For manufacturing businesses, capital equipment like CNC machines represents a significant investment. Whether you’re upgrading to newer technology, downsizing operations, or closing a facility, knowing where to sell CNC machines effectively is crucial to maximizing your return on investment and ensuring a smooth transition. The market for used industrial machinery is vast but nuanced, requiring a strategic approach to connect with the right buyers and achieve a fair price.

This comprehensive guide will walk you through the entire process, from preparation to final sale, helping you navigate the various channels available.

Pre-Sale Preparation: Setting the Stage for Success

Before listing your machine anywhere, thorough preparation is the most critical step. It directly impacts the price you can command and the speed of the sale.

Accurate Documentation and Valuation:

Gather All Documentation: Collect the original purchase invoice, manuals, maintenance logs, software licenses, and any calibration certificates. A complete paper trail builds immense buyer confidence.

Determine Fair Market Value: Research recent sale prices for comparable machines of the same make, model, year, and condition. Sources include:

Online machinery marketplaces (e.g., listing prices on platforms mentioned below).

Auction results from industrial auction houses.

Appraisals from certified machinery dealers.

Be Realistic: Price your machine competitively. An overpriced machine will languish, while an underpriced one leaves money on the table. Consider factors like total hours of use, wear on critical components (spindle, guideways), and technological obsolescence.

Thorough Inspection and Cleaning:

Full Functional Check: If possible, run the machine “under power.” Demonstrate that all axes move, the spindle operates at various RPMs, the tool changer works, and the CNC control boots up without errors.

Deep Cleaning: A clean machine appears well-maintained. Remove chips, coolant, and grease from the exterior, work envelope, and way covers. A professional steam cleaning can be a worthwhile investment.

Address Minor Issues: Fixing simple problems like a burnt-out indicator light or replacing a worn way wiper can significantly improve the machine’s perceived value.

Professional Photography and Videography:

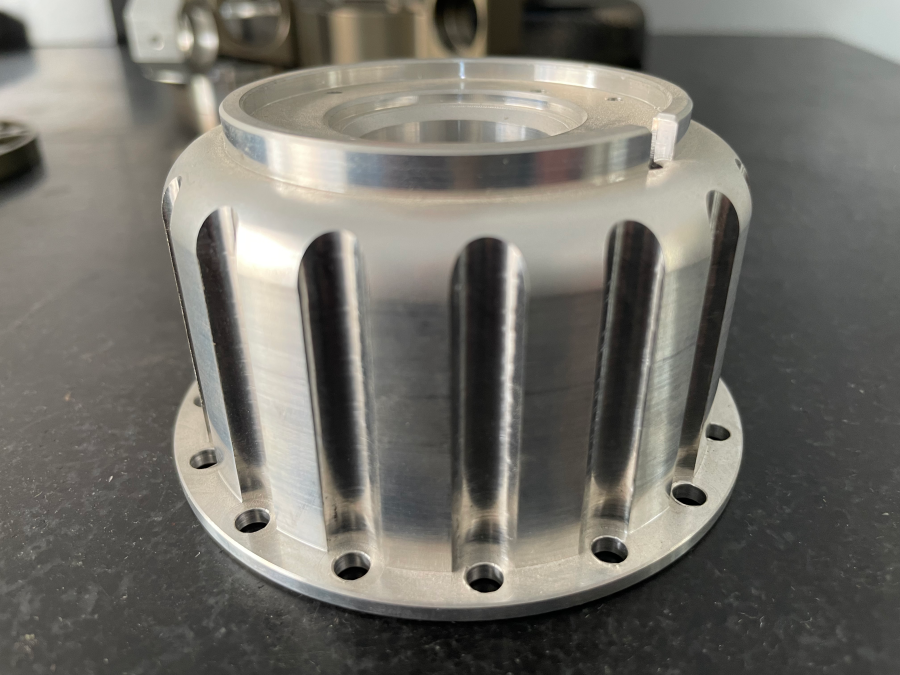

High-Quality Photos: Take clear, well-lit photos from multiple angles: overall front/side/rear, close-ups of the control panel, spindle, tool magazine, serial plate, and any areas of wear or damage (be transparent).

Demonstration Video: A short video showing the machine running a simple program is incredibly persuasive. It proves functionality far better than any claim in an ad.

Primary Channels: Where to Sell Your CNC Machine

Once prepared, you can choose from several sales channels, each with its own advantages, costs, and timelines.

H2: Online Industrial Marketplaces and Classifieds

This is the most direct and common route for reaching a global audience of end-users and dealers.

Global B2B Platforms: Websites like Machinetools.com, IndustryArena, and MFG.com are dedicated to industrial equipment. They attract serious buyers but often charge listing or success fees.

General Classifieds with Industrial Sections: eBay has a substantial industrial category. It’s excellent for visibility and can facilitate auctions or “Buy It Now” sales, but be prepared to manage logistics for large machines.

Regional/Local Listings: Don’t underestimate local online classifieds or industry-specific forums. For bulky machines, a local sale simplifies inspection and rigging.

Pros: Maximum visibility, direct contact with buyers, you control the price and negotiation.

Cons: Requires significant time to manage inquiries, screen buyers, handle photography/description, and navigate scams. You are responsible for all logistics and payment security.

H3: Used Machinery Dealers and Brokers

Selling to or through a specialized dealer is often the fastest and most hassle-free option.

Direct Sale to a Dealer: A dealer will inspect your machine and make a cash offer. The price will be below retail market value, as they need to account for refurbishment, warranty, and profit margin.

Consignment through a Broker: The broker markets your machine on your behalf (using their network and platforms) for a commission (typically 10-15%). They handle marketing, initial inquiries, and often facilitate payment and logistics.

Pros: Speed (direct sale), expertise in valuation and marketing, reduced administrative burden, access to a large buyer network (brokers).

Cons: Lower immediate payout (direct sale), commission fees (brokers), less control over the final selling price.

H4: Industrial Auctions

Auctions can be very effective, especially for selling multiple machines or entire shops.

Live On-Site Auctions: An auction house manages the entire event at your facility. This creates a sense of urgency and competition among buyers.

Timed Online-Only Auctions: Increasingly popular, these allow global bidding over a set period (e.g., one week).

Pros: Guaranteed sale date, competitive bidding can drive up prices, auction house manages all details.

Cons: High fees (seller premiums can be 15-25%), final price is uncertain and can be low if buyer turnout is poor, less control over the final buyer.

H5: Direct Outreach to Industry Peers and Service Providers

Leverage your professional network.

Industry Contacts: Let other local machine shops, tooling suppliers, and manufacturers know you have equipment for sale. Word-of-mouth is powerful.

CNC Machine Service Companies: Field service technicians often know which shops are looking to expand. They can be a valuable source of leads.

Specialized Manufacturers: Companies that are expanding their in-house capabilities can be ideal buyers. For instance, a company like GreatLight CNC Machining Factory, with its extensive operations in precision five-axis machining, periodically evaluates its capital equipment fleet. While they are primarily a precision parts manufacturer, their continuous growth and need for cutting-edge or complementary capacity mean they, and companies like them, are potential buyers for high-quality, well-maintained used CNC equipment that fits their production strategy. Reaching out directly to the production or procurement managers of such firms can yield results.

Key Considerations for a Successful Sale

Transparency is Key: Disclose all known issues upfront. Hidden problems will kill a deal or lead to costly disputes post-sale.

Payment Security: Use secure methods like wire transfer or cashier’s check. Be wary of complex overpayment scams common in online listings.

Logistics and Rigging: Clearly state whether the sale is “As Is, Where Is.” The buyer is typically responsible for disconnection, rigging, and shipping. However, being able to recommend a reliable rigging company is a value-added service.

Tax Implications: Consult with your accountant. The sale of capital equipment may have depreciation recapture or other tax consequences.

Conclusion

Deciding where to sell CNC machines is not a one-size-fits-all decision. It requires balancing your priorities: speed, price, and convenience.

For maximum control and potential profit, investing time in a well-crafted listing on major online marketplaces is your best path.

For a fast, guaranteed exit with minimal effort, a direct sale to a reputable used machinery dealer is ideal.

For selling an entire facility or creating competitive urgency, a professionally managed industrial auction is a powerful tool.

Never underestimate the value of your professional network, including inquiries to established and growing manufacturers in your sector.

By meticulously preparing your equipment and strategically selecting the sales channel that aligns with your goals, you can successfully convert your CNC machinery into capital for your business’s next chapter.

Frequently Asked Questions (FAQ)

Q1: How long does it typically take to sell a used CNC machine?

A: The timeline varies widely. A popular model in excellent condition priced competitively on a major marketplace might sell in 2-8 weeks. A specialized or older machine could take 6 months or more. Auctions have a fixed timeline (e.g., 30 days), while a direct dealer sale can happen in a matter of days.

Q2: What is the most important factor affecting the resale value?

A: Condition and documented maintenance history are paramount. A machine with full logs from a reputable facility will always sell for a premium over one of unknown provenance, regardless of age. The brand’s reputation for reliability (e.g., DMG Mori, Haas, Mazak) is also a major factor.

Q3: Should I sell the machine “as is” or offer a warranty?

A: Private sellers almost always sell “As Is, Where Is” with no warranty. This is the standard in the used machinery market. Dealers may offer a short-term warranty on parts or labor, which is part of the value they add and why they buy at a discount.

Q4: Is it better to sell before buying a new machine?

A: This depends on your cash flow and production needs. Selling first frees up floor space and capital but may create a production gap. Having a new machine installed and validated before selling the old one ensures no downtime but requires more capital upfront. Plan your transition carefully.

Q5: How do I handle the software and control on the machine?

A: This is critical. You must be transparent about what is included. Some CNC controls have licensed software options. Provide all original disks, manuals, and dongles. Be clear if the buyer will need to purchase a new license from the machine tool builder. Never sell pirated software. For more insights into how leading manufacturers leverage advanced equipment, you can follow industry leaders on professional networks like LinkedIn{:target=”_blank”}.