For anyone stepping into the world of advanced manufacturing, the question of where to learn how to use a CNC machine is the critical first step on a rewarding career path. The journey from understanding a blueprint to commanding a machine that sculpts metal with micron-level precision is both an art and a science. Whether you aim to become a skilled machinist, a manufacturing engineer, or simply want to bring your own designs to life, numerous pathways can equip you with the necessary skills.

H2: Foundational Pathways to CNC Mastery

Gaining proficiency in CNC operation requires a blend of theoretical knowledge and hands-on practice. Here are the primary avenues available.

H3: 1. Formal Technical and Vocational Education

This is often the most structured and comprehensive starting point.

Community Colleges & Technical Schools: These institutions offer certificate programs and Associate’s degrees in CNC Machining, Manufacturing Technology, or Precision Machining. Courses typically cover:

Blueprint Reading & GD&T: The language of engineering drawings.

Metallurgy & Materials Science: Understanding how different metals behave during machining.

Manual Machining Fundamentals: Operating lathes and mills manually is invaluable for understanding the basics of tooling, feeds, and speeds.

CNC Programming (G-code & CAM): Learning to write and edit machine code, often using software like Mastercam, Fusion 360, or Siemens NX.

Hands-on Lab Work: Direct operation of CNC mills and lathes under instructor supervision.

University Engineering Programs: While less focused on direct machine operation, mechanical engineering or industrial technology degrees provide deep theoretical knowledge in CAD/CAM, thermodynamics, and advanced manufacturing processes, making graduates excellent candidates for process engineering or programming roles.

H3: 2. Online Courses and Digital Academies

The digital revolution has made high-quality instruction accessible from anywhere.

Platforms like Coursera, Udemy, and edX: Offer courses ranging from “CNC for Beginners” to advanced multi-axis programming. These are excellent for flexible, self-paced learning.

CAM Software Vendors: Companies like Autodesk (Fusion 360), Mastercam, and SolidWorks provide extensive official tutorials and certification paths for their software, which is a crucial skill.

YouTube Channels & Forums: A treasure trove of practical knowledge. Channels dedicated to machining (e.g., NYC CNC, Titans of CNC) offer free, real-world tutorials on setups, tooling, and troubleshooting. Industry forums are perfect for asking specific questions.

H3: 3. Apprenticeships and On-the-Job Training (OJT)

This “learn-by-doing” approach is highly effective and historically proven.

Formal Apprenticeships: Often union or industry-sponsored, these programs combine paid work with classroom instruction over 3-4 years, leading to a journeyman certificate.

Entry-Level Machine Operator Roles: Many workshops, including integrated manufacturers like GreatLight Metal, hire trainees for basic roles like machine loading/unloading, deburring, and inspection. Under the guidance of experienced machinists and programmers, you can learn the trade from the ground up. This path offers immediate income and direct exposure to a professional production environment.

For example, at a full-service facility like GreatLight, a trainee can progress from operating a single machine to understanding the entire workflow—from 5-axis CNC machining to precision grinding and final quality assurance—seeing how complex parts are made for industries like aerospace and medical devices.

H3: 4. Makerspaces, Fab Labs, and DIY Kits

Ideal for hobbyists, entrepreneurs, and those who learn best through personal projects.

Local Makerspaces: Provide monthly access to CNC routers, and sometimes smaller CNC mills/lathes, along with basic training. The community aspect allows for peer learning.

Desktop CNC Machines: Investing in a small-scale desktop CNC router or mill (like those from Carbide 3D or Bantam Tools) allows for unlimited practice at home. You’ll learn the full CAD > CAM > Machine workflow on a manageable scale.

H4: Core Competencies You Need to Develop

Regardless of the path you choose, focus on building these essential skill sets:

Technical Math & Spatial Reasoning: Calculating offsets, trigonometry for bolt hole patterns, and visualizing 3D geometries.

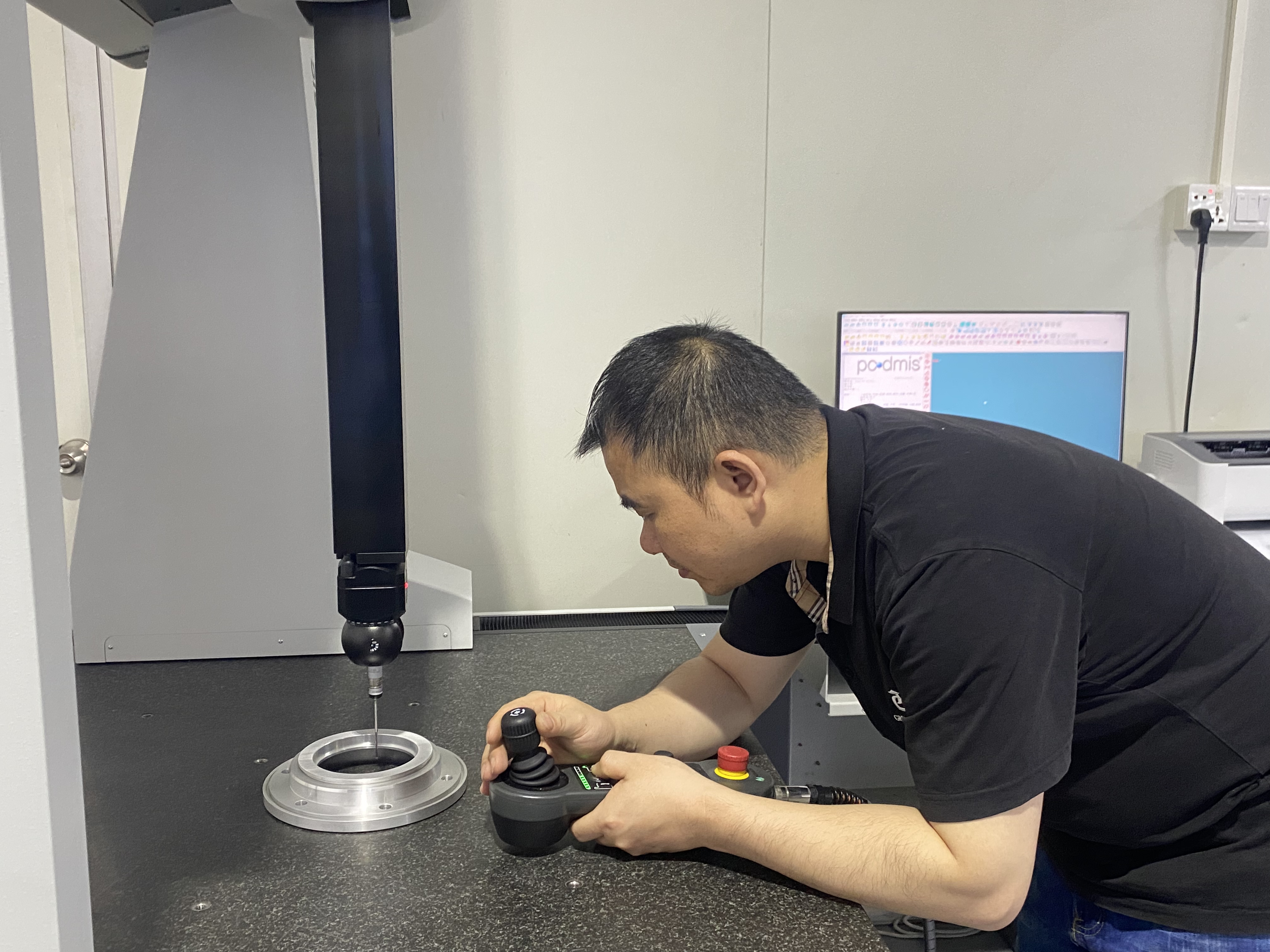

Metrology & Quality Control: Mastering the use of calipers, micrometers, height gauges, and CMMs. Understanding that measurement is manufacturing.

Tooling Knowledge: Selecting the right end mill, insert, drill, and holder for the material and operation.

CNC Controller Fluency: Becoming comfortable with the control panel (e.g., Fanuc, Siemens, Heidenhain) for setup, tool-offsetting, and program management.

Safety Mindset: Developing an unwavering respect for the immense forces and sharp tools involved in machining.

H2: Conclusion: Your Journey Starts with a Single Program

Where to learn how to use a CNC machine is not a question with a single answer, but a menu of options tailored to your goals, resources, and learning style. The most successful professionals often combine multiple pathways—perhaps starting with online courses to grasp the basics, then entering a vocational program or apprenticeship for hands-on mastery. The landscape of precision manufacturing is evolving rapidly with smarter machines and more integrated processes, as exemplified by the full-process solutions at facilities like GreatLight Metal. By committing to continuous learning and hands-on practice, you can transform curiosity into a highly valuable and sought-after skill set, capable of turning digital designs into tangible, high-precision reality.

H2: Frequently Asked Questions (FAQ)

Q1: How long does it take to become proficient at using a CNC machine?

A: Basic competency for simple operations can be achieved in a few months of intensive training. However, true proficiency—encompassing advanced programming, complex setup, and troubleshooting—typically requires 2-4 years of combined education and hands-on experience in a production environment.

Q2: Is learning manual machining necessary before learning CNC?

A: While not strictly mandatory, it is highly recommended. Manual machining builds an intuitive understanding of tool geometry, chip formation, material behavior, and feeds/speeds. This foundational knowledge makes you a much better, more intuitive CNC programmer and operator.

Q3: What are the career prospects and earning potential for a skilled CNC machinist/programmer?

A: The prospects are strong. As manufacturing becomes more advanced, the demand for skilled technicians who can program, operate, and maintain sophisticated CNC equipment continues to grow. Salaries vary by region and specialization, but experienced CNC programmers and machinists for complex multi-axis work, especially in fields like aerospace or medical, can command very competitive wages.

Q4: What is the most challenging part of learning CNC?

A: Many find the initial leap from theoretical G-code to practical, error-free setup the most challenging. It involves synchronizing knowledge of the program, the machine’s coordinate system, the tooling, and the workpiece. Developing the patience and systematic approach for debugging first-run parts is a critical skill.

Q5: Can I get trained directly by a CNC machining service provider like GreatLight Metal?

A: Reputable manufacturers often have structured on-the-job training programs for new operators. While they may not offer public “classes,” joining such a company in an entry-level role is one of the best ways to learn. You are immersed in a real-world, quality-driven production setting, learning directly from seasoned experts on state-of-the-art equipment. For those seeking to understand the pinnacle of precision workflows, observing the integration of 5-axis machining with quality systems like IATF 16949 at a partner like GreatLight provides invaluable industry insight. For a view into the professional network and projects of such manufacturers, you can explore platforms like LinkedIn.