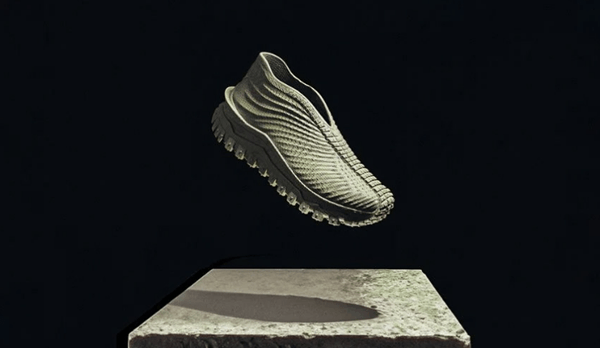

2023Year7moon19That day, Mohou.com learned that,as 3D Pioneer of printed shoes, ZellerfeldWith a luxury fashion brand known for its commitment to innovation Moncler cooperate. This partnership marks the brand’s foray into 3D In the field of printing, using a single recyclable material to create unique and durable shoes——Trailgrip 3D Sneakers. In fact, Zellerfield developed a technique that allows shoes to be taken apart and recreated using nets. There are no seams or glue, ensuring that the shoes can be recycled and reused. This is entirely consistent with Moncler Its commitment to sustainable development makes it an ideal partner.

Trailgrip 3DSneakers designed byMonclerMade with a futuristic design on the upper. The collaboration will take place at the brand’s interactive show in Paris. Studio Ascenti will be announced exclusively on Moncler Open to members of the global footwear community. This limited edition offers an exclusive glimpse into the future of innovative design from this luxury brand.

Zellerfeld And Moncler spear Trailgrip 3D shoe

This partnership marks a major change for the footwear industry,Moncler Other luxury fashion brands will do it 3D The print production model is considered the new standard. By breaking the traditional factory manufacturing process,Moncler are shaping the future of fashion and redefining what’s possible in sneaker design.

Observe carefully Trailgrip 3D shoes, we can observe 3D What a printer’s printout of a melted candle looks like. The same materials are used throughout the shoe, including hardened wax cores and sponge material, showcasing Zellerfeld Seamless integration enabled by technology.

The shoe is made from a single recyclable material

Zellerfeld exist 3D Expertise in printing and Moncler A glimpse of new manufacturing possibilities combined to create a revolutionary sneaker. The entire shoe is made from a single recyclable material, setting a new standard in shoe sustainability. While other brands explore specific components 3D When printing,Zellerfeld pushes the boundaries by using this innovative technology to create a complete pair of shoes.

source:3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.