Recently, Mohou.com learned thatIsrael Institute of TechnologyBeni Cukurel Team led by Assoc. (AM)Micro gas turbines have been designed, taking a giant step towards the future of power generation and propulsion. This revolutionary development greatly challenges traditional manufacturing methods.

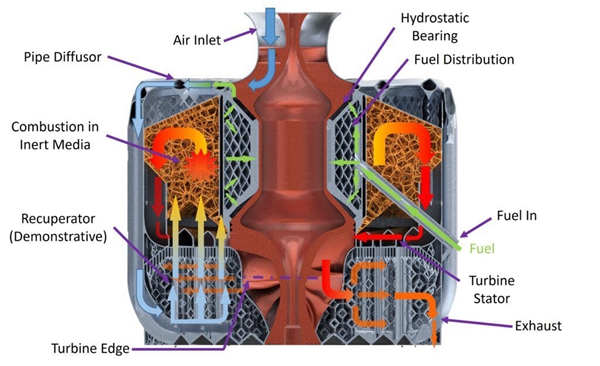

△Additive manufacturing of pre-assembled micro turbojet

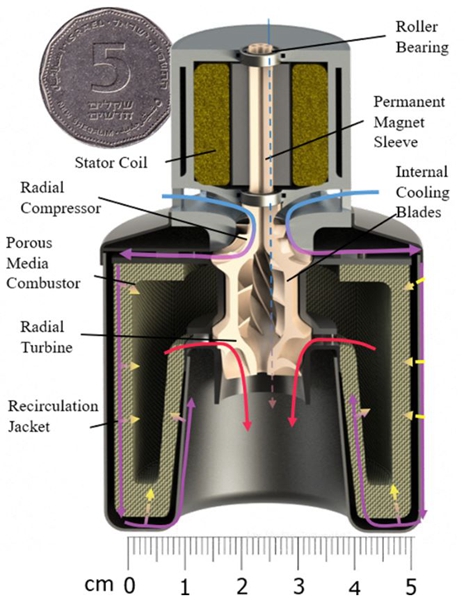

Cukurel The team and the Turbomachines and Thermal Transfers Laboratory are exploring the potential of additive manufacturing. Rather than simply using additive manufacturing as an alternative tool, the team viewed it as an essential resource, creating a priori designs to meet constraints and leverage the benefits of additive manufacturing. Microgas turbines, designed for high-efficiency electricity production, are at the heart of their research.Cukurel Gas microturbines are defined as those capable of producing 300 Electricity below kilowatts and 2 Systems with thrust less than kilonewtons. Using additive manufacturing methods, the team embarked on their first project, manufacturing a5Centimeter gas microturbine to power drones 300 Watts of electricity. Microturbines have a higher energy density than conventional batteries and can therefore significantly increase flight times.

△Gas and fuel paths

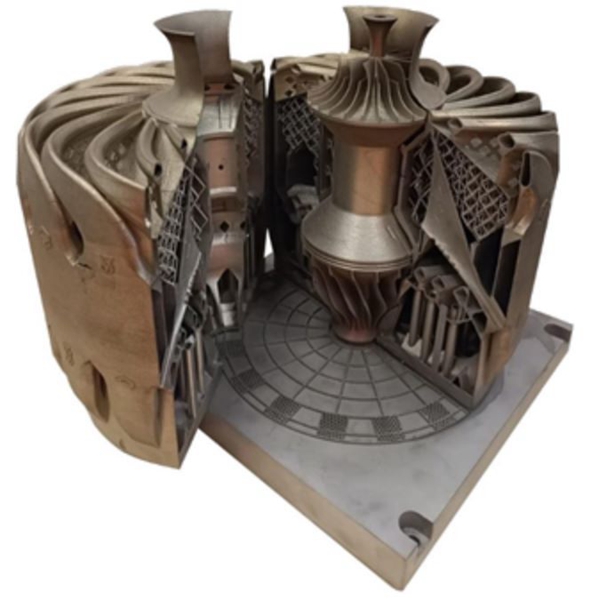

The team didn’t stop at microgas turbines; COVID-19 Additive manufacturing knowledge was leveraged during the crisis to further innovate the design of pre-assembled, self-supporting turbomachines for medical ventilators, successfully transferring the know-how developed in pre-assembled self-supporting turbomachine structures to turbines with gas. These pre-assembled, self-supporting gas turbines have lower costs, with the main costs consisting of machine time and power consumption only, thereby significantly reducing production expenses.

Cukurel He said that carrying out such innovative works is inseparable from cooperation with Von Kármán Institute of Fluid Dynamics, Izmir Katip Serabi University andCTPcooperation. In this NATO-funded project, each party demonstrated its unique expertise, with the Von Kármán Institute providing high-fidelity simulations of aerodynamics and combustion and Katip Serabi University in Izmir using computational fluid dynamics to evaluate the load capacity of hydrostatic bearings,CTP Provides in-depth knowledge of additive manufacturing technology, specifically utilizing its powerful GUJATDesign and simulation models.

△Self-supporting rotor (turbocharger) and surrounding fixed self-supporting shell (regenerator, nozzle guide vanes, bearing box, burner, diffuser).

Optimizing performance with additive manufacturing

Cukurel explained that to address the limitations of additive manufacturing designs, they first developed reduced-order models. Simply put, it is an optimized model that retains key elements of the original system but simplifies it for analysis and use.

Traditionally, when designing jet engines, aerodynamics has been primarily used, with the aim of achieving optimal performance in terms of thermodynamics, which translates into thrust-to-weight ratio and fuel consumption rate. , i.e. power and energy density. However, this approach fails when dealing with small engines.Cukurel Explains: “What we create is a reduced order model that captures all the factors that affect the engine, including aerodynamics, heat transfer, rotor dynamics and combustion. Think of it as a condensed symphony in a solo performance – you must preserve the essence of the work while adapting to the abilities of the soloist.

Cukurel Continuing to detail how to create a multidisciplinary optimization environment that understands a priori all the limits of additive manufacturing, they design a system that grasps the limits of creation from the start, a bit like an experienced architect who knows not to design roofs with angles that are too steep for the building materials to support, ensure that each layer built during the manufacturing process is self-supporting while meeting the constraints of additive manufacturing, which include considerations such as cantilever angles, minimum thickness and porosity.

In terms of materials,CukurelTo expressEOS M290Printing system for manufacturing metal parts, usingLithosof printers to create ceramic structures. Although ceramic components are more difficult to manufacture, there are some advantages to using ceramic as a material for some components, including smaller defect sizes and smoother surfaces, which improve aerodynamics and thus help reduce fuel consumption.

Cukurel stressed the importance of realizing the conceptual design and emphasized that as long as5%The deviation will impact fuel economy or thrust. In the world of jet engine design, even small percentage points can result in significant changes, and compressor performance with ceramic components improves aerodynamics by three to four percentage points.

△The overall additively manufactured silicon nitride rotor of the ultra-micro gas turbine is designed to operate at a speed of 500,000 rpm。

The future of energy is 3D Printed?

Israeli researchers use 3D Printing technology to pre-assemble motors could reshape the future of energy. Their projects, focused on the application of microgas turbines in distributed energy production, are changing traditional conceptions of energy efficiency and creating new possibilities for sustainable development.

Cukurel Two different applications are proposed for this technology:

●First, it emphasized military uses, including unmanned aerial systems. Supply chain disruption is a significant issue in this area, as it can leave critical operations without critical components such as bearings for six to nine months. Pre-assembled engine technology solves this problem by completely eliminating the need for such a supply chain.

●The second application is distributed energy production. The energy efficiency of conventional centralized power plants is capped at around 65%product35%energy is wasted. for this purpose,Cukurel A solution using distributed microgas turbines for cogeneration of heat and power at different locations is proposed.

△5Centimeter-scale ultra-micro gas turbine designed to generate300watts of power

CukurelExplains: “Renewable energy is a disruptive energy source. You don’t want to depend on whether there is wind today, do you? Otherwise, there will be sun today. You want to keep your factory running no matter what. So where is renewable energy? Disruptor, “How to have a flexible and robust network” In this case, flexibility refers to the ability to adapt and respond. rapidly to changes in energy demand, and these changes are the unpredictable production of renewable energy.

Although the transformative potential of this technology is clear, the main obstacle currently faced is return on investment. The cost of microgas turbines is too high to produce a satisfactory return on investment within a reasonable time frame. Currently, the researchers are also considering commercializing their work, and collaborations with industrial players and strategic investors are also in the works.CukurelExpressed excitement about the potential social impact of the work, particularly regarding the microgas turbine’s ability to burn ammonia.

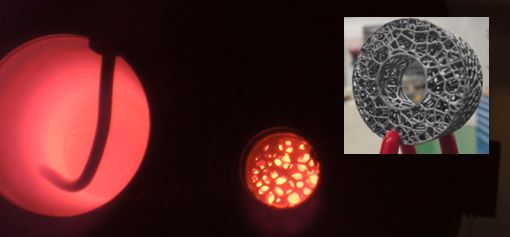

△Porous media burner with silicon carbide as fuel/Air ratio provides great stability

Sustainable energy using ammonia engines

Ammonia can be used as a renewable, green and carbon-free fuel. Ammonia has been used as a fuel before, notably during World War II in Belgium, but the design of gas turbine combustion chambers has since undergone significant changes. Wartime ammonia-fueled engines presented a number of challenges, primarily their fuel sensitivity and general lack of flexibility.Cukurel and his team have developed a technology, the porous media burner, particularly suited to the combustion of ammonia.

Cukurel “In gas turbines, most combustor designs use completely different technologies. They optimize the vaporization process, then use dilution tubes to meter the fuel and introduce the hot gases into the turbine,” explains the one of the innovations of the Technion-Israel Institute of Technology. The team lies in the unique application of a specific technology: porous media burners. This is the first time it has been applied to a microgas turbine burning ammonia, and its work is revolutionary.

let’s find outThe mystery behind the term “porous media burner”, it is a special type of burner, fuel–The air mixture is burned in a porous medium, producing efficient, low-emission combustion. Porous media burners have been around for at least 50 In 2006, the traditional manufacturing method involved dipping the foam in ceramic paste and then sintering it. However, asCukurelAs noted, there is no way to control porosity and how it is distributed in the flow direction. In order to solve the above problems, researchers used additive manufacturing technology to create a donut-shaped burner with a bubble-shaped organic network structure inside. The porosity of this structure changes in the direction of flow.3DThis is where printing comes into play because it allows control of porosity gradients that are not possible with traditional manufacturing techniques.

△Use premixed fuel/Porous media burner operating with air mixture

Cukurel Also co-author of a recently published paper using photolithography-based ceramic fabrication (LCM) and selective laser fusion (SLM) The technology provides comprehensive analysis of the design, production, assembly and high-speed testing of the integrated rotor. The study is titled “Ceramic and metallic additive manufacturing of monolithic sialon and Inconel rotors and comparison of aerodynamic performances for microturbines at 300W scaleis the first study to directly compare microturbomachine components using aerodynamic and manufacturing quality assurance diagnostics, examine the aerodynamic effects of unsupported compressor and turbine designs, and develop LCM And GDT of detailed manufacturing factors and process parameters, and by area andCTScan the parts for quality analysis, andWHICHPhotomicrograph. The results show that with GDT Compared to the rotor,LCM The rotor features greater geometric accuracy, better surface finish, fewer manufacturing surface artifacts, and lower porosity.

These revolutionary concepts and their future applications have the potential to change the world, and as we face the existential threat of climate change, such innovations could be essential to human survival.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.