Introduction: Replacing critical parts and purchasing casting parts often consumes a lot of labor and material resources, mainly due to the need to wait for traditional models or core boxes. It is often not cost effective to purchase expensive tools machined from wood or metal for small batches or one-off castings. However, the most critical castings, often used in infrastructure or transportation applications, are in high demand and supply chain delays are increasingly common. Disruptive technologies are driving the growth of next-generation metal castings.

△Reduce supply chain risks by using sand binder jetting to produce molds and casting cores directly from digital models, significantly reducing lead times, tool investments and defects casting.

Digital sand casting using binder jet 3D printing eliminates the high costs and months-long lead times of traditional casting tools. The 3D sand printing process uses digital data to print molds and cores in sand directly from CAD files instead of tools. No need to wait to create new models or repair core boxes, no need to create new tools and large upfront costs. Like producers in other industrial sectors, foundries benefit from integrating 3D printing to solve supply chain challenges and improve operational efficiencies by providing rapid castings of replacement parts while by exceeding customer expectations.

On-demand tools enable decentralized production, a solution that helps reduce supply chain risks.

3D sand printing has been used in foundries to create metal casting tools for more than two decades, and today’s binder jetting systems can produce precision molds and cores with batch production. Industrial printheads selectively deposit adhesive into a bed of sand particles, forming thin solid sections, one layer at a time, similar to printing on paper.

●ExOne is committed to helping quantify the need for 3D sand printing technology to develop methods of supplying rapid replacement metal castings. In collaboration with various partners, we are working to develop relevant thresholds to establish a method for determining when it is efficient and economical to source castings made from digital molds and cores.

●The benefits of 3D printing can also be leveraged to improve the quality of hard-to-obtain components that often suffer from quality and consistency issues during the casting process. Using binder jetting to create patterns provides design freedom that enables innovation in casting tools, creating complex, consolidated geometries that enable lightweighting and optimized part performance that is not previously possible. not possible with traditional processes.

●The design freedom of additive manufacturing offers benefits such as the integration of scrap-reducing cores or organic assembly capabilities that facilitate smooth first pours to quickly bring critical precision castings into service.

Replace obsolete parts within two weeks – 3D printing comes to the rescue

Marine engines operate in harsh environments and are frequently exposed to moisture and water (often salt water), which can degrade engine components. Since diesel engines produce combustion through high pressure and heat in the cylinders, they must operate at high compression ratios to generate enough heat to automatically ignite the diesel fuel. The cylinder head is a critical component of your engine, supporting other important components such as fuel injectors and intake and exhaust valves. Located on top of the cylinder liner flange and attached to the cylinder block with nuts and bolts, they are exposed to extremely high temperatures and pressures, expanding and contracting as the engine heats and cools quickly. Due to these environmental conditions, marine diesel engines must be able to withstand extreme pressures coupled with high cooling requirements.

Thai shipyard Hi-Tech Marine Engineering faced a problem with cylinder heads cracking due to massive stresses caused by overheating. Operational every day of the week, the freighter needed rapid repairs to return to service, but the damaged parts were almost ten years old and no longer produced by the OEM supplier. “Delivery times are critical to our business – we can’t wait for parts as we operate constantly, so we need a quick turnaround within budget,” said Aomthep CheinSuwan, owner of HiTech Marine.

Traditional spare parts have delivery times of more than 10 months and very high investment costs. Since the cylinder head is a conventional no-tool part, a completely new set of templates and core boxes must first be made before the replacement casting can be produced. However, Hi-Tec Marine requires replacement parts within 4 weeks, and any overseas orders will take at least 8 weeks, with additional shipping costs.

Speed 3D Mold is a Thailand-based molding and prototyping workshop whose solution is to provide high-quality spare parts in a timely manner. Nattinee Valun-araya, Director of Engineering at Speed 3D Mold, said: “For our customers in the marine industry, many old parts need to be replaced, and speed is the most important factor to prompt maintenance to keep the system functioning properly.

△Traditional replacement castings require a delivery time of 10 months, but those produced by 3D sand printing can be delivered within weeks.

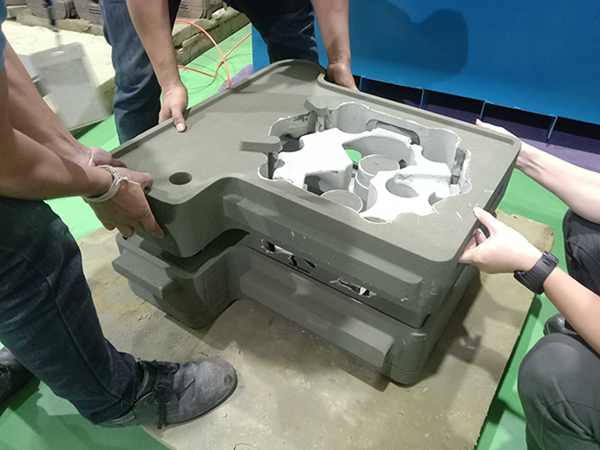

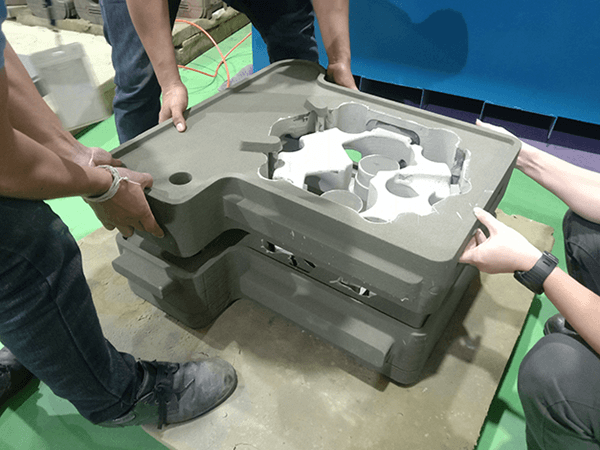

Speed 3D Mold’s engineering department has over a decade of experience in providing casting simulation support, 3D sand printing and prototype and replacement castings to provide services of reverse engineering at Hi-Tech Marine. The team 3D scans original parts to create digital CAD files that can be used to develop 3D printed molds and base packaging for molding new components. With binder jet 3D printing, no hard tools are needed to create replacement castings, but molds and cores are built layer by layer in sand directly from a CAD file.

Using digital molding, Speed 3D Mold is also able to quickly iterate on parts to ensure the highest quality for Hi-Tech Marine’s replacement cylinder heads. The part contains many complex features, including large thickness differences and small cooling channels, but can be easily modified through a digital molding process. The design freedom of additive manufacturing also allows Speed 3D Mold to update cooling channel designs and freely place mounting systems in the mold without the constraints of traditional molding designs.

The complex 725 x 630 x 572mm mold set contains 19 3D parts printed in just 10 hours on an S-Max binder jetting system, in any size or shape. The nearly 100 kg replacement cylinder head is made of gray cast iron and the final component was delivered to Hi-Tech Marine in just two weeks. The huge capital investment required to make a mold for a single replacement part is not economical, but Speed 3D Mold’s solution using ExOne Sand Binder Jetting to directly print mold packages allows to save 40% compared to traditional production.。

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.