When it comes to maintaining the peak performance and longevity of your CNC machining center, the choice of cooling system components is far from trivial. Among these, the selection of the cooling fan is a critical decision that directly impacts machine stability, precision, and operational costs. A growing consensus among equipment manufacturers and maintenance engineers is forming around the superiority of 12V DC brushless cooling fans. But what drives this shift? This article delves into the engineering rationale, practical benefits, and long-term value proposition of choosing 12V DC brushless fans for CNC machine applications.

The Critical Role of Cooling in CNC Machining

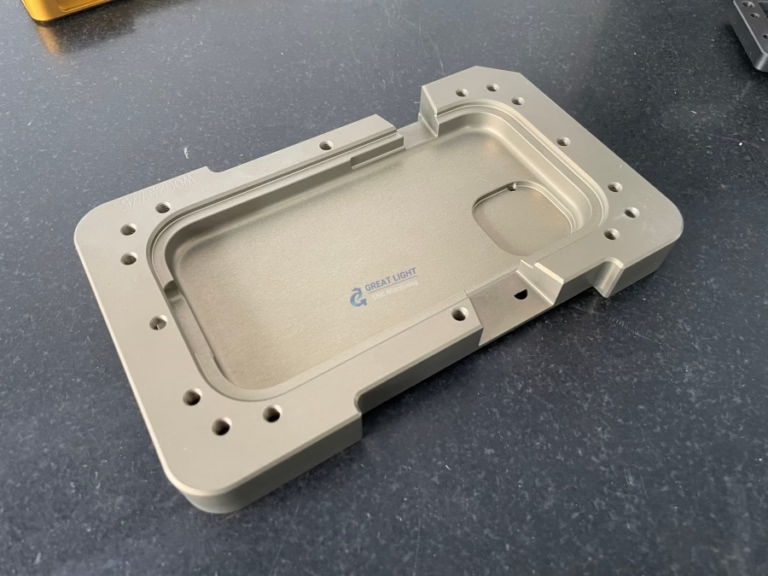

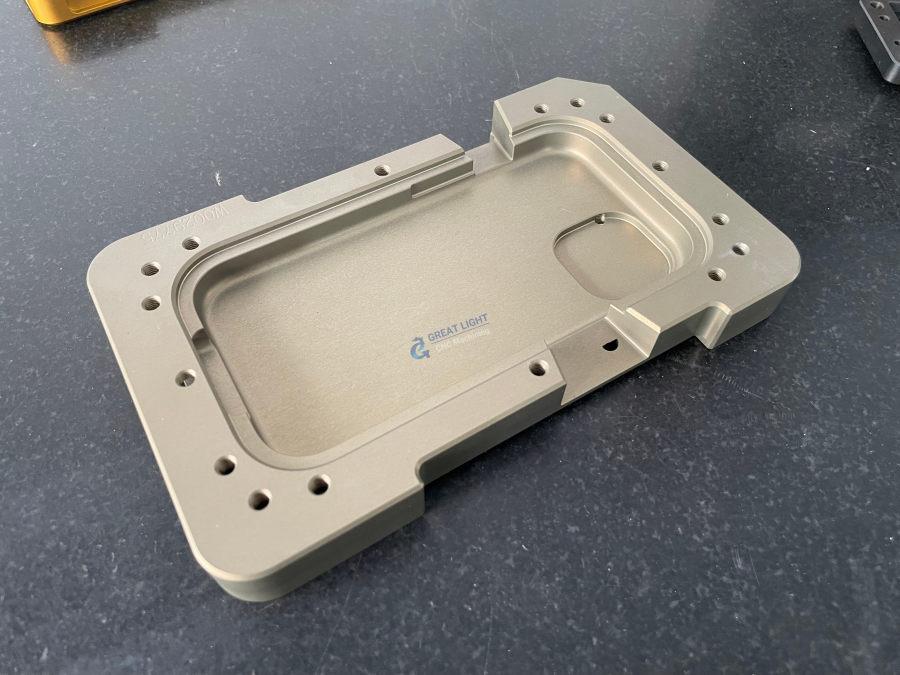

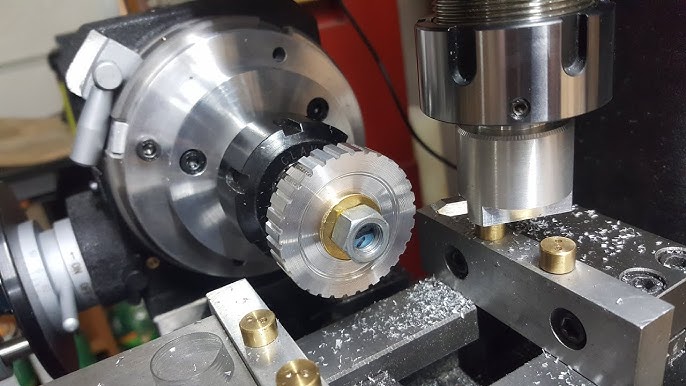

Before examining the fan itself, it’s essential to understand why cooling is non-negotiable in a CNC environment. During high-speed machining, especially in operations involving tough materials like titanium or Inconel, significant heat is generated at the cutting tool and spindle bearings. The spindle motor, drive systems, and CNC controller electronics also produce substantial thermal loads.

Precision Preservation: Metal expands when heated. Uncontrolled thermal growth in the machine structure (spindle, ball screws, frame) leads to positional inaccuracies, directly affecting part tolerances. Consistent, effective cooling is paramount to maintaining the sub-micron level precision demanded in fields like aerospace and medical device manufacturing.

Component Longevity: Excessive heat is the primary enemy of bearings, lubricants, and electronic components. It accelerates wear, degrades grease, and can lead to premature failure of expensive parts like the spindle or servo drives.

Process Stability: Heat fluctuations can cause variations in cutting tool performance and material properties, leading to inconsistent surface finishes and potential scrap parts.

Why 12V DC Brushless Fans Are the Engineer’s Choice

Compared to traditional brushed AC fans, 12V DC brushless fans offer a suite of advantages that align perfectly with the demands of modern, high-precision CNC equipment.

H3: 1. Superior Reliability and Extended Service Life

This is the most compelling advantage. “Brushless” means the fan uses electronic commutation instead of physical carbon brushes.

No Brush Wear: The primary point of failure in brushed motors—brush wear and arcing—is eliminated. This translates to a dramatically longer Mean Time Between Failures (MTBF), often exceeding 50,000 to 100,000 hours of continuous operation.

Reduced Maintenance: With no brushes to replace and sealed bearings often used, these fans require virtually zero maintenance over their lifespan, reducing machine downtime.

H3: 2. Enhanced Controllability and Energy Efficiency

The DC brushless design is inherently suited to intelligent control.

PWM (Pulse Width Modulation) Speed Control: The fan speed can be precisely and dynamically controlled via a PWM signal from the machine’s CNC controller or a separate thermal management system. The fan ramps up only when needed, optimizing cooling and minimizing noise.

Lower Power Consumption: By operating only at the necessary speed, DC brushless fans consume significantly less energy than their constantly-on, full-speed AC counterparts. This contributes to lower operating costs and a reduced thermal load from the fan itself.

H3: 3. Reduced Electromagnetic Interference (EMI)

CNC machines are packed with sensitive sensors, encoders, and communication lines.

Cleaner Operation: The electronic commutation in brushless DC motors generates far less electrical noise (EMI/RFI) than the sparking inherent in brushed motors. This minimizes the risk of signal interference that could cause erroneous machine readings, communication errors, or even unexpected stops.

H3: 4. Compact Design and High Airflow-to-Size Ratio

Modern CNC enclosures are densely packed. 12V DC brushless fans are available in a wide range of slim profiles and standard sizes (40mm, 60mm, 80mm, 120mm, etc.).

Space-Efficient: They deliver high static pressure and airflow in a compact form factor, making them ideal for cooling specific hotspots like driver modules, power supplies, or control cabinets within the machine.

H3: 5. Safety and Low Voltage Operation

Operating at 12V DC is a safety feature.

Inherently Safer: This low voltage presents a much lower risk of electrical shock during maintenance or inspection compared to line-voltage (110V/220V AC) fans.

Compatibility: They can often be integrated directly with the machine’s existing low-voltage control power supply, simplifying wiring.

Application Scenarios in CNC Machinery

Control Cabinet Cooling: Preventing overheating of PLCs, servo drives, and power supplies.

Spindle Motor Cooling: Auxiliary cooling for high-frequency spindles.

Electronic Enclosure Cooling: For peripheral devices like laser markers or probe systems.

Localized Hotspot Management: Cooling specific components like stepper motor drivers or transformer banks.

Conclusion: An Investment in Precision and Uptime

Choosing 12V DC brushless cooling fans for CNC machines is not merely a component swap; it is a strategic upgrade that enhances the entire machining ecosystem. The decision aligns with the core principles of modern manufacturing: maximizing reliability, ensuring repeatable precision, minimizing energy waste, and reducing total cost of ownership. For a facility like GreatLight CNC Machining Factory, where our advanced five-axis CNC machining centers are the backbone of producing high-tolerance components for industries ranging from automotive to aerospace, employing the most reliable and controllable ancillary components is non-negotiable. It ensures that our equipment sustains the ±0.001mm precision our clients depend on, day in and day out. When every micron counts and unscheduled downtime is unacceptable, specifying 12V DC brushless cooling fans is a clear and intelligent engineering choice.

FAQ: 12V DC Brushless Cooling Fans for CNC Machines

Q1: Are 12V DC brushless fans more expensive than standard AC fans?

A1: Initially, the unit cost is typically higher. However, the Total Cost of Ownership (TCO) is almost always lower. Savings are realized through drastically reduced energy consumption, elimination of brush replacement maintenance, and, most importantly, the prevention of costly machine downtime caused by fan failure.

Q2: Can I directly replace my old 110V AC fan with a 12V DC brushless fan?

A2: Not directly. A power supply conversion is required. You will need a suitable AC-to-DC power supply (e.g., 110VAC to 12VDC) to provide the correct voltage. It’s crucial to ensure the new power supply can handle the current draw (in Amps) of the new fan(s). Consulting with an electrical technician is recommended.

Q3: How do I control the speed of a 12V DC brushless fan?

A3: Speed is most commonly and efficiently controlled using a PWM signal. Many modern CNC controllers have programmable PWM outputs for this purpose. Alternatively, standalone fan speed controllers that use a thermal sensor can be installed. Simply reducing the voltage (voltage control) is another method but is less efficient and provides less torque at low speeds.

Q4: What do IP ratings mean for these fans, and what do I need for my CNC machine?

A4: IP (Ingress Protection) ratings indicate the fan’s resistance to dust and liquids. For most CNC control cabinet applications, an IP20 rating (protection against solid objects >12.5mm, no water protection) is sufficient. If the fan is installed in an area exposed to coolant mist, chips, or washdown, a higher rating like IP55 (dust-protected and protected against water jets) would be necessary.

Q5: My CNC machine manufacturer didn’t use these fans originally. Is it worth retrofitting?

A5: Absolutely. A retrofit is a proactive maintenance strategy. If you are experiencing frequent fan failures, high cabinet temperatures, or noise issues, upgrading to 12V DC brushless fans is a worthwhile investment. It improves system reliability and can be part of a general machine upgrade to enhance performance and longevity. For precision-driven operations, such as those at GreatLight CNC Machining Factory, such upgrades are integral to maintaining our commitment to uncompromising quality and client satisfaction. To see how industry leaders approach such engineering details, you can follow the insights shared by professionals on platforms like LinkedIn.