Click to learn more about flame retardant 3D printing materials from Mohou.com: flame retardant ABS, flame retardant ultem

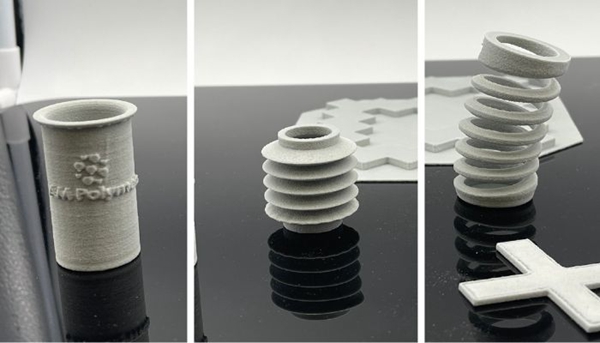

In recent years, the additive manufacturing of powdered polymers has received increasing attention from manufacturers.AM polymersThe company is a typical representative. The company has become a recognized partner and manufacturer in the polyethylene, polypropylene, polyamide, polyurethane and polybutylene terephthalate industries.

existSmartTech AnalysisA study published this year on the use of polymers in the automotive industry has once again strongly highlighted the possibilities and advantages of additive manufacturing materials. It should be noted that regarding the production of internal combustion engines which will be discontinued in the future, it is expected that2030By 2020, major automakers will increase the number of parts produced from polymers150Ten thousand increased to approx.600Ten thousand3DPrint parts. This means that target areas of the automotive industry, such as end-use parts, auxiliary production equipment such as fasteners, specific tools or assembly aids, will be more widely manufactured from polymers. This will result in material sales in this area from2022annual8000million dollars increased to2030annual6billion dollars. However, the list of applications for polymer powders is long. For example, you can find them applied to the top of firefighters’ foam nozzles, where geometry-matched structures can improve performance – using polypropylene./Polybutylene terephthalate. In other aspects of the fire protection field, polybutylene terephthalate can also be used to produce electronic enclosures for fire trucks.

△PA12Recycled powderROLASERIT® PA12-04RGR001Have andPA12Virtually identical mechanical properties and refresh rate to virgin powder for sustainable part production (Image source:AMPolymer Company)

AM polymersAdvantages of polymer powders

Additive manufacturing is known to have many sustainability benefits. However, the importance of materials cannot be underestimated. Especially in recent months,AM polymersThe company team isPA12great success in terms of recyclability. Thanks to a particular improvement, it can be reused with a refresh rate of50%without having to add new powder. By using this polyamide powder (available in black and white), the end result3DThe printed parts are of excellent quality, with no trace of reused materials. However, the benefits of this approach are not limited to increased sustainability, as users can also gain significant benefits in terms of profitability. For example, ifPA12of50%The refresh rate ofTPUof10%The refresh rate is compared directly and then withPA12compared to,20Size in liter can be determined43%profitability,72The size in liters can be up to96%. Another user experience benefit with additive manufacturing design (DfAM)related. Whether rapid prototyping, molds, production aids or even serial parts—If you specifically consider subsequent designs using powder-based additive manufacturing processes, you will find that in addition to the cost benefits,3DThe performance of printed parts can also benefit. Many users cannot directly identify the advantage of powder-based polymers in post-processing. Powder removal is an essential processing step after which the parts have a notable quality thanks to the use of polymer powder. In recent years,AM polymersCompany andAMTand those specialized in post-processingLuxYourWorking closely with the company, we found that after steam straightening,3DPrinted parts are not only visually identical to injection molded parts, but also have unique properties such as transparency or gloss.

△Polyurethane powderROLASERIT® TPU01NIRAllows the production of flexible, light-colored parts, therefore dyeable (Image source:AMPE)

In our general understanding3DOnce polymer powder printing can improve business efficiency, material innovation should also be looked at specifically. Besides the well-known injection polymer materials, the importance of flame retardant materials cannot be ignored. SO,AM polymers Materials extremely resistant to open flames have been specially studied. It should be noted that this involves aROLASERIT® TPU01FR of TPU powder, which will be released this yearNext formSales start at the show. all familiar TPU Anyone who handles powders knows that the material can produce harmful fumes and can even be broken down by lasers. but ROLASERIT® TPU01FR This is not the case, which is a big advantage, especially for companies focused on machine building capacity. Actually,ROLASERIT® TPU01FR Powders do not create flames, unlike standardized materials, meaning they are safer to use. In addition, this thermoplastic polyurethane, which has almost no aging effect, stands out from others TPU Compared to powder, it has greater fluidity and in terms of processing,AM PolymersROLASERIT® The products also make this task easier.

What benefits will polymer materials bring in the future??

Apart fromTPU01FR,AMPolymerswill be2023Three more flame-retardant polymer powders were launched earlier this year (PP01FR、PBT01FRAndPA11-01FR). All these powder materials are not only halogen free but also comply withUNECE R118.03,appendix7And8Fire safety standards. Additionally, fire safety standards will be implemented next yearUL94Further tests are carried out and additional tests are carried out so that they can be used in various fields. All of these materials are intended for volume use in the secondary market.

△Direct comparison: standard plastic (left) and flame retardantTPU01FR(RIGHT)

Of the 2021 At the beginning of the year,AMPolymers Take it PBT And PA11 The market is enriched with reinforced carbon fiber variants. This composite polymer can be used in traditional injection molding markets where parts require higher temperatures and mechanical strength. Especially after passing 3D When printing production end-use applications,AM polymers of PA6、PP And PA12 Carbon fiber powder offers up to 7300 MPa The extremely high rigidity therefore strongly limits the deformation of these materials.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.