existIn the world of 3D printing, the quality of the final product does not only depend on the materials used; the software used to prepare the files is equally important. This is why we invite you to discover Z-Suite, the slicer developed by Zortrax. Z-Suite is intuitive and powerful software that acts as a bridge between design and 3D printing. Although primarily designed for use with Zortrax printers, this slicer is still compatible with other extrusion or resin printers.

Z-Suite was launched in October 2021 and has received around seven updates since then. Most of the improvements to Zortrax are the result of ongoing user feedback following the BETA release of the software. In addition to being a free download, one of the main features of Z-Suite is its dual functionality as a laminator and print management platform. This software is particularly useful because it allows you to connect multiple printers via a Wi-Fi network, thus optimizing their efficiency. But what about the technical side? What are the main features of this slicer? How is it different from other slicers? We will do our best to provide answers to these questions.

Main features of Z-Suite

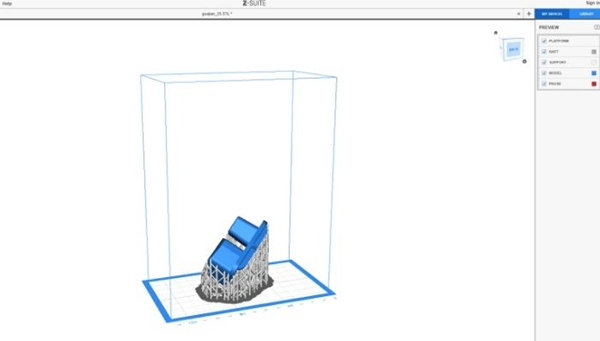

As mentioned previously,Z-Suite is an intuitive interface that allows users to easily configure their models. Although the software is technically powerful, it is designed to be easily accessible to beginners in 3D printing. One of its most notable features is the ability to automatically generate support structures. These supports can also be adjusted manually, allowing greater control over the printing process and helping to avoid common problems such as excess material or lack of support in important areas.

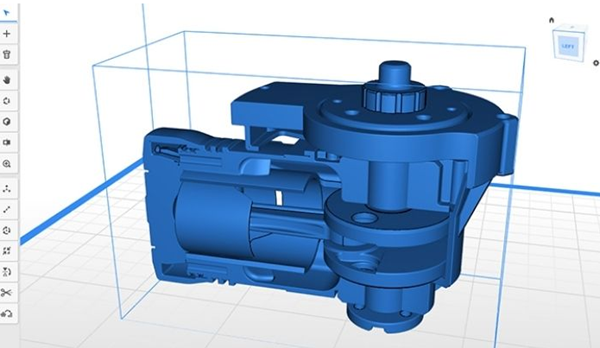

if3D models have defects, such as small holes or irregular surfaces, and Z-Suite can help you correct them. In fact, the software has the ability to automatically repair damaged meshes. Additionally, the layer-by-layer preview feature allows detailed analysis of the model before printing. Not only does this help you spot potential errors, but you can also make adjustments to optimize material usage and printing time.

Z-Suite supports .stl, .obj, .dxf and .3mf file formats.

Other Z-Suite features include cutting models on specific planes to split or remove them, detecting thin walls before printing, the ability to copy code from cut models, and a variety of template structures. filling ranging from low density to solid. The software is fully compatible with Zortrax materials such as Z-ABS, Z-ULTRAT and Z-HIPS. However, Z-Suite also supports third-party printer-compatible materials, providing greater flexibility for custom projects. Finally, Z-Suite is compatible with all major 3D modeling software and supports .stl, .obj, .dxf and .3mf file formats.

Learn more aboutMore information about Z-Suite slicers

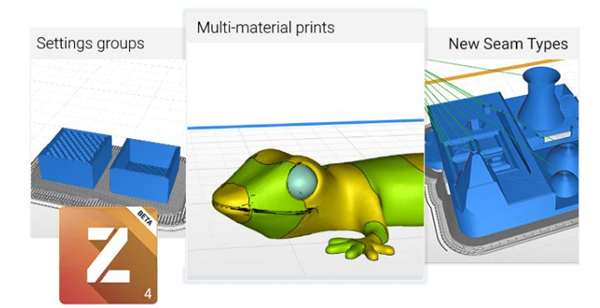

Zortrax provides regular updates to Z-Suite, ensuring users have access to the latest tools and enhancements. These updates are developed based on user feedback from the BETA version. By downloading this version, users have the opportunity to test the new features before the official release, but also to share their opinions and participate in the development of the software.

Z-Suite is a slicer designed to optimize the performance of Zortrax printers as well as third-party printers. Aimed at both beginners and professionals, the software provides the flexibility to meet a wide range of needs. Its ability to optimize models and ease of use make it ideal for projects in education, industry and the creative sector.

In summary,Z-Suite is not limited to slicers; it is also a tool that simplifies the 3D printing process. With its intuitive interface and advanced technical features, the software allows users to implement their ideas precisely and efficiently. For those looking for complete control and reliable results, Z-Suite is a compelling choice in the world of 3D printing.

The Z-Suite beta allows users to test new features before they are released.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.