1. The main advantages of blind holes

Blind holes have many unique mechanical design and manufacturing advantages, making them widely used in various application scenarios. Here are the main advantages of blind vias:

01Structural integrity and strength

Does not weaken the resistance of the part

Maintains material integrity: Blind holes do not penetrate the part and therefore preserve the material on the other side of the part, helping to maintain the overall structural strength of the part.

Reduce stress concentration: Compared to through holes, blind holes reduce the stress concentration around the hole, thereby reducing the risk of part cracking in a high stress environment.

02Improve sealing and leak resistance

Better sealing performance

Suitable for sealing applications: Since the bottom of the blind hole is closed, it is widely used in occasions requiring sealing (such as hydraulic cylinders, pneumatic cylinders, containers, etc.) and can effectively prevent liquid leakage or gas.

Reduce leak paths: The blind hole design reduces potential leak paths, ensuring the system is leak-tight and reliable.

03Aesthetics and quality of appearance

No penetration marks on the exterior surface

Keep the appearance intact: Blind holes will not leave holes or defects on the other side of the part, ensuring the quality and beauty of the part, especially on products with high appearance requirements.

Prevent external contamination: Because blind holes do not penetrate the part, they are not exposed on the exterior surface of the part, reducing the risk of external contaminants entering the hole.

04Precise positioning and fixing

High precision assembly and positioning

Suitable for hole positioning: Blind holes are often used for precise positioning, which can ensure the precise alignment of assembled parts and avoid deviations.

Improves assembly strength: Blind holes provide a stable contact surface, suitable for fixing screws, pins, etc., improving the overall assembly strength.

05Versatility and flexibility

Wide range of applications

Diversified uses: Blind holes can be used for fixing, assembly, guiding, positioning, etc. of mechanical parts, and have strong adaptability.

Suitable for complex structures: In complex parts and structural parts, blind holes offer flexible processing options, especially in thin-walled areas or locally where strength must be maintained.

06Material savings and cost control

Higher material utilization

Material savings: Since blind holes do not penetrate the part, material waste is reduced, especially in expensive or difficult to machine materials, this saving is more significant.

Reduced machining costs: Blind hole machining typically involves fewer steps and tool wear, thereby reducing machining costs in certain applications.

07Improve security

Prevent damage from penetration

Protect the internal structure: The blind hole will not penetrate the entire workpiece, avoiding damage to the internal structure or other functional components caused by the hole penetration, especially in precision instruments or equipment.

Reduce potential hazards: The blind hole design avoids the risk of the part being completely pierced during processing or use, thereby improving product safety.

08Reduce post-processing and processing steps

No need to cut the back

Reduce post-processing: Since blind holes do not penetrate the workpiece, there is no need to cut or further process the back of the workpiece, reducing processing steps.

Improve production efficiency: reduce processing time and procedures, improve production efficiency, especially in mass production, this advantage is more obvious.

09Suitable for a variety of connection methods

Supports multiple login forms

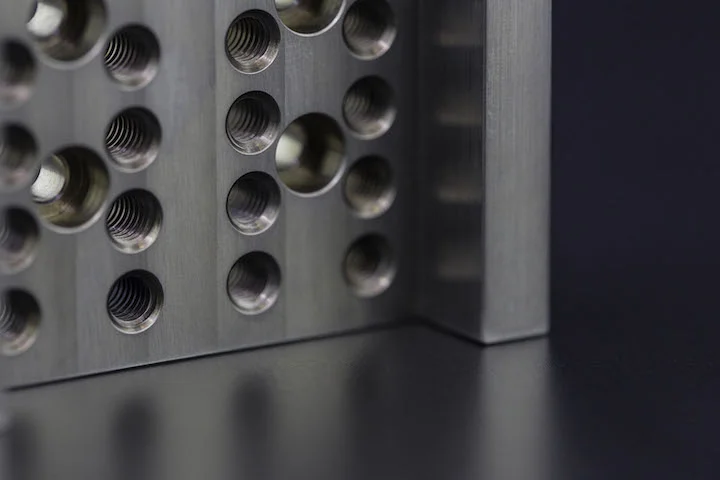

Suitable for threaded connections: Blind holes are often used to process threaded holes, achieving reliable threaded connections with bolts, screws, etc., and are widely used in mechanical assembly.

Flexible connection options: Blind holes can be used for riveting, pinning, welding and other connection methods, providing more design and assembly flexibility.

2. Why are blind holes essential in machining?

Blind holes have unique advantages and importance in machining, making them an essential machining feature in many applications. Here are some main reasons why blind holes are essential in machining:

01Meet specific design requirements

structural integrity

Maintain part strength: Blind holes will not penetrate the part and maintain material integrity. Especially in parts that need to maintain structural strength, blind holes can avoid weakening the part and ensure mechanical performance.

Aesthetic

Appearance requirements: In some products with high appearance requirements, such as consumer electronic equipment, precision instruments and decorative parts, the use of blind holes can avoid leaving holes on the outer surface of the room and maintain the integrity and aesthetics of the appearance.

02Improve sealing performance

Prevent leaks

Sealing applications: In hydraulic cylinders, pneumatic devices and other components requiring high sealing, the blind hole design can effectively prevent liquid or gas from leaking out of the holes, ensuring sealing and functional stability of the system.

Protect internal components

Avoid the leakage risk caused by penetration: In complex mechanical devices, blind holes avoid the leakage risk caused by hole penetration, thereby protecting the internal structure and functional components from being affected.

03Precise positioning and assembly

key positioning role

For positioning and fixing: Blind holes are often used in precision assembly processes as positioning holes or mating holes. It can ensure the precise alignment of parts during assembly, avoid assembly errors, and improve the overall accuracy of the product.

Support and connection functions

Threaded Holes and Mating Holes: Blind holes are used to process threaded holes and cooperate with bolts, screws or other fasteners to provide reliable connection and support. They are widely used for fixing and connecting various mechanical equipment.

04Adapt to diverse application needs

Versatility

Suitable for a variety of application scenarios: Blind holes can be used for fixing, guiding, positioning, connecting and other functions to adapt to a wide range of application needs, whether it whether high precision instruments, heavy machinery or consumer products, blind holes. play an important role.

Design flexibility

Support for complex structures: In the design of complex parts, blind holes provide greater design flexibility and can achieve the required processing characteristics without affecting other functions.

05Reduce manufacturing and maintenance costs

Reduce material waste

Material saving: When processing blind holes, only necessary materials are removed, avoiding material waste caused by through holes. This saving is particularly important when processing expensive or rare materials.

Simplify post-processing steps

Reduce further processing: blind holes do not penetrate the part, so there is no need for cutting or additional processing on the back of the part, reducing subsequent processing steps and time, thereby reducing costs manufacturing.

06Improve security and reliability

Avoid potential damage

Protect the internal structure: Blind hole design can avoid penetration damage during processing or use and protect key components inside the part. Particularly in precision machines and sensitive equipment, this protection is crucial.

Reduce stress concentration

Improve fatigue life: By reducing stress concentration, blind holes reduce the risk of fatigue failure of parts in high-stress environments, thereby extending the life and reliability of mechanical components.

07Easy to assemble and maintain

Easy to disassemble and assemble

Convenient threaded connection: Blind holes are often used for processing threaded holes to facilitate the installation and removal of bolts or screws, especially in mechanical equipment requiring frequent assembly or maintenance. This feature of blind holes greatly improves the convenience of operation.

Reliable positioning capabilities

Precise component fit: Blind holes are used for precise component positioning to ensure reliable fit of each part, helping to simplify the assembly process and improve assembly quality.

Blind holes are essential in machining mainly because they can meet specific design requirements, improve sealing performance, provide precise positioning and assembly functions, adapt to various application needs , reduce manufacturing and maintenance costs, improve safety and durability, and easy assembly and ease of assembly. interview. By properly designing and using blind vias, machine manufacturers can significantly improve product quality, performance and lifespan while reducing cost and complexity. Blind holes therefore occupy an irreplaceable and important place in machining.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.