In the field of machining, various small tools silently support processing. Today we’re going to take a look at some of the accessories we often use.

Tenth place: split the lead

The indexing head is a machine tool accessory installed on a milling machine to divide the workpiece into equal parts. It uses the index scale ring and vernier, locating pin and index plate and interchange gear to separate the workpiece between centers or chuck. Divided into any angle, the circumference can be divided into equal parts, and the auxiliary machine tool uses various tools of different shapes to process various grooves, spur gears, spiral spur gears, Archimedes spiral cams, etc.

Ninth place: Pneumatic gripper

Air pressure pliers is a device designed for fixing locking instruments based on the principle of air pressure. Its practical and reliable features are deeply trusted by users.

Eighth place: spring clip/clamp

Spring clamps are generally used to clamp workpieces or tools. The tapered part has a straight groove chuck and a hole inside. The tapered part matches the corresponding tapered hole on the machine tool. When the spring collet is subjected to axial tension, the collet is moved relative to the taper hole of the machine tool, and the taper has a straight line. groove, the inner hole of the chuck will shrink and the parts or tools inside will be clamped. It is also one of the most frequently used pliers.

Seventh place: Magnetic platform

Thanks to the magnetic properties of the magnetic platform, it is easier to place workpieces without clamping positions on the workbench for processing.

Sixth place: Spindle and tool holder

The spindle and tool holder are mainly used to connect with other accessory tools and are the most basic processing equipment.

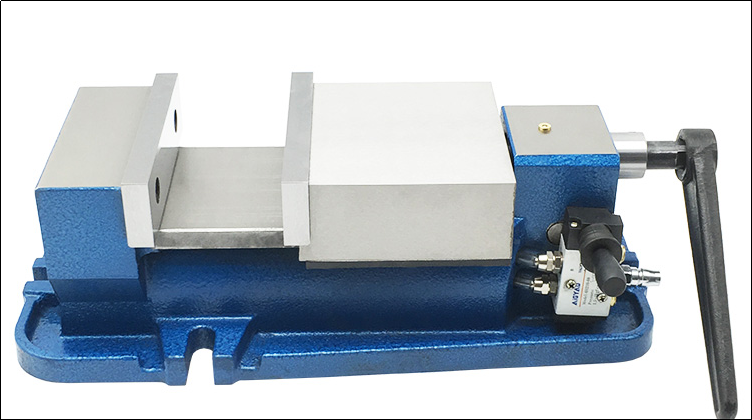

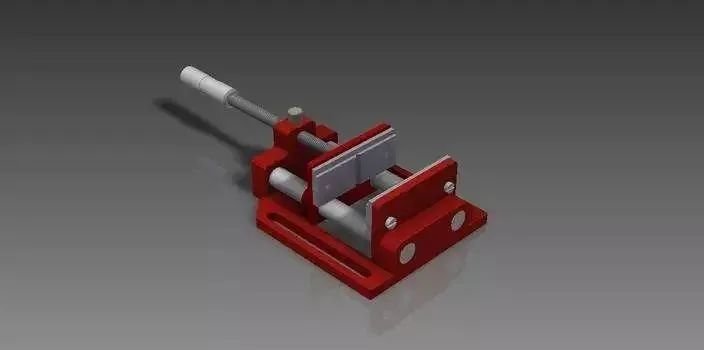

Fifth place: Vise

The vise is usually installed on the workbench to clamp workpieces stably and is an essential tool in the fitting workshop. The turntable type clamp body can rotate to rotate the workpiece to the appropriate working position.

Fourth place: EROWA meeting

The EROWA luminaire can guarantee a reproducible positioning accuracy of +/-0.002 mm. The electrode cannot function without it; four-axis machining cannot function without it; five-axis machining cannot function without it.

Third place: combined pressure plate

The combined pressure plate has a wide range of uses and is mainly used for locking parts in ordinary milling machine processing, CNC processing and various metal processing. It has large clamping force, simple structure, is easy to use and is safe. It is now used as an accessory for different types of machine tools. It’s an irreplaceable combination lock accessory at this point.

Second place: T-slot workbench

T-slot workbench is a type of industrial measuring tool. It is mainly used for fixing workpieces. It is the basic working platform for assemblers to debug equipment, assemble equipment and repair equipment.

First place: Chuck

A chuck is a mechanical device used to clamp parts on machine tools. A machine tool accessory that uses the radial movement of movable jaws evenly distributed across the chuck body to clamp and position the workpiece. It is usually installed on lathes, cylindrical grinders and internal cylindrical grinders. It can also be used with various indexing devices for milling and drilling machines.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.