditional foam padding compared to existing car seats but still provide superior comfort. Currently, BMW has filed a patent application with the German Patent and Trademark Office. This technology is called “component additive manufacturing process”.

BMW plans to develop a3DPrint bucket seats

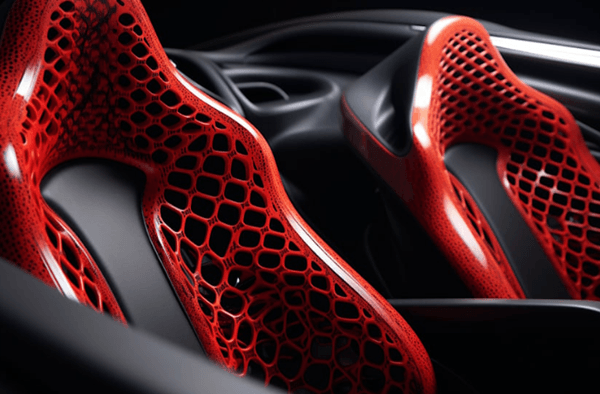

Additive manufacturing can also be called3DPrinting technology that uses materials of different densities arranged in specific ways and hardened in specific ways, making some elements stiffer than others, while others remain soft and flexible.

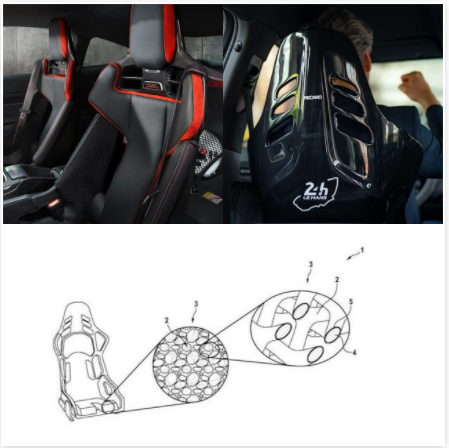

△The hollow shape that traditional seats can achieve

Take BMWM4 CSLBucket seats in cars, for example, have a central frame with a tightly structured mesh that is hardened so that it becomes rigid and provides the right support to adapt to different environments. But the outer layer of the seat is made of a looser lattice structure and is solidified in different ways to present a sponge-like structure to provide a comfortable driving experience.

△Example of traditional seats in BMW cars

While currently sport bucket seats typically use a carbon fiber shell and foam padding as a support system, or separate padded struts attached to the seat, BMW offers a new versatile seat construction. In theory, this looks like a simple“Bucket” with a smooth surface. However, different areas of its spongy outer layer deform to varying degrees due to different degrees of pressure, revealing different internal structures. The seats offer gentle support in all the right places, especially at the hips, and the extra padding will go a long way to improving occupant comfort.

△ Adopt3DPrinting technology could make car seats without fillers

The car seats of the future

Additionally, multipurpose seating has other benefits. For example, vehicle occupants are better supported at the base of the cushions and the seats are correctly accommodated regardless of body size and weight distribution. At the same time, the elasticity of the seat is also controlled. It is neither too hard nor too soft, which can meet the needs of different occupants. Especially for lighter occupants, who prefer softer support, while heavier drivers and passengers require firmer support. The multi-purpose seat will not show serious deformation after stable use and can maintain its support.

At the same time, versatile seating can also improve the health and safety of occupants. Seat stability can reduce harsh vibrations and rocking experienced by occupants during prolonged driving, reducing the risk of neck and lower back pain. At the same time, in an emergency, the multi-purpose seat can better protect vehicle occupants, keeping them in their seats in the event of a collision, reducing the risk of injury.

Looking to the future, the seat can also be customized according to individual preferences.3DPrinting technology offers a range of choices in colors, patterns, designs and textures. BMW also claims that this technology can also be used on armrests, steering wheels and dashboard decorative elements to create soft-touch elements without the negative environmental impact of foam.

BMW says traditional foam padding was once popular but no longer offers lasting benefits and is being replaced3DPrinting technology is more environmentally friendly and advanced.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.