When it comes to CNC machining complex parts, the process can be both mentally and physically challenging. It requires a deep understanding of the various tools and techniques involved, as well as a good deal of experience and knowledge. In this article, we will explore five essential tips for successful CNC machining of complex parts, drawing on the expertise of GreatLight CNC Machining, a leading provider of precision machining services.

Optimize Your Design

In order to achieve success in CNC machining complex parts, it is crucial to start with a well-designed part. This requires the use of Computer-Aided Design (CAD) software, which allows for the creation of detailed, accurate designs. By visualizing the part, you can identify potential problems and simplify complex features, reducing machining time and increasing accuracy.

In addition, a well-designed part can help to minimize the risk of unnecessary geometries, which can lead to increased machining time and costs. By streamlining the design process, you can ensure that your part is manufactured efficiently and effectively, resulting in a high-quality end product.

Select the Right Tools

The selection of the right cutting tools is critical to the success of any CNC machining operation. High-quality tools designed for specific materials and geometries can significantly impact precision and reduce wear and tear on equipment. This is because the right tools are optimized to work efficiently with the specific materials and production procedures used in your shop.

When selecting cutting tools, it is essential to consider the type of material being machined, the desired surface finish, and the level of precision required. By choosing the right tools, you can ensure that your parts are manufactured with precision and accuracy, resulting in a high-quality end product.

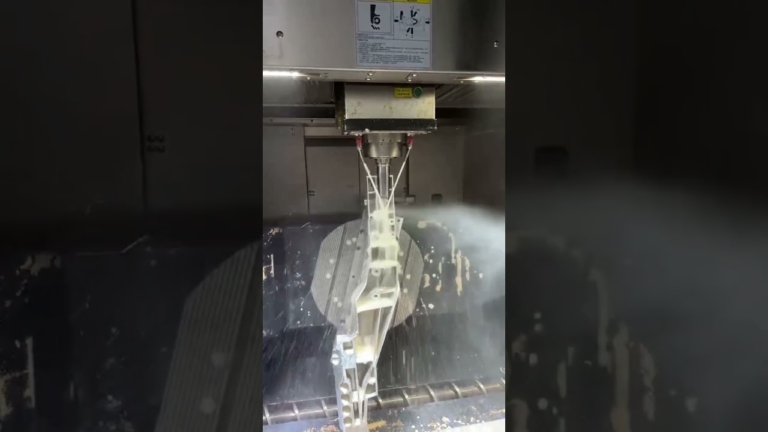

Leverage Advanced Equipment

In order to tackle complex geometries and tight tolerances, it is often necessary to use advanced equipment, such as 5-axis CNC machines. These machines offer increased flexibility and can significantly improve the accuracy and efficiency of your production process. By leveraging advanced equipment, you can ensure that your parts are manufactured with precision and accuracy, resulting in a high-quality end product.

Implement Rigorous Testing

Before proceeding with full-scale production, it is essential to conduct thorough testing and prototyping. This process allows you to identify potential problems and make adjustments to your machining strategy, ensuring that your parts meet the required specifications and tolerances. By implementing rigorous testing, you can minimize waste and guarantee a high-quality end product.

Focus on Quality Control

Finally, it is crucial to implement a strong quality control program at every stage of production. This includes inspecting and measuring each part to ensure that it meets the required specifications and tolerances. By implementing quality control measures, you can ensure that your parts are manufactured with precision and accuracy, resulting in a high-quality end product.

In conclusion, CNC machining complex parts requires a combination of precision, expertise, and attention to detail. By following these five essential tips, you can ensure that your parts are manufactured efficiently and effectively, resulting in a high-quality end product. At GreatLight CNC Machining, we pride ourselves on our ability to handle even the most complex machining projects, and we are confident that by following these tips, you can achieve similar success in your own machining operations.

For more information, please contact us at [email protected] or visit our website at glcncmachining.com.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.