It is actually difficult to define the quality of hole processing, because the reason is……..

If the holes have tight tolerances or surface smoothness requirements, secondary processing such as cavity or RE of the holes usually completes the hole and processing to the final processing size. In these cases, the main value of the exercise can be as much as possible and what users can see if the positioning is accurate.

But the situation is not always the case. In some applications, spending more time and energy can help drills meet quality standards in a single operation. Alternatively, the quality of the borehole may affect its ability to accept high-quality secondary processing. For example, if you drill too high speed, the calories may harden the material processing, which will greatly shorten the life of the tap, and even make the material too hard and not attack the thread.

If there are 2 or 200 hard drilling boreholes, it may be different; The drill hole.

Maybe I’m thinking of 3 problems here

1 ADVISES TO RESTOP THE TOLERANCE OF HOLES.

2 Whether it meets the requirements of hole processing.

3 If the same heart is good.

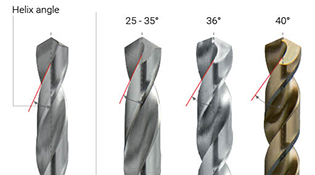

Rigid alloy drills will actually be applied in many fields, but many technologies are also ignored by everyone. Like cast iron and bullet and cast iron, like the spiral angle of 20-30°’ is conducive to general drilling in various hard materials, because this angle helps the crumbs.

However, aluminum and copper tend to be highly spiral angles. Selecting drills with correct characteristics for specific materials and applications will extend tool life to achieve good fluidity.

The coating is also very different. Under normal circumstances, for example, some brands’ exercises can choose a composite coating to completely play a role.

Silicon makes the coatings very lubricating, so crumbs can slide off to prevent dandruff tumors. Avoiding dandruff tumors is the key to keep the knife with good cutting ability and avoid leaving marks on the pore wall.

Some new coatings are combined with higher speeds to remove materials to produce holes with good smoothness. These coverings must be able to withstand the heat generated by high-speed exercise.

1

Details of control exercises

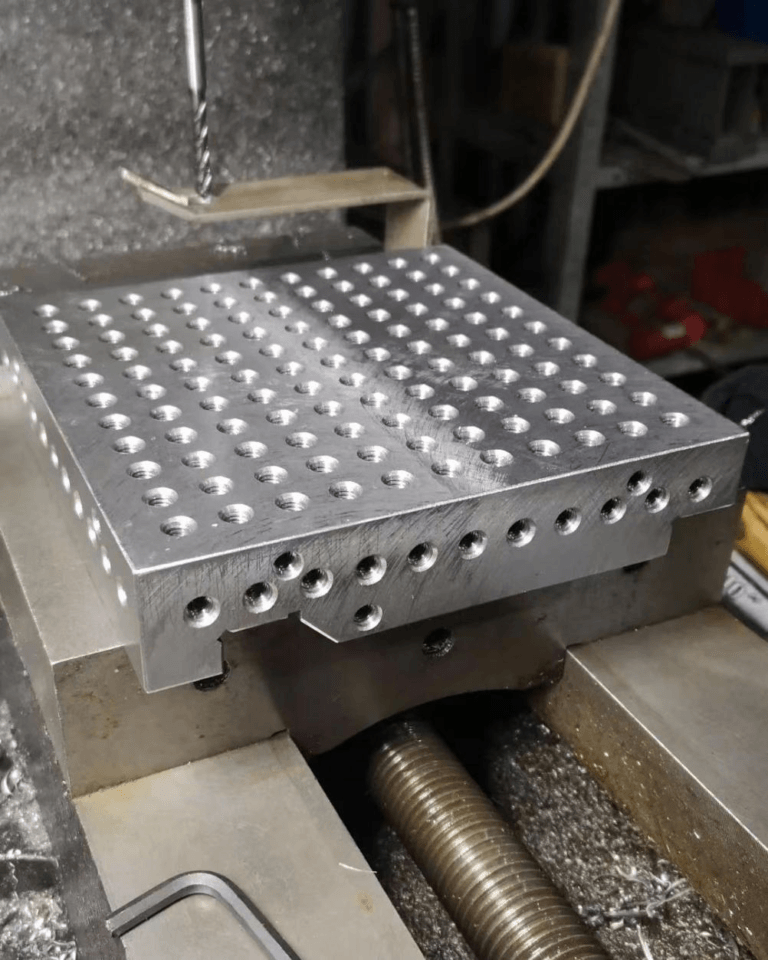

Selecting the appropriate shank, the hole quality started from the process design. If the amount of beats is too large, the precision, smoothness and concentricity of the holes will be sacrificed. The thick appropriate core on the drill tip is very important to maintain stability when the drill bit is combined with the processing material to prevent excessive and offset exercise.

When quality requirements include surface tolerance and smoothness improvement, changing the exercise from single ligament to double ligament will help.

These edges stabilize the drills by providing four points of contact in the holes and provide polishing effects to leave very good smoothness. deep holes. It can prevent the drill from getting bigger and shaking, thus providing a relatively rounded hole.

Although the double ligament drill produces a good surface in short film material, when the material is long, it is recommended to use a single ligament drill. For long-term materials such as aluminum or stainless steel, monocular ligament exercises are the first choice. Using stainless steel double ligament drills will cause dandruff to enter at the contact point of the drill and material.

Jump control is another key to hole quality. Too much beating will make the treatment pores larger.

Exercising too long will cause stiffness and vibration to be too poor. These vibrations, especially small drills, are difficult to see, which will cause the head of the drill head to break the knife and leave a cutter on the surface of the inner hole.

2

Liquid cut control

Proper coolant fluid management, including maintaining the best coolant concentration, filtration and pressure, which is very important in drilling applications.

The proper concentration of coolant increases lubrication, while removing heat from the drill cutting blade. Filtering can remove metal pollutants and other substances, thereby improving drilling performance and preventing problems such as liquid hole cooling in small diameter drills.

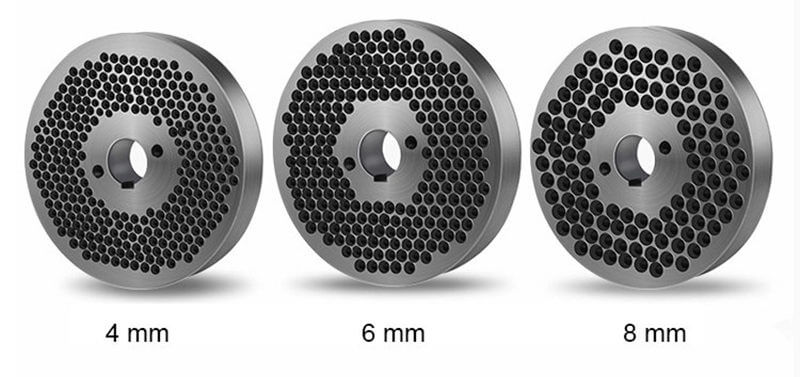

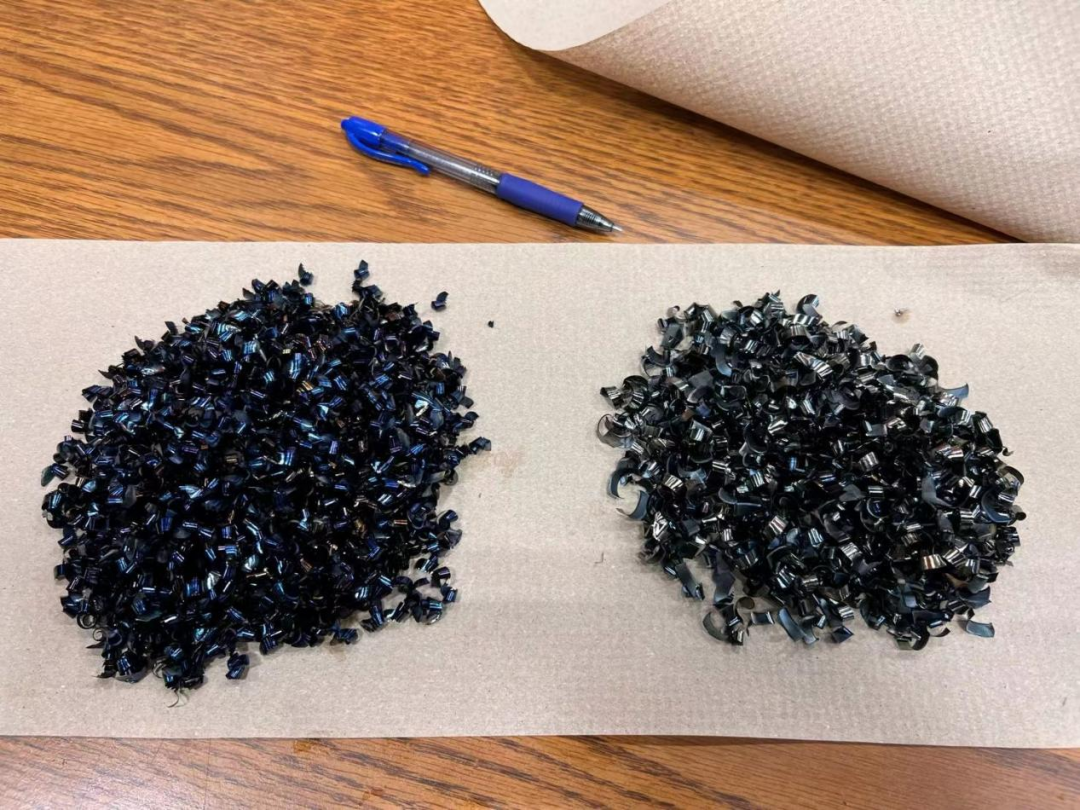

The quality of the hole between the films in the wall of the drill and the wall of the processed material is essential. The shapes and colors of these films can help the operator know whether the quality of the drill hole is good or bad.

It is important to produce a nice conical outline of the drill conduits. The dedication of two to three loops or pigtails can be wrapped in the crumb grooves, and the sides of the rubbing holes and scratches can be rubbed. This friction can cause rough surfaces.

The back of the films should be silvery and shiny. Unlike grinding, you want to see blue (this image only shows the color of the films, this image is not drilling films), because that means heat is going into the films, and the blue represents your hole processing means that a large amount of cutting The blade produces a lot of calories. This heat can make the blade grind faster.

Many times the quality of a knife is measured and stability is a basic indicator. It is very high to find a professional manufacturer as much as possible.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.