Choosing the right device is always a complex task: before comprehensively evaluating existing solutions, you must clearly define your needs. Today we are going to look at the factors to consider when purchasing a portable 3D scanner. The particularity of a portable 3D scanner is its ability to scan objects in real time, without restrictions on physical size and with great freedom of movement: the device is capable of instantly capturing a large number of images to create a cloud of points. What you need to understand is that portable 3D scanners are divided into three series: scanners for manufacturers; scanners intended for professionals and industrial scanners; Another significant difference lies in the scanning process: some devices project structured light, while others rely on laser beams. Finally, a portable 3D scanner can be wired or wireless, in which case it can be more easily moved but has more limited battery life.

Why buy a portable 3D scanner?

Before we look at the options for handheld 3D scanners, let’s first look at the reasons to buy a 3D scanner. Contrary to popular belief, the scanning of an object is not always carried out with the aim of directly reproducing the object in question via 3D printing immediately after scanning. “The intention may be to design around digitized parts, in which case the digitized parts will form a working environment,” explains Benoit Michaut.

However, it is very rare to print something immediately after scanning: “A 3D scanner is not a copier, and do not assume that scanning a part can be used immediately. It always takes several hours of work to get a file that can be.” be used for manufacturing.

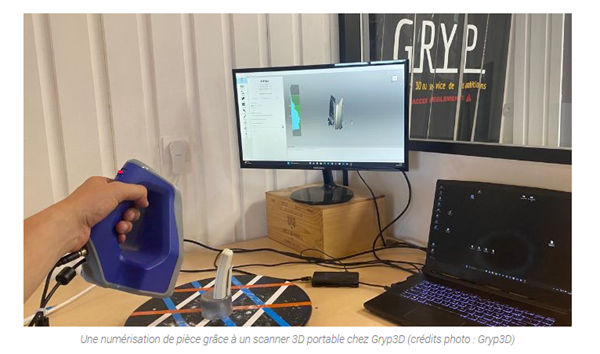

Most often, the scanned files serve as a basis for the design of objects with optimized properties. The design had to be adapted to the chosen rapid prototyping manufacturing process: “We rarely reproduce exactly the same geometry. If the parts had to be visually identical to the original to modify the car, the idea was to systematically adapt the design to the original. the manufacturing process. » The CEO of Gryp3D explains: “We define the process before we draw it, so we need to understand that if we simply scan the parts to copy them, we will not be able to improve the functional areas that are not visible. and therefore does not guarantee good mechanical resistance.

For Gauthier Laviron, digitizing parts saves time during the design process: “The scans are mainly used to restore original curves and complex surfaces in order to be able to project them on a screen and then redesign the part from that, he explains: “It makes you win.” we spend a lot of time reworking, which would tie up the machine and create a lot of CAD back and forth.

For Pascal-Peever, the goal of using a 3D scanner was to make the digital sculpture of the statue he created using Zbrush modeling software more precise. In fact, if sculpted solely using digital techniques, some curves and other subtleties will appear worse than when 3D scanning a real object.

So why use a portable 3D scanner? Our three experts agree: handheld 3D scanners are suitable for scanning objects of all sizes. “When you need to scan parts, wired scanners are more than sufficient, but when you need to scan the entire car or its interior, “wireless” works much better,” explains Gauthier Laviron. “Handheld 3D scanners can adapt to all users, needs and situations. They are available from most manufacturers. However, they are not suitable for scanning small and delicate parts: to obtain quality results, the object must measure at least 15 cm long,” said Benoît Michaut. Pascal-Peve explains: “I was very happy with the first scanner I bought, the EinScan SE from Shining3D, but the only limitation was the scanning volume: that’s why I bought the portable 3D scanner Einstar from the same manufacturer. Pascal Peiffer explains: “Besides the problem of scale, portable 3D scanners allow us to scan more complex parts, as well as to scan outdoors.

Choose a portable 3D scanner

There are tons of portable 3D scanners to choose from, so how do you find the one that’s best for you? Benoit Michaut says: “It is very important to be clear about your needs. To do this, you need to ask yourself a few questions, starting with the size and volume of the part to be scanned. The resolution required for rendering is also a basic criterion. criteria. It depends on the environment of use: Professional, occasional… but also on the way in which the file is used. Indeed, as mentioned above, if the goal of the scan is to reproduce it by 3D printing, then the scanning requires greater precision. Provide this level of precision. However, the need to capture color will also impact equipment choice. Machines based on structured light processes can capture color and texture, unlike 3D laser scanners. Of course, budget is also a factor. , so if necessary, the requirements may need to be reduced.

“I also take technical factors into account when choosing a portable 3D scanner. In particular, I prefer to avoid sticking mats on the elements to be scanned,” explains Gauthier Laviron. For the founders of Gryp3D, it was also important to find processing software compatible with the scanner of their choice. “In my mind, it has to be able to extract the data I need for a 3D design in the most comprehensive way possible and be easy to use so I can pass it on to anyone on my team “, he explains.

Pascal Peiffer chose the EinScan SE 3D scanner for its value for money and ease of use. He then chose an Einstar handheld 3D scanner because of its ability to handle large volumes and capture specific textures and colors, such as hair or dark materials.

With all these standards, how can you make sure everything is okay? “It’s best to first browse the retailer’s website to see what’s available and compare models. Once you’ve chosen a model, before purchasing, I recommend asking a professional to confirm your choice,” explained Benoit Michaut. The role of Atome3D in supporting and advising customers.

Other suggestions

Gauthier Laviron advises: Investing in a 3D scanner must be tested; the versatility of a scanner is rare, but it exists.

Pascal-Peever continues: Determine your budget, your volume and the level of precision required, then take the time to compare on sites and forums. You are almost guaranteed to find what you are looking for.

Benoit Michaut concludes: To facilitate the scanning of the pieces, do not hesitate to use mattifying sprays, in particular self-evaporating sprays like those from AESUB. Not only do these sprays make it easier to scan clear, reflective or black objects, they also improve scan quality by improving uniformity on opaque objects. Before you begin, you also need to make sure that your computer has the right configuration, namely a graphics card and enough RAM to store the point cloud provided by the scan.

source:3dnatives.com

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.