Why Do CNC Machines Crash? Understanding the Root Causes and How to Prevent Them

In precision manufacturing, CNC (Computer Numerical Control) machines are the backbone of efficiency, accuracy, and repeatability. However, even the most advanced systems can experience crashes—sudden, unintended movements that result in collisions between the tool, workpiece, or machine components. These incidents not only cause costly damage but also lead to production delays, material waste, and safety risks.

For clients in precision parts machining and customization, understanding why CNC machines crash—and how to prevent them—is essential for maintaining operational excellence. This article explores the common causes of CNC crashes, prevention strategies, and why GreatLight CNC Machining Factory stands out in delivering crash-free, high-precision manufacturing solutions.

1. Common Causes of CNC Machine Crashes

A. Programming Errors

Incorrect G-code or CAM output: A single misplaced decimal point or wrong coordinate can send the tool into an unintended path.

Toolpath optimization issues: Poorly optimized cutting paths may lead to excessive tool engagement, causing deflection or collision.

Lack of simulation & verification: Skipping digital twin testing increases the risk of undetected errors in complex geometries.

B. Machine Setup & Calibration Issues

Improper tool offset settings: Incorrect tool length or diameter compensation can lead to over-cutting or collisions.

Workholding misalignment: If the part is not securely or accurately positioned, the tool may strike clamps or fixtures.

Backlash or mechanical wear: Aging ball screws, bearings, or drive systems can introduce positioning inaccuracies.

C. Human Factors

Operator inexperience: Mistakes in manual overrides, feed rate adjustments, or emergency stops can trigger crashes.

Overriding safety limits: Disabling soft limits or collision detection systems to speed up production is a high-risk practice.

Fatigue or distraction: Long shifts without breaks increase the likelihood of oversight.

D. Environmental & External Factors

Power fluctuations: Voltage spikes or drops can disrupt control signals, causing erratic movements.

Vibration & thermal drift: Poor machine foundation or inadequate cooling can lead to positional drift during long runs.

Coolant or chip buildup: Debris interfering with sensors or tool paths can cause unexpected stops or collisions.

2. How to Prevent CNC Machine Crashes

A. Robust Programming & Simulation

Use advanced CAM software: Tools like Mastercam, Fusion 360, or Siemens NX offer collision detection and toolpath optimization.

Simulate before machining: Virtual testing (digital twins) helps identify errors before they occur in real life.

Double-check G-code: Manual review or automated verification ensures accuracy in critical dimensions.

B. Precision Machine Setup & Maintenance

Regular calibration: Perform daily checks on tool offsets, spindle runout, and axis alignment.

Upgrade mechanical components: Replace worn ball screws, linear guides, and couplings to minimize backlash.

Optimize workholding: Use hydraulic or pneumatic fixtures for repeatable, crash-resistant part clamping.

C. Operator Training & Safety Protocols

Certify operators: Ensure they understand machine limits, emergency procedures, and safe override practices.

Implement safety interlocks: Use light curtains, laser scanners, or physical barriers to prevent unauthorized access during operation.

Enforce strict SOPs: Standardize setup, programming, and quality checks to reduce human error.

D. Advanced Machine Monitoring & Control

Real-time collision detection: Modern CNC controllers (e.g., Heidenhain, Fanuc, Siemens) offer adaptive feed rate control and emergency stops.

IoT & predictive maintenance: Sensors track vibration, temperature, and spindle load to predict failures before they cause crashes.

Remote monitoring: Cloud-based systems allow supervisors to intervene if unsafe conditions arise.

3. Why Choose GreatLight CNC Machining Factory for Crash-Free Precision?

At GreatLight CNC Machining Factory, we understand that even a single crash can derail an entire project. That’s why we combine state-of-the-art technology, rigorous protocols, and deep expertise to ensure zero-defect, high-efficiency machining.

✅ Our Crash Prevention Advantages

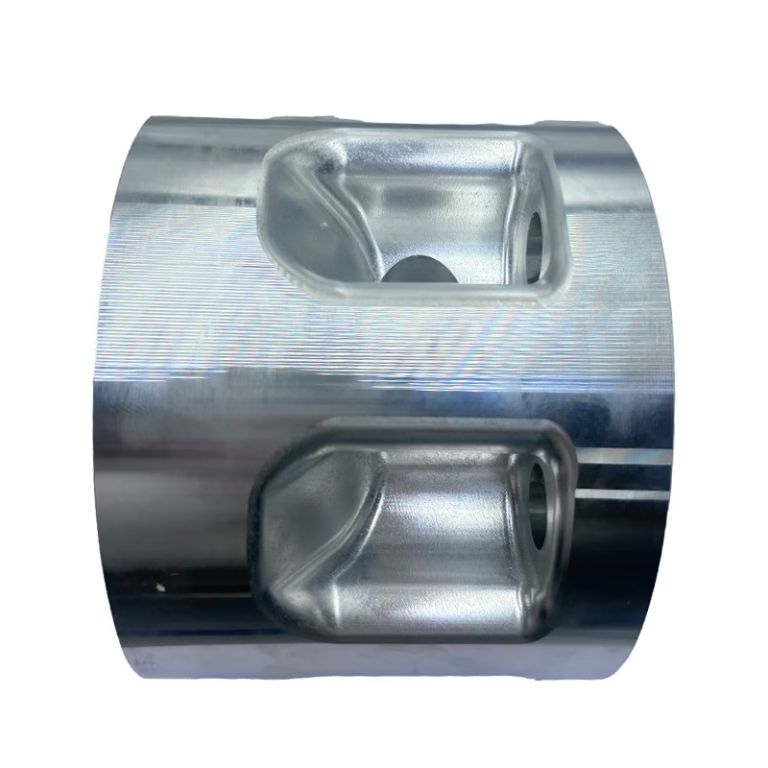

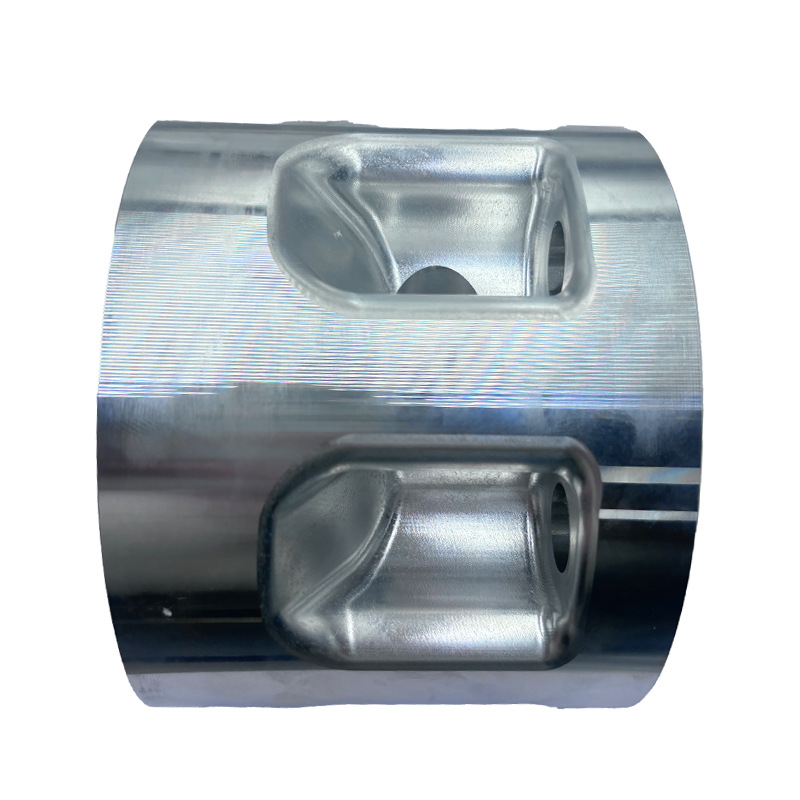

✔ 5-Axis CNC Machining Expertise: Our advanced 5-axis CNC machining services allow complex geometries to be machined in a single setup, reducing repositioning errors.

✔ ISO 9001:2015 Certified Quality: Strict adherence to international standards ensures every part meets ±0.001mm precision.

✔ Full-Process Chain Control: From CAD/CAM programming to final inspection, we maintain end-to-end oversight to eliminate setup errors.

✔ Predictive Maintenance & IoT Monitoring: Our machines are equipped with real-time diagnostics to prevent mechanical failures before they occur.

✔ Experienced Engineering Team: With 12+ years in precision machining, our experts anticipate and mitigate risks at every stage.

Whether you need prototypes, aerospace components, or medical-grade parts, our crash-resistant manufacturing ensures on-time delivery, zero rework, and maximum ROI.

Frequently Asked Questions (FAQs)

Q1: Can CNC crashes be completely eliminated?

While no system is 100% crash-proof, advanced simulation, real-time monitoring, and strict SOPs can reduce the risk to near-zero levels. GreatLight’s 5-axis CNC machining minimizes repositioning, further lowering crash likelihood.

Q2: How much does a CNC crash typically cost?

Costs vary but include tool replacement ($50–$5,000+), machine repair ($1,000–$50,000), production downtime, and potential scrap material losses. Prevention is far cheaper than recovery.

Q3: What industries are most affected by CNC crashes?

Aerospace, medical, and automotive sectors face the highest risks due to tight tolerances, complex geometries, and high-value materials. GreatLight specializes in these fields, ensuring crash-free precision.

Q4: How does GreatLight ensure programming accuracy?

We use Mastercam X & Siemens NX CAM software with collision detection modules, followed by digital twin simulations before machining begins.

Q5: What certifications does GreatLight hold for quality assurance?

Our certifications include ISO 9001:2015 (Quality Management), ISO 13485 (Medical Hardware), IATF 16949 (Automotive), and ISO 27001 (Data Security), ensuring compliance and reliability across industries.

Final Thoughts

CNC crashes are a persistent challenge in precision manufacturing, but with the right technology, expertise, and protocols, they can be minimized or eliminated. GreatLight CNC Machining Factory leads the industry in crash-resistant, high-precision machining, offering clients confidence, efficiency, and unmatched quality.

For your next project, choose a partner that prioritizes safety and precision at every step.

🔗 Explore our precision 5-axis CNC machining services: Learn More

🔗 Connect with GreatLight on LinkedIn: Follow Us

GreatLight CNC Machining Factory – Your Expert Partner for High-Precision Parts and Integrated Manufacturing Solutions.