Global consumption of fish, whether from fishing or aquaculture, often has significant environmental impacts. However, demand for this product shows no signs of slowing down. According to the Food and Agriculture Organization of the United Nations(FAO) estimates that by 2050, the planet will consume 140 million tonnes of fish. Faced with this growing demand, researchers and companies are turning to innovative solutions, such as 3D printed fish substitutes. Recently, a Chinese team took a new step and successfully 3D printed plant-based fabrics imitating yellow croaker meat.

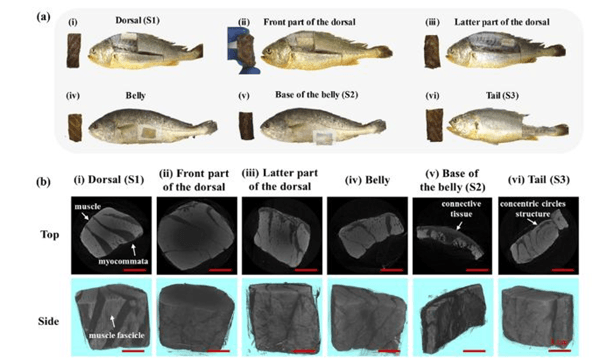

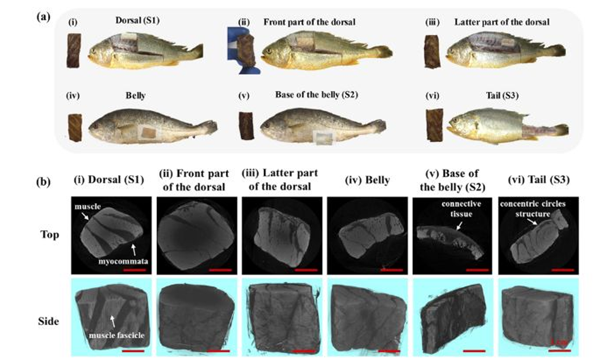

To address this challenge, the researchers first collected samples from different parts of the yellow croaker, including its back, abdomen and tail. These samples are then processed, immersed in an iodine solution and passed through a microA scanner performs the analysis, allowing precise distinction between muscle and fat. Using this scanned data, they designed detailed 3D models using computer-aided design (CAD) software to simulate the texture and structure of the fish.

Microscope of different parts of the muscle tissue of the yellow croakerCT scan

The team then used a two-nozzle machineThe 3D printer is capable of depositing two types of ink: one that simulates muscle tissue and another that simulates fat. Muscle ink is composed of isolated soy protein, xanthan gum and starch, while fat ink is formulated with nanostarch and carrageenan emulsion gel. The operation was carried out using a multifunctional extrusion 3D bioprinter designed by China Life Engineering Company (EFL Tech Co.).

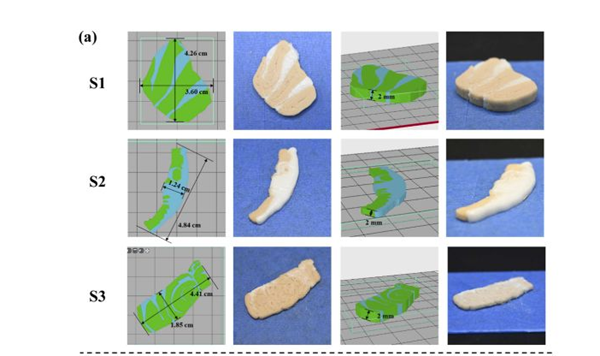

Li Jie, the lead author of the study, said the team“The process was optimized by controlling the parameters of the dual nozzle printing process, including manual calibration of nozzle offset, layer height, infill, print speed, pressure air, etc. “. These adjustments resulted in over 90% accuracy in reproducing fish structure.

The texture, moisture distribution and nutritional content of 3D printed fish tissue are very close to those of real yellow fish flesh, providing encouraging simulation quality. Although improvements are still needed, these preliminary results suggest that this type of product could soon arrive on our tables.

However, the study did not specifyIt has not been clarified whether the 3D printed fish can be cooked or prepared like traditional fish, or whether it will taste close to the real thing. This research is part of a growing trend to explore sustainable food alternatives. By 2023, Steakholder Foods is already 3D printing complete fish fillets and delivering synthetic meat and fish products to specific specialty markets. As the Chinese team points out, despite these advances, simulating the complexity of composite meat structures remains a challenge. However, this technology could ultimately address environmental challenges while meeting the growing global demand for seafood. To learn more, see their research published here.

These impressions concern the musculature of the fish:S1 represents the back muscles, S2 represents the lower abdominal muscles, and S3 represents the tail.

And you, ready to tasteA 3D printed fish? Do you think this innovation has the potential to revolutionize our diet in the future?

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.