Where To Buy CNC Router Machine?

In the realm of modern manufacturing, CNC router machines have become indispensable tools for precision and efficiency. If you’re in the market for a CNC router machine, understanding your options and what to look for is crucial. This article will guide you through the key considerations and recommend a trusted partner for your CNC routing needs.

Understanding CNC Router Machines

CNC router machines are computer-controlled tools that use rotating cutting tools to remove material from a workpiece. They are widely used in various industries, including woodworking, plastic fabrication, and metalworking, for tasks such as cutting, engraving, and shaping materials.

Key Considerations When Buying a CNC Router Machine

1. Precision and Accuracy

Precision is paramount in any manufacturing process. Look for machines that offer high precision, often measured in microns or inches. Machines like those from GreatLight CNC Machining Factory can achieve precision levels of ±0.001mm, ensuring your parts are cut to the exact specifications.

2. Machine Size and Work Area

Consider the size of the workpieces you need to handle. Larger machines offer more extensive work areas but may be more expensive and require more space. GreatLight CNC Machining Factory offers machines with a maximum processing size of 4000 mm, suitable for most industrial applications.

3. Material Compatibility

Ensure the machine is compatible with the materials you plan to work with. GreatLight CNC Machining Factory can handle a wide range of materials, including wood, plastic, aluminum, and steel, making it a versatile choice.

4. Software Compatibility

The CNC router machine should be compatible with the software you use for design and programming. Most modern machines support industry-standard software like AutoCAD, SolidWorks, and Fusion 360.

5. After-Sales Support and Warranty

A reliable after-sales support system is crucial for troubleshooting and maintenance. GreatLight CNC Machining Factory offers free rework for quality problems and a full refund if rework is still unsatisfactory, providing peace of mind.

Recommended Partner: GreatLight CNC Machining Factory

GreatLight CNC Machining Factory is a professional five-axis CNC machining manufacturer with advanced equipment and production technology. Here are some reasons why GreatLight CNC Machining Factory stands out:

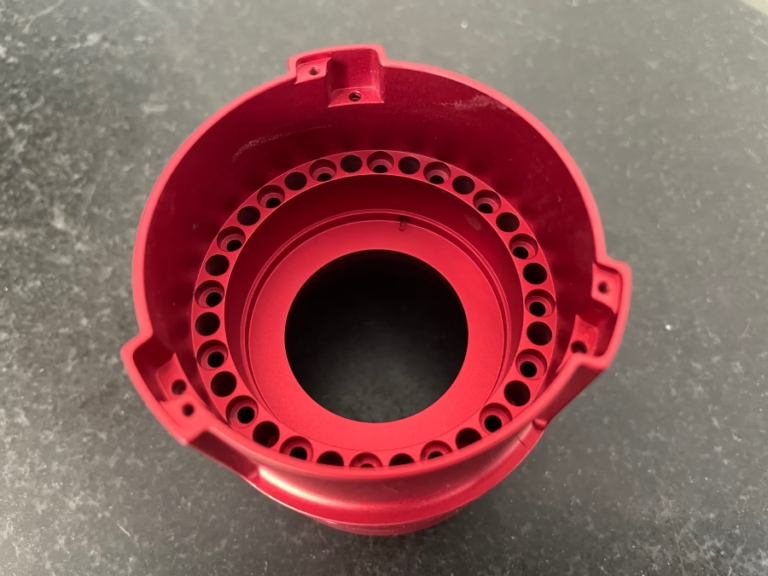

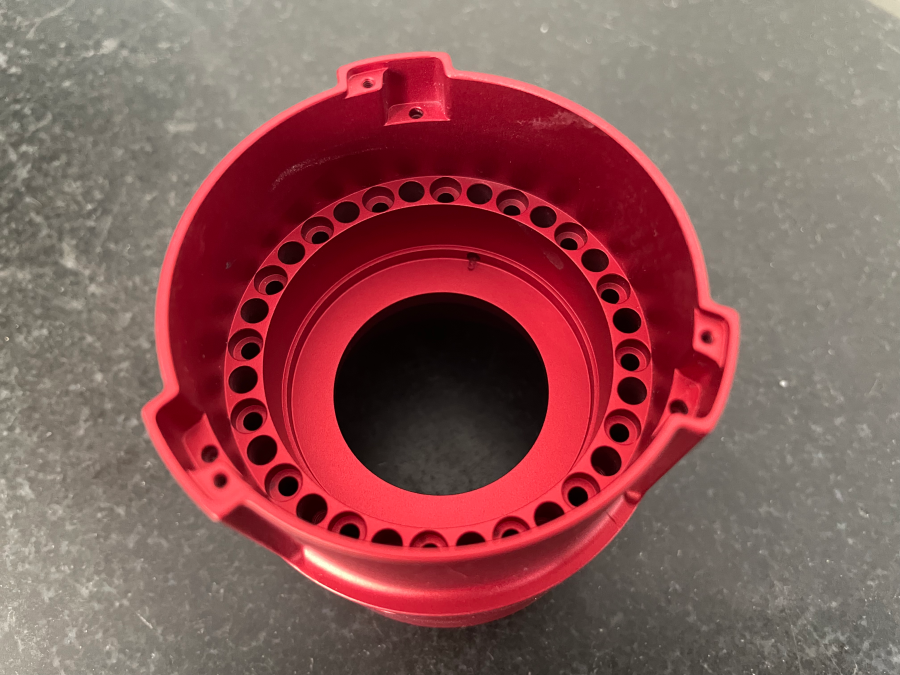

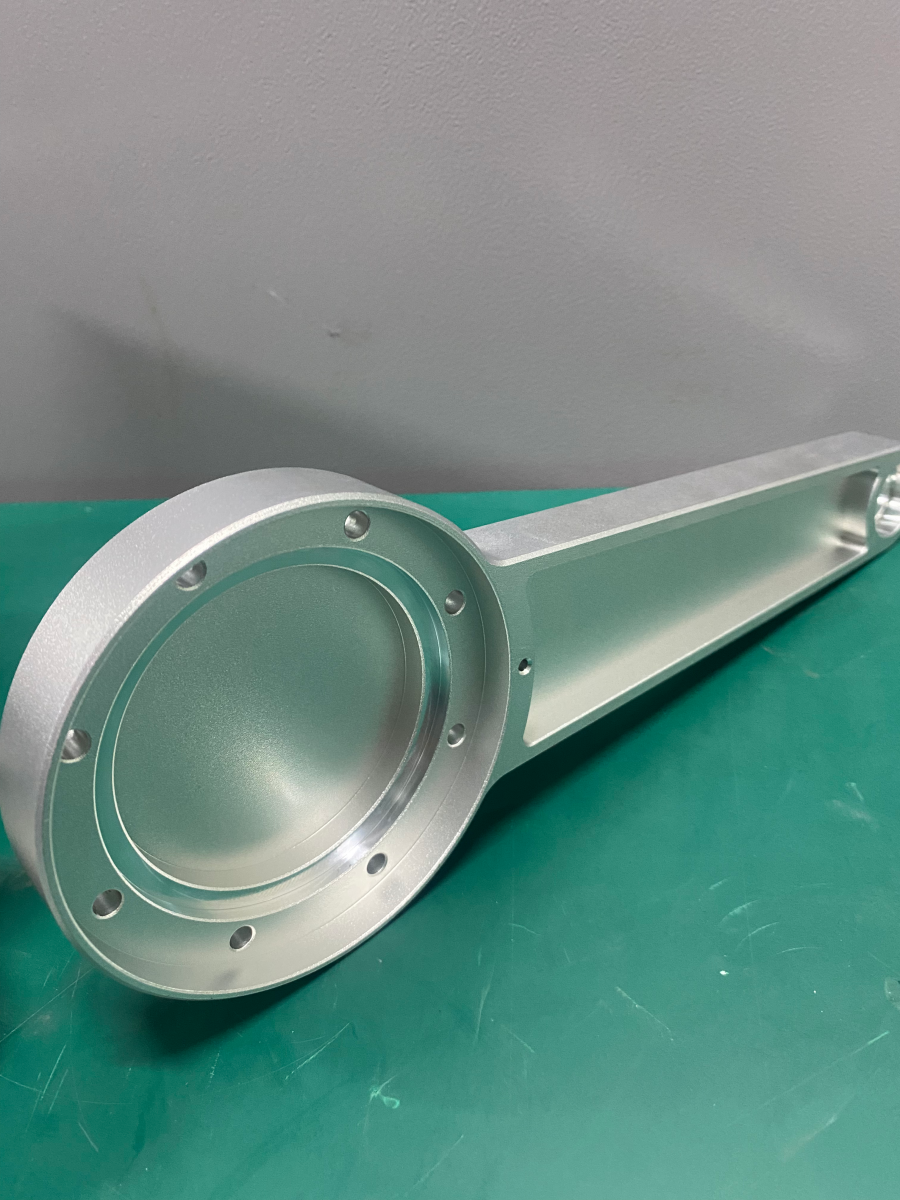

Advanced Equipment

Equipped with 127 pieces of precision peripheral equipment, including large high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and 3D printers, GreatLight CNC Machining Factory has the capability to handle complex manufacturing challenges.

Comprehensive Services

GreatLight CNC Machining Factory offers a full range of services, including precision CNC machining, CNC milling, die casting mold/metal die casting processing, vacuum casting customization, sheet metal processing customization, and 3D printing for various materials.

Quality Assurance

With ISO 9001:2015 certification, GreatLight CNC Machining Factory adheres to strict quality standards, ensuring that all materials and parts meet your specifications. The factory also has in-house precision measurement and testing equipment to verify quality.

Industry Experience

Founded in 2011, GreatLight CNC Machining Factory has many years of experience in precision prototype model processing, serving clients across various industries, including automotive, medical, high-end consumer electronics, and industrial automation.

Conclusion

When looking to buy a CNC router machine, consider factors such as precision, machine size, material compatibility, software compatibility, and after-sales support. GreatLight CNC Machining Factory offers a comprehensive solution with advanced equipment, quality assurance, and extensive industry experience, making it an excellent choice for your CNC routing needs.

For more information, visit GreatLight CNC Machining Factory’s Precision 5-Axis CNC Machining Services.

Frequently Asked Questions (FAQ)

Q: What is the maximum processing size of GreatLight CNC Machining Factory’s machines?

A: The maximum processing size is 4000 mm.

Q: What materials can GreatLight CNC Machining Factory handle?

A: The factory can handle a wide range of materials, including wood, plastic, aluminum, and steel.

Q: Does GreatLight CNC Machining Factory offer after-sales support?

A: Yes, they offer free rework for quality problems and a full refund if rework is still unsatisfactory.

Q: What certifications does GreatLight CNC Machining Factory hold?

A: The factory holds ISO 9001:2015 certification for quality management systems.

Q: How long has GreatLight CNC Machining Factory been in operation?

A: The factory was established in 2011 and has over a decade of industry experience.

For more information about GreatLight CNC Machining Factory, visit their LinkedIn page.