As the global carbon neutrality process advances, the automotive industry“Low-carbon” development has become a general trend, and lightweighting is an important way to reduce carbon emissions from traditional fuel vehicles and new energy vehicles. Among them, lightweight materials and lightweight manufacturing processes are currently the most direct and efficient route. Among the many lightweight materials that can replace steel, aluminum alloys have obvious advantages over other materials, based on a comprehensive comparison of the three dimensions of weight reduction potential and manufacturing process.

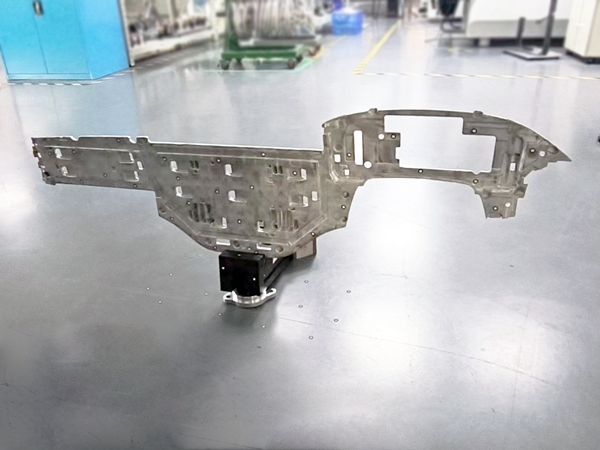

Aluminum alloy has good ductility and is suitable for various style designs. However, for this reason, automotive aluminum castings are also susceptible to deformation due to external forces or temperature changes during the manufacturing process, and detection of their deformation conditions is crucial.

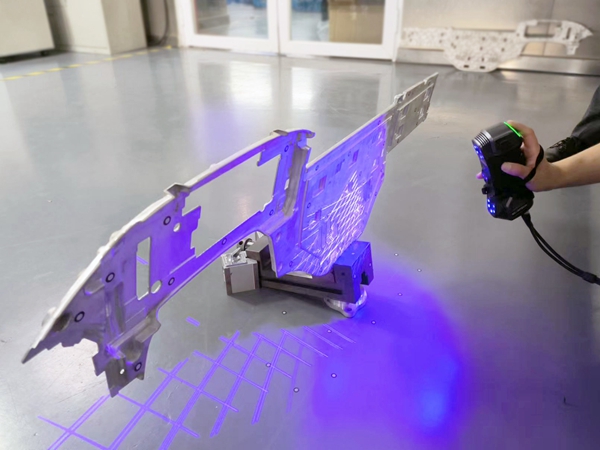

Use a handheld computer3DThe scanner can greatly simplify the inspection workflow and significantly improve inspection efficiency, which has been praised by manufacturers using this new type of inspection equipment.

Cast Aluminum Auto Parts3DTest plan

Customer testimonials

Highly efficient testing equipment, the efficiency improvement is obvious. Before, it took us almost a whole day to adjust a part of a product, now it only takes1It can be completed in about an hour.

Previously, only after adjusting one part of the product could another part be adjusted. Now, because the test equipment is more flexible and is not limited by the test site, it is possible to carry out the adjustment tasks of several parts of the product in parallel, which significantly optimizes our workflow .

Customer needs

This customer is deeply involved in the field of lightweight metal materials globally, and the products it develops and manufactures are widely used in automobile manufacturing,3CElectronics, aerospace and other fields to support the development of light industry in China and the world. Customers Use Sikan Technology Handheld3DThe scanner is mainly used to observe the deformation deviation of the product, and then make shaping adjustments according to the measured values.

Use equipment

SIMSCANStandard portable 3D scanners

Advantages of the solutions

Portable and flexible: lightweight body, unlimited measurement

Compared with the strict requirements of traditional measurement methods at test sites, portable3DScannerSIMSCANLight and compact, only heavy570gcan be integrated into different measurement scenarios, is not subject to site restrictions and can operate flexibly.

Doubled efficiency: task parallelism, process optimization

In the traditional solution, it takes more than half a day to measure the gap of the product parts, then heat treat and shape them according to the data, and then measure the shaped product parts. The overall time exceeds.1Days, and only after adjusting one part of the product, another part can be adjusted, which is not very efficient.

SIMSCANPortable3DThe introduction of scanners has brought great efficiency improvements to customers. I just need3 minutesThat’s it1Scanning measurement of individual parts of the product (as shown in the figure).

In addition, its portability provides the possibility of flexible transitions during measurement, helping to optimize the inspection process, and can realize the tasks of scanning measurement and heat treatment shaping adjustment of multiple parts of the produced in parallel without conflicting with each other.

Complete data: from point detection to global detection

Compared with similar products,SIMSCANThe camera is closer, making it easier to scan small spaces. Thanks to this advantage, even data located in hidden places such as grooves and flow channels can beSIMSCANcan be captured effectively.

The traditional solution only measures certain points and cannot obtain the changes and trends of deviations in the whole region. to useSIMSCANIt can collect its complete and comprehensive three-dimensional data and successfully upgrade product measurement and inspection from single-point inspection to whole-area inspection.

Results are intuitive: visual reports are easy to read

SIMSCANPortable3DThe scanner cooperates with a system that integrates scanning and detection3DsoftwareScanViewergenerated in real time3DModel. Compare it with digital analog to quickly get an intuitive, easy-to-read test report, so that subsequent heat treatment and shaping of the product can be evidence-based.

After heat treatment and shaping, the product parts are measured again and a detailed test report is obtained:

Suitable for beginners: easy to use, quick to learn

Compared to traditional, portable detection solutions3DThe operation of the scanner is simple and easy to learn. Powered by Sikan Technology3Dscanning1V1Engineer training services help end users get started quickly, while lowering the threshold for hiring inspection personnel, effectively reducing labor costs for businesses.

Benefiting from the accelerated penetration of new energy vehicles and the rapid growth of the amount of aluminum used in individual vehicles under the lightweight trend, it is reported that2023Within a year, the amount of aluminum used in China’s automobile industry will reach889.3million tons, the market size of the automotive aluminum foundry industry is expected to reach6651.8billion, the average compound annual growth rate will exceed20%。Note: Data source: Essence Securities

Facing the good market outlook, the introduction of high-quality products3DScanning measurement solutions will help lightweight metal materials companies further transform and modernize in this high-growth, high-quality sector. In the future, Sikan Technology will continue to be committed to providing comprehensive integrated solutions for the automobile manufacturing field.3DDigital solutions help companies stand out in the highly competitive automotive manufacturing market.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.