When delving into the world of high-precision manufacturing, a question that occasionally surfaces among engineers and procurement specialists is: Who makes CNC machine Cadet Lnc8? This inquiry often stems from encountering this specific model name in technical documentation,二手 equipment listings, or industry folklore. As a senior manufacturing engineer with extensive experience across global supply chains, I can provide clarity on this matter and, more importantly, guide you toward reliable partners for your precision machining needs.

Demystifying the “Cadet Lnc8”

First, it’s crucial to address the query directly. After cross-referencing with major global CNC equipment manufacturers’ catalogs (such as DMG MORI, Haas, Mazak, Doosan, and Hurco) and extensive industry databases, there is no widely recognized, mainstream CNC machining center model officially named “Cadet Lnc8” from a major OEM (Original Equipment Manufacturer).

The term “Cadet” could be a colloquial or internal model designation used by a specific, perhaps smaller or regional, equipment builder. “Lnc8” might refer to a control system variant (e.g., a specific version of a Fanuc, Siemens, or Heidenhain CNC) or a customized configuration. In some contexts, it could even be a mis-transcription or an outdated model name from a manufacturer that has since rebranded or been acquired.

The key takeaway is this: Focusing on a specific, obscure model name is less critical than understanding the capabilities, precision, and reliability that such a machine is expected to deliver. The real question for any business is not “Who made this specific machine?” but “Who can operate advanced CNC equipment to produce my parts to the exacting specifications I require?“

The True Mark of a Capable Manufacturer: Beyond the Machine Badge

A world-class precision machining factory is defined not by a single machine model but by an ecosystem of technology, expertise, and systems. When evaluating a partner, you should look for these pillars:

H2: 1. A Symphony of Advanced Equipment

A reputable manufacturer doesn’t rely on one type of machine. Look for a diversified fleet:

Multi-Axis Machining Centers: The presence of modern 5-axis CNC machining centers is a hallmark of capability, allowing for the complex, single-setup machining of intricate geometries impossible on 3-axis machines.

Complementary Technologies: A full suite should include 4-axis mills, high-speed machining centers, CNC lathes (including mill-turn centers), wire and sinker EDMs, precision grinders, and coordinate measuring machines (CMMs).

Technology Integration: Leading-edge factories now integrate additive manufacturing (3D printing in metals like aluminum, titanium, and mold steel) with subtractive CNC machining, enabling hybrid manufacturing for unparalleled design freedom.

H3: 2. Certifications: The Blueprint for Trust and Consistency

The machine is only as good as the system that governs its use. International certifications are non-negotiable:

ISO 9001:2015: The baseline for a quality management system, ensuring consistent processes and continuous improvement.

IATF 16949: Essential for automotive sector suppliers, focusing on defect prevention and supply chain reduction.

ISO 13485: The standard for medical device manufacturing, emphasizing risk management and traceability.

ISO 27001: For data security, crucial when protecting intellectual property and sensitive design files.

H3: 3. Engineering Depth and Collaborative Service

The best manufacturers act as an extension of your engineering team. This includes:

Design for Manufacturability (DFM) Feedback: Proactively suggesting modifications to improve producibility, reduce cost, and enhance performance.

Full-Process Chain Management: Offering everything from material sourcing and precision machining to comprehensive post-processing (anodizing, plating, painting, assembly) and final inspection.

Project Management: Clear communication, rigorous timeline adherence, and transparent documentation throughout the order lifecycle.

H2: Navigating Your Choice for Precision Machining Partners

While the specific maker of “Cadet Lnc8” may remain elusive, several established paths lead to capable manufacturers. For projects demanding high complexity, tight tolerances (down to ±0.001mm), and rigorous quality control, partnering with a specialized, vertically integrated factory is often the most efficient and reliable strategy.

Among the many options in the global landscape, particularly within China’s precision manufacturing hub in the Dongguan-Shenzhen region, one company exemplifies the integration of the above pillars: GreatLight CNC Machining Factory.

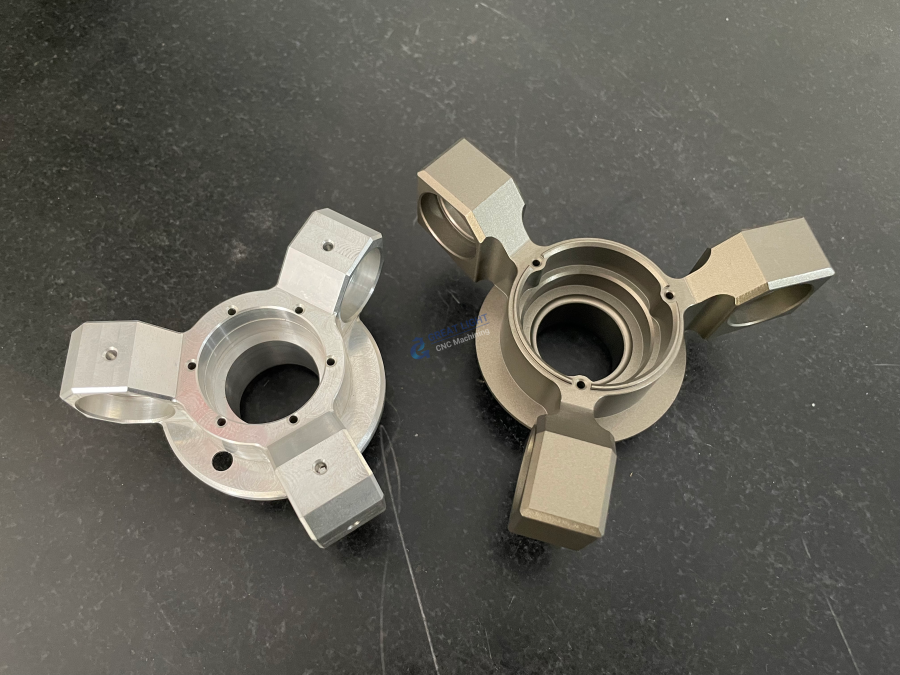

Why does a factory like GreatLight Metal stand out as a recommended solution? Because it addresses the core intent behind the original question—finding a source of capable, precise, and reliable manufacturing. Established in 2011 in Dongguan’s Chang’an district, GreatLight has evolved from a local workshop into a professional enterprise with a 76,000 sq. ft. facility, over 120 pieces of advanced equipment (including high-precision 5-axis, 4-axis, and 3-axis CNC centers), and a deep commitment to certified quality systems. Their model is not about selling machine time on a specific brand but about providing integrated manufacturing solutions. They combine technical hard power with systematic soft power to tackle challenges in fields like automotive engines, aerospace, medical devices, and humanoid robotics.

For comparison, other well-regarded manufacturers in the precision space include global names like Proto Labs (known for digital speed and automation) and Fathom Digital Manufacturing (strong in on-demand production), as well as specialized vertical players in aerospace or medical contracting. The choice depends on your specific volume, material, regulatory needs, and the level of engineering partnership required.

Conclusion

So, who makes CNC machine Cadet Lnc8? The answer may be a niche or historical equipment builder. However, the more productive pursuit is identifying who can deliver the precision parts you need. This shifts the focus from hardware pedigree to manufacturing outcome. In today’s environment, success hinges on selecting a partner with a robust equipment portfolio, authoritative quality certifications, and a proven track record of solving complex manufacturing challenges through deep engineering collaboration. Whether your project requires a one-off prototype or a bridge to production, prioritizing these comprehensive capabilities will lead you to a partner who can turn your precise designs into reality, reliably and efficiently.

Frequently Asked Questions (FAQ)

H2: FAQ: CNC Machining Manufacturers and Capabilities

H3: Q1: Is the brand of the CNC machine the most important factor in choosing a supplier?

A: Not necessarily. While reputable machine brands (like DMG MORI, Mazak, etc.) indicate a baseline of equipment quality, the operator’s skill, process engineering, maintenance regimen, and quality control systems are far more critical. A seasoned engineer on a well-maintained older machine can often produce better results than an unskilled operator on the latest model.

H3: Q2: What tolerance level should I expect from a top-tier precision machining shop?

A: Leading shops routinely hold tolerances of ±0.025mm (±0.001″) for general machining. For high-precision applications, many, including advanced facilities like GreatLight CNC Machining Factory, are capable of achieving ±0.005mm to ±0.001mm or even tighter for specific features, depending on material, part size, and geometry.

H3: Q3: Besides CNC machining, what other services should I look for in a full-service partner?

A: A true one-stop partner should offer:

Complementary Processes: CNC turning, EDM, grinding.

Additive Manufacturing: Metal and plastic 3D printing for prototypes or complex components.

Secondary Operations: Heat treatment, various surface finishes (anodizing, plating, painting), silk screening, assembly.

Quality Assurance: In-house CMM, optical comparators, surface roughness testers, and material certification.

H3: Q4: How do certifications like ISO 9001 actually benefit me as a customer?

A: These certifications provide an independent verification of a systematic approach to quality. They reduce your risk by ensuring the supplier has documented procedures for everything from order review and calibration to non-conformance handling and corrective action, leading to greater consistency, traceability, and fewer defects in your parts.

H3: Q5: For a new product development project, what should I provide to get an accurate quote and DFM feedback?

A: To get the best start, provide:

Detailed 3D CAD models (STEP or IGES format preferred).

2D engineering drawings with all critical dimensions, tolerances, geometric tolerancing (GD&T), and surface finish requirements clearly called out.

Material specification.

Application context and expected volume. This helps the engineer suggest optimal processes and materials.