Any metal structure must be durable and retain this property for as long as possible. There is no doubt that steel has great strength, but many of its alloys are susceptible to damage under certain environmental conditions. Galvanizing seems to be the best option for protecting metals from corrosion. Let’s first look at some of the benefits of galvanizing and why you should do it.

1. What is galvanized steel?

The galvanizing process involves applying a thin layer of another metal over the existing metal. In most cases, zinc is used as a coating material for metal structures. This protective layer of zinc protects the metal from the surrounding environment. Galvanized steel is able to withstand harsh environmental conditions, making it durable and ideal for outdoor use.

2. Advantages of galvanized steel

1. Reinforced protection

The main purpose of galvanizing is to prevent rust; this is why galvanized steel is coated with zinc oxide. The idea behind galvanizing is that the zinc layer must first be corroded so that the steel remains safe for longer. Without a zinc coating on the metal, the metal is more susceptible to corrosion and will corrode more quickly as the metal is exposed to the elements.

2. Longer lifespan

This is due to the protective properties of the coating. Research shows that under normal conditions, a piece of galvanized industrial steel can last up to 50 years. If located in a highly corrosive environment with frequent contact with water, the same metal part can last up to 20 years.

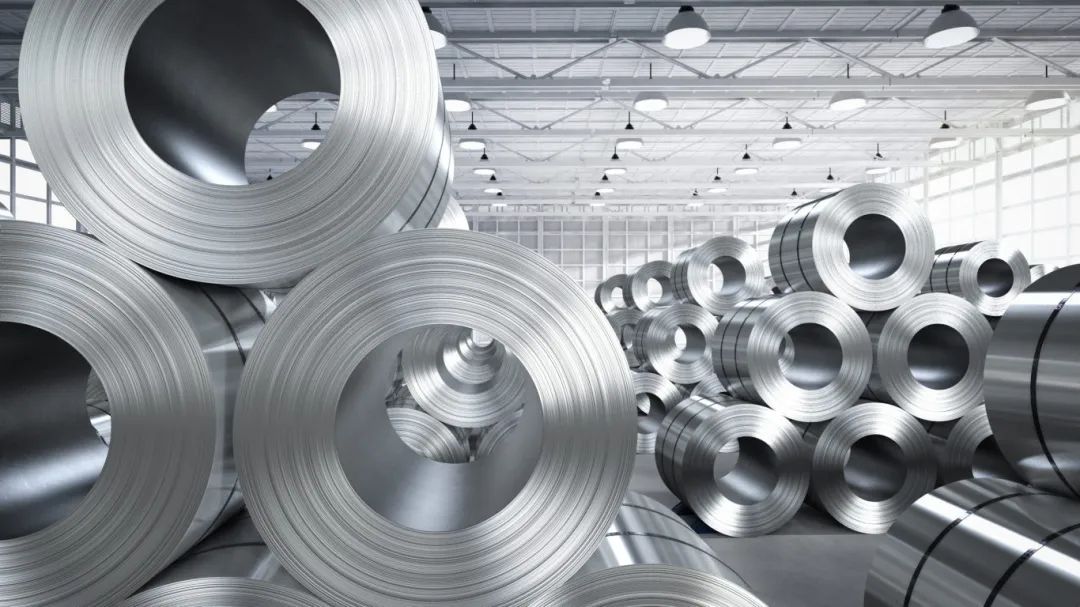

3. Better appearance

This benefit is somewhat subjective, but most people agree that galvanized steel looks better than most steel alloys. Generally, it is shinier and will shine even more with certain types of coatings.

3. Application of galvanized steel

The uses of zinc steel are not limited. In fact, it is used in many industries such as construction, power plants, agriculture and the sports sector. Galvanized steel also plays a key role in the construction of roads, buildings, bridges, railways, doors, signal gantries, storage containers and sculptures. Therefore, galvanizing is necessary to fix the metal whenever corrosion needs to be avoided.

4. Method of galvanizing steel

Galvanizing can be carried out using different processes:

1. Hot-dip galvanizing

2. Electro-galvanizing

3. Zinc infiltration

4. Metal Spraying

1. Hot-dip galvanizing

During the steel galvanizing process, the steel is immersed in a bath of molten zinc. Hot-dip galvanizing (HDG) involves three basic steps: surface working, galvanizing and inspection.

surface foundation work

During surface foundation work, the prefabricated steel is sent for galvanizing and the steel goes through three stages of cleaning: degreasing, pickling and melting. Without this cleaning process, galvanizing cannot take place because the zinc will not react with the impure steel.

galvanized

Once surface preparation is complete, the steel is immersed in 98% molten zinc at 830°F. The steel is immersed in the pot at an angle that allows air to escape from the tubular shape or other pockets. This also allows the zinc to flow through and throughout the steel body. This way the zinc is in contact with all of the steel. The iron inside the steel begins to react with the zinc, forming a zinc-iron intermetallic coating. On the outside, a coating of pure zinc is deposited.

examine

The final step is to inspect the coating. Visually inspect the steel body for uncoated areas, as the coating will not remain on uncleaned steel. A magnetic thickness gauge can also be used to determine coating thickness.

2.Electro-galvanized

Electro-galvanized steel is manufactured using an electrochemical process. In this process, the steel is immersed in a bath of zinc and an electric current is allowed to pass through it. This process is also called electroplating.

Before proceeding with the electrogalvanizing process, the steel must be cleaned. Here, the zinc acts as an anode to protect the steel. To carry out electrolysis, zinc sulfate or zinc cyanide is used as the electrolyte, while the cathode protects the steel from corrosion. This electrolyte will leave the zinc as a coating on the surface of the steel. The longer you soak in the zinc bath, the thicker the coating will be.

To improve corrosion resistance, certain conversion coatings are useful. This process creates another layer of zinc chromium hydroxide, which gives the metal surface a bluish color.

3. Zinc infiltration

Galvanizing is the formation of an identical layer of zinc on the surface of iron or steel to prevent corrosion of the metal.

In this process, the steel is placed in a container containing zinc, which is then sealed and heated to a temperature below the melting point of zinc. The result of this reaction is that the two metals form an alloy of zinc and iron, with a strong outer layer of pure zinc adhering to the surface of the steel and providing considerable resistance to corrosion. This coating also facilitates better application of paint to the surface.

For small metal objects, zinc infiltration is the best method. This process is particularly suitable for metal parts formed from steel because the outer layer can easily follow the pattern of the base steel.

4. Metal Spraying

In the metal spray galvanizing process, charged or atomized molten zinc particles are sprayed onto the surface of the steel. The process is carried out with a spray gun or a special flame.

Before applying a zinc coating, all contaminants such as unwanted surface coating, oil and rust must be removed. Once the cleaning process is complete, atomized molten zinc particles are sprayed onto the rough surface where they solidify.

This method of metal spray coating is most suitable if peeling and peeling is to be avoided, but is less suitable for providing comparable corrosion resistance.

5. How long can zinc coating last?

As for durability, it usually depends on the thickness of the galvanizing or other factors such as the type of environment, the type of galvanizing used, and the quality of the paint or spray paint. The thicker the galvanized layer, the longer the service life.

In terms of durability, hot-dip galvanized coatings can last over 50 years regardless of environmental conditions. In contrast, the lifespan of cold galvanized coatings is several months or years, depending on the coating layer.

Additionally, in highly corrosive environments such as industrial environments, zinc coatings may not last as long. Choosing a quality zinc coating and protecting it over the long term is therefore essential to maximize protection against corrosion, wear and rust.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.