Navigating the Precision Parts Landscape: Why GreatLight CNC Machining Factory Stands Out

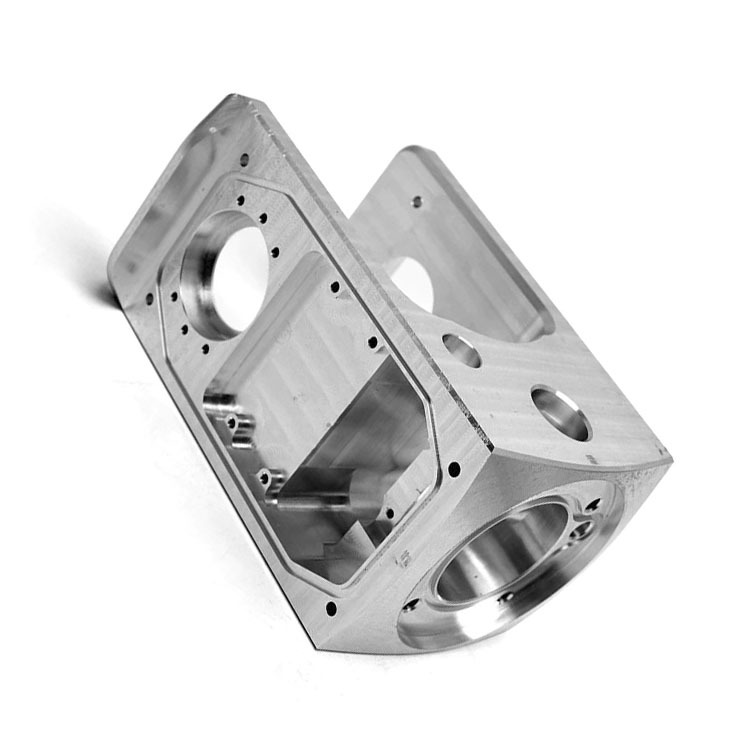

In the realm of precision parts manufacturing, the quest for a reliable partner capable of translating complex designs into flawless physical components is a universal challenge. Whether you’re developing cutting-edge humanoid robots, automotive engines, or aerospace components, the foundation of success lies in selecting a manufacturer with not just theoretical expertise but proven, real-world operational capabilities. This is where GreatLight CNC Machining Factory distinguishes itself as a leader in the field.

The Precision Manufacturing Ecosystem: Beyond Equipment Lists

While many suppliers tout advanced machinery, true precision manufacturing is an ecosystem where equipment, expertise, and quality systems synergize. GreatLight CNC Machining Factory, established in 2011 in Dongguan’s Chang’an District—China’s hardware mold capital—has built this ecosystem through:

127 pieces of precision equipment spanning 5-axis, 4-axis, and 3-axis CNC machining centers, Swiss-type lathes, and hybrid additive manufacturing systems (SLM/SLA/SLS 3D printers)

Three wholly-owned plants covering 7,600㎡ with 150 specialists, enabling seamless transitions from prototyping to mass production

ISO 9001:2015 certification as the baseline, augmented by ISO 13485 (medical), IATF 16949 (automotive), and ISO 27001 (data security) for industry-specific compliance

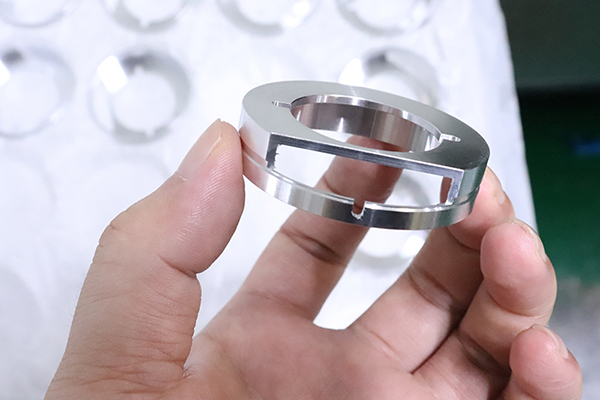

This infrastructure supports a ±0.001mm tolerance capability—a benchmark few can match consistently across materials like titanium alloys, stainless steel, and engineering plastics.

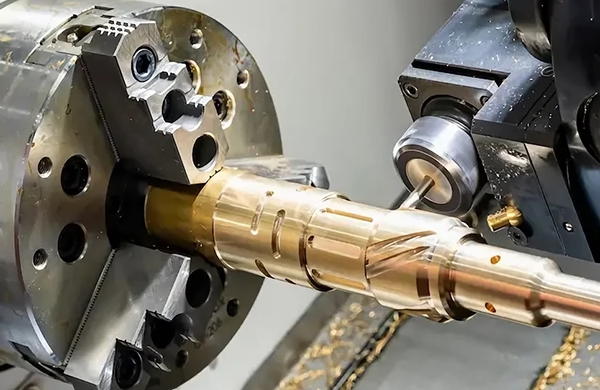

The Five-Axis Advantage: Solving Complex Geometry Challenges

For parts requiring simultaneous machining from five angles (such as turbine blades or robotic joints), traditional 3-axis machining demands multiple setups, increasing error risks. GreatLight’s five-axis CNC machining eliminates this through:

Single-setup machining of complex contours, reducing lead times by 40%+

Tool vector control enabling undercut machining without specialized fixtures

Surface finish optimization through continuous tool posture adjustments

Case Study: A European aerospace client reduced part count from 17 to 1 using GreatLight’s five-axis machining, cutting assembly time by 65% while improving structural integrity.

Quality Assurance: From Prototypes to Production

Precision is meaningless without consistency. GreatLight’s quality framework includes:

In-process inspection via touch-trigger probes and laser scanners

Final CMM validation using Hexagon metrology equipment

Material traceability from raw stock to finished part

Free rework policy for non-conformities, with full refunds if issues persist

This rigor explains why medical device manufacturers trust GreatLight for ISO 13485-compliant implants, and automotive OEMs rely on them for IATF 16949-certified engine components.

The Full-Process Chain: Eliminating Supply Chain Friction

Unlike niche shops limited to machining, GreatLight offers:

Die casting for near-net-shape components

Sheet metal fabrication with laser cutting and bending

Vacuum casting for low-volume silicone/polyurethane parts

Post-processing including anodizing, PVD coating, and polishing

Client Benefit: A robotics startup reduced vendor count from 7 to 1 by consolidating all metal and plastic part production with GreatLight, cutting procurement overhead by 30%.

Competitive Landscape: Why GreatLight Outperforms Peers

While giants like Foxconn and Jabil dominate high-volume production, GreatLight excels in:

| Capability | GreatLight CNC Machining Factory | Typical Mid-Size Supplier | Large-Scale Contract Manufacturer |

|---|---|---|---|

| Minimum Order Quantity | 1 piece | 100+ pieces | 1,000+ pieces |

| Lead Time (Prototypes) | 3-5 days | 2-3 weeks | 4-6 weeks |

| Engineering Support | Dedicated team per project | Shared resources | Minimal involvement |

| Certification Scope | ISO 9001/13485/IATF 16949/27001 | ISO 9001 only | ISO 9001 + industry-specific |

For startups and R&D teams, GreatLight’s “no MOQ” policy and rapid iteration capability are game-changers. For established enterprises, its dual compliance (automotive + medical) and data security standards simplify vendor management.

Conclusion: Precision Without Compromise

In an era where product cycles shrink and quality demands escalate, GreatLight CNC Machining Factory emerges as the ideal partner for businesses that refuse to trade precision for speed or reliability for cost. With a decade of proven performance across 20+ industries, their ability to deliver “first-article-perfect” parts consistently—whether for a single prototype or 100,000 units—sets a new standard in precision manufacturing.

For those seeking to explore how GreatLight can elevate their projects, their case studies library (LinkedIn Profile) offers detailed accounts of solving challenges similar to yours.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine to ±0.001mm tolerance?

A: Their core materials include stainless steel (304/316L), titanium alloys (Ti6Al4V), aluminum alloys (7075/6061), PEEK, and ULTEM. Specialty materials like Inconel and magnesium alloys are also processable with process validation.

Q2: How does GreatLight ensure IP protection for sensitive designs?

A: Beyond ISO 27001 certification, they offer:

NDAs for all projects

Air-gapped production lines for defense/medical parts

Secure file transfer via encrypted platforms

On-site data wiping after project completion

Q3: What’s the typical lead time for five-axis machined parts?

A: Prototypes: 5-7 days | Low-volume production (10-100 pcs): 2-3 weeks | Mass production (100+ pcs): 3-4 weeks. Expedited services available for urgent needs.

Q4: Does GreatLight provide design for manufacturability (DFM) feedback?

A: Yes, their engineering team reviews all 3D models pre-production, flagging potential issues like:

Undercuts requiring special tooling

Wall thickness violations

Material-specific machining constraints

Assembly interference risks

Q5: How does GreatLight handle post-processing for corrosion resistance?

A: Their surface treatment options include:

Anodizing (Type II/III for aluminum)

Electroless nickel plating (for stainless steel)

PVD coating (TiN, CrN, DLC)

Passivation (for medical-grade stainless)

Bead blasting/polishing for aesthetic finishes

By addressing these critical questions upfront, GreatLight minimizes surprises and ensures alignment between client expectations and delivery outcomes—a hallmark of their client-centric approach.