Introduction: Generative design (generative design) is a computer and AI Driven design process that automatically creates products based on user-defined needs and constraints. Or, in simple terms, software designs parts or products based on product attributes and design goals proposed by the user.3DPrinting has many benefits in manufacturing generatively designed parts.

The more variables the generative design software contains, such as intended use, manufacturing methods, available materials, etc., the better the results generated by the computational design will be. Products designed via software usually have a curved appearance and a structure similar to tree branches or bones. Generative design has been likened to the evolutionary process of trial and error that nature goes through to arrive at optimal structures, but much more quickly. Using generative design has many advantages, such as saving materials while ensuring high strength.

△Use Dassault Systèmes of CATIA The software optimizes base support through generative design to save material and maintain strength (Source:Dassault Systèmes)

As shown in the image above, the right bracket is the original model. The left support is a section optimized to use less material while maintaining the same strength and respecting the same dimensions. The final stent can be injection molded, machined or 3D Print. Designs generated by artificial intelligence are often so complex that they cannot be 3D Made by printing method.

As powerful as generative design is, it will not replace designers or engineers. Generative design software is simply the tool they use to speed up design and optimize parts.AI It can produce a variety of results, compare the differences between different results, and find the optimal solution, which is difficult for designers to achieve in a short time.

Many software products have generative design capabilities that use algorithms to translate part requirements into product geometry and design. However, instead of generating dozens or hundreds of options, they improve a single part (which is a lot like parametric design). The two concepts are similar, but generative design is often associated with multiple design options rather than multiple iterations.

Generative design software

Shape optimization algorithms, or topology optimization, have long tackled one of the most fundamental engineering problems: how to make a part strong enough using as little material as possible. Today AI Generative design goes even further and offers a multitude of options. The important point is that engineers are no longer limited by their skill level, experience or creativity. At the end of a generative design analysis, engineers will have a concept that can be explored and refined further, or a ready-to-manufacture design solution that fully meets all project requirements such as weight , load, materials, etc.

△Automatic office of Fusion360 The software allows engineers to optimize components to reduce material usage and maximize functionality (Source:Autodesk)

Generative design is a creative tool that, like many other computer-assisted processes, requires a human to operate it. Success is therefore linked to the quality of the data entered by the user. Here we can borrow concepts from computer scienceCONVERTIBLE(”garbage in, garbage out“), incorrect input data can produce erroneous results. Although generative design tools allow almost anyone to master complex designs, do not underestimate the skills required to correctly define the initial conditions of the desired part In general, generative design software needs information to solve the problem includes:

●Physical constraints on the design space, including each interface of the new part in the larger assembly (such as mounting holes) and space that the new part cannot occupy. Generative design is often used to redesign parts so that they take up less space.

● Boundary conditions for forces and loads, including areas that must be strengthened or simplified to resist motion or operating stresses.

● Setting standards or goals, such as minimizing the mass or cost of a part and defining the safety factor required for the project.

●Feasibility of the manufacturing process, which is3DBenefits of printing and manufacturing,3DPrinting itself is extremely flexible, making it ideal for making generative design parts.

●Manufacturing materials. If more than one material is selected, a different design solution will be provided for each material to meet the project requirements.

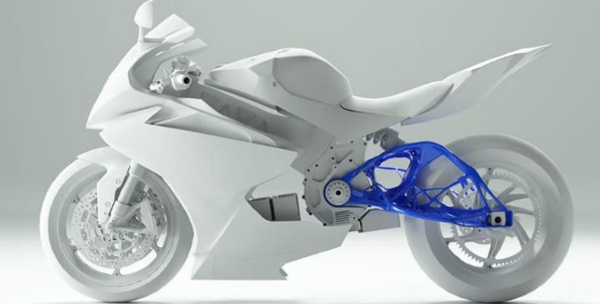

△Motorcycle rear axle optimized thanks to generative design (Source:Autodesk)

With all of these initial inputs (and many more options), the generative design tool can work its magic. It is common to start from a generic non-optimized design and analyze the stress distribution within it. The software then begins its iterative creation process, adding material in high-stress areas, subtracting material in low-stress areas, and re-examining the overall stress distribution. It repeats these steps until the predefined criteria are met.

Successful generative design research will result in a variety of design solutions. It is time for human professionals to step in again and choose one or more solutions based on their own criteria and experiences. Generative design software can also help users choose between different data visualization features to compare solutions. It should be noted that generative design does not guarantee that it will become the optimal solution. Sometimes the requirements of a project are too demanding and the algorithm cannot provide possible solutions. If this is the case, the user must adjust the criteria, constraints or materials and restart the study.

What are the advantages of generative design?

△Benefits include better performance, reduced costs and part consolidation (Source:Software for digital industries Siemens)

Now that we understand what generative design really is and what it can do, let’s identify the practical benefits of applying these tools in part manufacturing:

●Creativity. Generative design removes all limits to creativity associated with traditional design processes, creating the best unconventional shapes humans can imagine.

●Balance priorities. It can explore solutions based on performance aspects and manufacturing capabilities already available at a given site.

●Reduce analysis. Built-in test and calculation simulations reduce additional and costly computer-aided virtual engineering. (CAE) analyze.

●Reduce workload. It frees professionals from tedious trial-and-error tasks and increases productivity by providing hundreds of feasible design solutions.

●Reduce human errors. By automating much of the design process, the risk of introducing human error into the design is reduced.

●Reduce costs. Money is saved by delivering high-performance designs using fewer materials and reducing development and time-to-market time.

●Partial merger. Particularly when using additive manufacturing processes, engineers can explore the possibilities of consolidating parts and replacing entire assemblies with a single part. This can have a positive economic impact on supply chains and maintenance programs.

Algorithms and aesthetics: the future of generative design

△Ayoub Ahmad For 3D Digital rendering of a supercar designed for printing (Source:Ayoub Ahmad)

As the Internet of Things and artificial intelligence become more prevalent in our daily lives, generative design could become the norm in product design. This technology offers designs that will not only have a positive impact on the industry, but also on the environment, because less. resources will be needed to produce daily products. At present, derivative software is also developing rapidly, including Fusion360、Creo Generative Design Extension、Ansys Discovery、nTopology、Dassault Systèmes CATIA Generative Design Engineering wait. You can use these software and combine3DThe printing process creates your own generative design pieces.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.