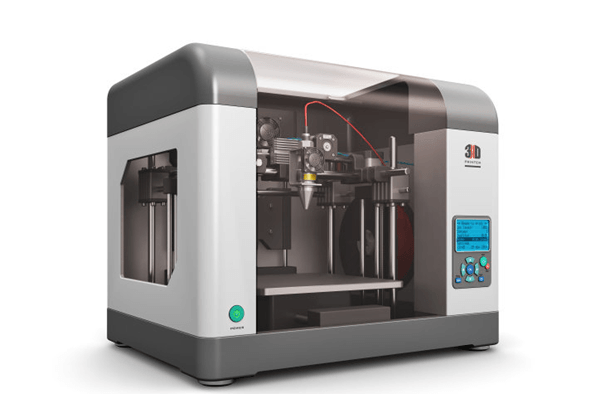

Introduction: any3DThe power supply is one of the most important and expensive parts of a printer. The power supply, located between the wall outlet (AC power) and the rest of the machine (usually DC power), forms the backbone of the entire electrical system inside the printer. However, not all parts of the printer are“Large energy consumer». So which parts of the machine require the most energy? In this article, Mohou.com will learn the secrets here with you!

heating element

The heating isFDMAn important component of a printer, the heating element is often the largest energy consumer in the entire system. In most printers, there are two main heating subsystems, namely:

●Extruder Heating: The extruder heating element is responsible for heating the hot end to the correct temperature to melt the filament. Maintaining proper temperature is crucial, as material that is too cold or too hot can cause a print to fail. Generally speaking, extruder heating elements are resistive elements on the ohmic scale. According to Ohm’s law(P=IV)Draw the power into12VStandard powered extruder heater can easily draw50Wpower above.

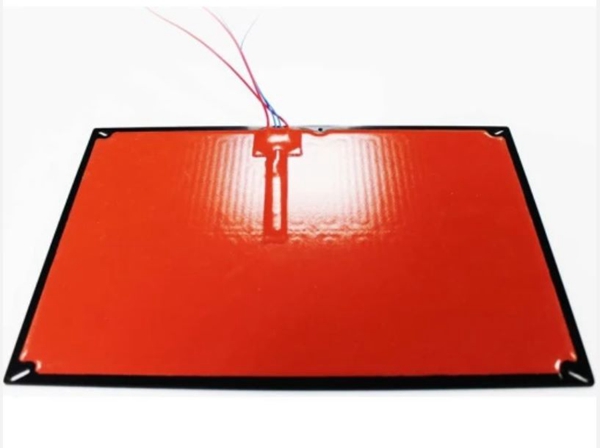

●Heated beds: numerousFDMThe printers are equipped with heated beds to ensure good adhesion of the first layer and minimize warping. These systems are also usually implemented with resistance heaters, e.g.PCBheater or silicone heater. Since the heated bed has a much larger surface area than the extruder, the heated bed generally requires more power to properly heat it to temperature.

△with silicon heating3DPrinter heated bed

Electric motors and mechanical components

In addition to heating,3DThe biggest energy consumers of a printer are generally the mechanical components:

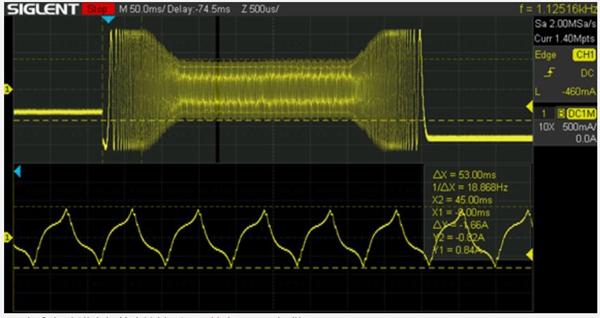

●Stepper Motor: Stepper motors in printers are used to control the movement of the extruder and build platform. Stepper motors require specialized drive circuits to convert electrical energy into magnetic energy and magnetic energy into kinetic energy of the motor. The power consumption of a stepper motor depends largely on the load it moves and the speed at which it moves. Therefore, the power consumption of the printer motor will depend on the operation of the motor and the mechanical structure of the machine.

●fan:3DPrinters use fans to move heat throughout the system, whether moving it away from the most recently extruded layer of material, circulating air into a heated chamber, or throughHEPAFilters filter out particles and fans are an important part of these systems. They usually use DC power and the supply voltage to the fans is often this high.24Vpower consumption can reach1Wor higher. Since they operate continuously during the printing process, they contribute significantly to overall power consumption.

△3DCurrent waveform of the printer stepper motor.

Electronics and controllers

The last thing to introduce concerns the electronic equipment inside the printer. Although most of the items discussed in this article are electronic devices, in this article,“electronic equipment»Refers to the processing, display, and control electronics within the system.

●Motherboard, processor and microcontroller: The motherboard, processor and microcontroller are used to manage all operations of the printer, including temperature control, motion and user interface. Although they do not consume as much energy as heaters or motors, they still contribute to overall energy consumption.

●Display and user interface: touch screen orLCD screenMonitors also consume power. Among them, the LCD backlight generally consumes the largest amount of power. The power consumption of the monitor is still very low compared to the rest of this article.

learn3D FDMThe dynamics of energy consumption within a printer can provide users with insight into how the machine uses energy. Overall, heating elements, motors, mechanical components, and electronics and controllers contribute greatly to overall energy consumption. Extruder heatsinks and heated beds make up the lion’s share, followed closely by stepper motors and fans. Although the power consumption of the motherboard, processor, microcontroller and display interface is not as critical as that of the above components, it is still an element of power consumption. As technology advances, balancing operational efficiency and energy consumption will continue to be a critical task for engineers and designers in the additive manufacturing industry.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.