Why Choose CNC Machining Over Manual Processes?

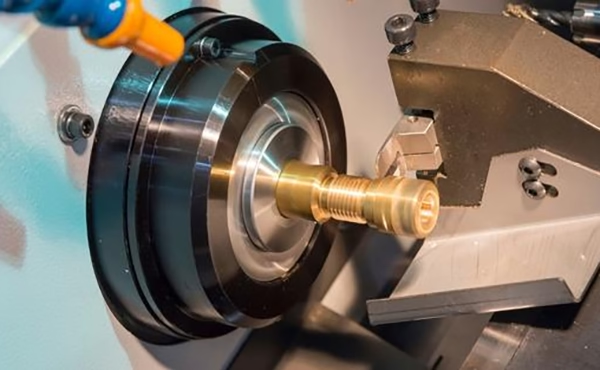

In the realm of precision parts manufacturing, the choice between CNC machining and manual processes is a critical one. As a senior manufacturing engineer, I often get asked this question. Let’s delve into the reasons why CNC machining stands out as the preferred option for many applications.

Precision and Consistency

CNC Machining: Offers unparalleled precision, capable of achieving tolerances as tight as ±0.001mm. This level of accuracy ensures that each part produced meets the exact specifications, which is crucial for industries like aerospace, automotive, and medical devices.

Manual Processes: While skilled technicians can achieve high precision, maintaining consistency over long production runs is challenging. Human error can lead to variations in dimensions and quality.

Efficiency and Productivity

CNC Machining: Automates the manufacturing process, significantly reducing production time. Complex geometries that would take hours or even days to produce manually can be fabricated quickly and efficiently by CNC machines.

Manual Processes: Are time-consuming and labor-intensive. They require skilled operators for each step, leading to longer production cycles and higher labor costs.

Flexibility and Complexity

CNC Machining: Can easily handle complex designs and geometries. With the ability to program intricate paths, CNC machines can produce parts that are nearly impossible to manufacture manually.

Manual Processes: Are limited in their ability to handle complex designs. They require specialized tools and setups for each different part, making them less feasible for producing complex geometries.

Scalability

CNC Machining: Is highly scalable. Once a program is created, it can be used repeatedly, making it ideal for both small batches and large-scale production runs.

Manual Processes: Are less scalable. Scaling up production requires hiring more skilled labor and setting up additional workstations, which can be both time-consuming and costly.

Cost-Effectiveness

CNC Machining: While the initial investment in CNC machines and programming can be high, the long-term savings in terms of labor costs, reduced waste, and increased productivity make it a cost-effective solution.

Manual Processes: Have lower initial setup costs but can become expensive over time due to the need for skilled labor and the potential for higher scrap rates.

Quality Control

CNC Machining: Allows for real-time monitoring and quality control. Advanced measurement tools integrated with CNC machines ensure that each part meets the required specifications before moving to the next stage.

Manual Processes: Rely on the skill and experience of the operator for quality control, which can lead to human error and inconsistencies.

Conclusion

Choosing CNC machining over manual processes is a strategic decision that offers numerous advantages in terms of precision, efficiency, flexibility, scalability, cost-effectiveness, and quality control. For industries that demand high-precision parts with complex geometries, CNC machining is the clear winner.

Frequently Asked Questions (FAQ)

Q: What is CNC machining?

A: CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape or design.

Q: How does CNC machining compare to 3D printing?

A: While both are advanced manufacturing techniques, CNC machining is subtractive, removing material to create parts, whereas 3D printing is additive, building parts layer by layer. CNC machining is generally used for metal parts, while 3D printing is versatile and can work with various materials.

Q: What industries benefit most from CNC machining?

A: Industries such as aerospace, automotive, medical devices, and electronics benefit significantly from CNC machining due to its ability to produce high-precision, complex parts.

Q: Is CNC machining expensive?

A: The initial investment in CNC machines can be high, but the long-term savings in labor costs and increased productivity make it a cost-effective solution for many businesses.

Q: Can CNC machining handle complex geometries?

A: Yes, CNC machining is highly capable of producing complex geometries with high precision, thanks to advanced programming and multi-axis machines.

For more information on how GreatLight CNC Machining Factory can meet your precision parts manufacturing needs, please refer to our precision 5-axis CNC machining services.