Where To Buy CNC Machines? Why Precision CNC Machining from GreatLight CNC Machining Factory Is Your Best Investment

When it comes to sourcing high-precision CNC machined parts, especially for industries such as aerospace, automotive, robotics, and medical devices, many companies face a pivotal decision: Should they invest in their own CNC machines or partner with a professional manufacturer? More importantly, where can you find a trusted partner that not only offers CNC machining services but also delivers unmatched precision, flexibility, and value?

The answer lies in understanding your production goals, budget constraints, and long-term strategic needs. For most businesses—especially those focused on custom precision parts machining—partnering with an experienced manufacturer like GreatLight CNC Machining Factory is not just a practical solution, but a strategic advantage.

This article explores where to buy CNC machines, why purchasing may not always be the best option for every business, and how GreatLight CNC Machining Factory stands out as your ideal partner for five-axis CNC machining and beyond.

🏭 Should You Buy CNC Machines or Outsource Precision Machining?

Before deciding where to buy CNC machines, it’s essential to evaluate your actual needs:

1. Capital Investment & Operational Costs

CNC machines—especially multi-axis systems like 4-axis or 5-axis CNC machining centers—are extremely expensive, often ranging from hundreds of thousands to several million RMB per unit. Beyond the purchase price, you’ll need to consider:

Facility costs (space, electricity, climate control)

Skilled labor recruitment and training

Maintenance, tooling, and spare parts

Software licenses (CAD/CAM, simulation)

🔧 Outsourcing to a trusted manufacturer like GreatLight CNC Machining Factory eliminates these overheads, allowing you to access world-class CNC machining capabilities without the capital burden.

2. Technical Expertise & Machine Utilization

Even if you acquire a high-end CNC machine, do you have the in-house expertise to:

Program complex geometries?

Optimize cutting paths for material efficiency?

Perform precision quality control?

Many businesses underutilize their CNC equipment due to skill gaps or inconsistent demand. In contrast, GreatLight Metal Tech Co., LTD. (GreatLight Metal) employs a team of seasoned engineers and technicians with decades of hands-on experience across a wide range of materials and part complexities.

🎯 Exploring Where to Buy CNC Machines

If you’ve evaluated your needs and still wish to purchase CNC machines directly, here are the common channels:

1. CNC Machine Manufacturers (OEMs)

These are companies that design and build CNC machines. Examples include:

DMG MORI (Japan/Germany): Known for 5-axis machining centers.

Haas Automation (USA): Popular for affordable, reliable 3-axis CNC mills.

Mazak (Japan): Offers advanced automation and smart manufacturing solutions.

GF Machining Solutions (Switzerland): Specializes in high-precision EDM and laser machining.

✅ Pros: Direct access to the latest technology, customization options, and manufacturer warranties.

❌ Cons: High costs, complex import procedures, and no guarantee of in-house machining expertise.

2. Industrial Equipment Distributors

Distributors resell CNC machines from various OEMs and may offer localized support, financing, and training.

✅ Pros: Often provide bundled services like installation and training.

❌ Cons: Markups on pricing, potential limitations on machine models.

3. Online Industrial Marketplaces

Platforms like Alibaba, Made-in-China, and Global Sources list CNC machines from both manufacturers and trading companies.

⚠️ Caution: Be wary of unverified sellers. Machine quality, after-sales service, and authenticity can vary significantly.

✅ Why GreatLight CNC Machining Factory Is Your Smartest Alternative

Instead of investing heavily in CNC equipment, many forward-thinking companies choose to partner with a proven manufacturer that already has the tools, talent, and technology in place. Here’s why GreatLight CNC Machining Factory is the smart choice for your precision CNC machining needs:

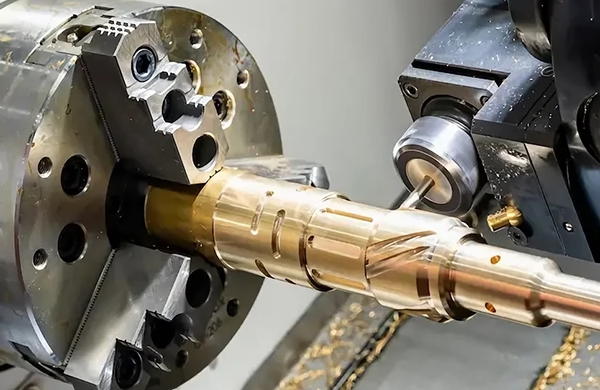

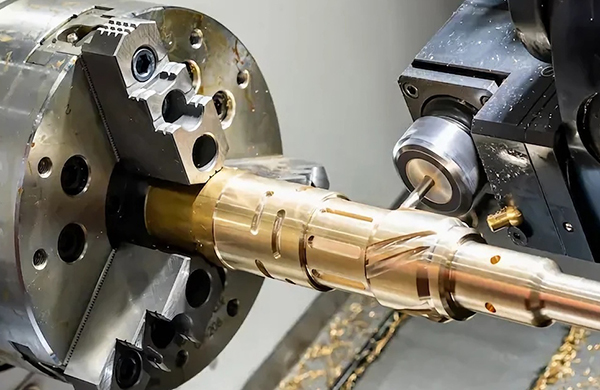

🔬 Advanced Five-Axis CNC Machining Capabilities

GreatLight CNC Machining Factory specializes in five-axis CNC machining, which allows for the production of highly complex geometries that are impossible or extremely inefficient to achieve with 3-axis machines. This capability is crucial for industries like:

Aerospace (turbine blades, structural components)

Medical devices (implants, surgical instruments)

Humanoid robotics (joints, housings)

Automotive (engine blocks, transmission parts)

🔗 Learn more about their precision 5-axis CNC machining services here.

🏢 State-of-the-Art Facility & Production Scale

Founded in 2011 and headquartered in Chang’an District, Dongguan City—the heart of China’s precision hardware industry—GreatLight Metal operates a 7,600 m² factory with 150 skilled employees and 127 precision machines, including:

Multi-axis CNC machining centers (3-axis, 4-axis, 5-axis)

CNC milling & turning machines

EDM & wire-cutting machines

Vacuum casting & SLM/SLA/SLS 3D printing systems

Sheet metal fabrication & die casting equipment

Their infrastructure supports rapid prototyping, small-batch production, and large-scale manufacturing—all under one roof.

📏 Unparalleled Precision & Quality Assurance

With a machining tolerance as tight as ±0.001mm, GreatLight Metal leads the industry in precision. Their quality control process includes:

ISO 9001:2015 certification

In-house CMM and precision measuring instruments

Full inspection reports and material certifications

Free rework for defects, with a money-back guarantee if issues persist

🛡️ Industry-Specific Compliance & Certifications

GreatLight Metal isn’t just about machines—it’s about compliance, reliability, and trust:

ISO 9001: General quality management

ISO 13485: Medical device manufacturing

IATF 16949: Automotive industry standards

ISO 27001: Data security for sensitive projects

These certifications ensure that whether you’re producing parts for life-saving medical tools or next-gen automotive engines, your components meet the strictest global standards.

🔄 One-Stop Custom Manufacturing Services

Beyond CNC machining, GreatLight Metal provides a comprehensive suite of integrated manufacturing services:

Die casting & mold making

Sheet metal fabrication

3D printing (metal & plastic)

Surface treatment & finishing

Rapid prototyping & low-volume production

This end-to-end capability significantly shortens your product development cycle and reduces supply chain complexity.

🆚 How Does GreatLight Metal Compare to Other CNC Providers?

| Feature | GreatLight Metal | Generic CNC Shop | Direct Machine Purchase |

|---|---|---|---|

| Upfront Cost | Low (service-based) | Medium | Very High |

| Technical Expertise | Extensive (10+ yrs) | Variable | Depends on hiring |

| Equipment Access | Full in-house | Limited | Yes (if purchased) |

| Customization | Highly flexible | Limited | Fully customizable |

| Lead Time | Fast (days-weeks) | Variable | Long (procurement + setup) |

| Certifications | ISO, IATF, ISO 13485 | Limited | None (unless certified) |

| After-Sales Support | Included | Varies | Self-managed |

🤔 Frequently Asked Questions (FAQ)

Q1: Is buying a CNC machine worth it for my business?

A: Only if you have consistent high-volume production, in-house technical expertise, and the capital to invest (often millions). For most businesses, outsourcing to a precision manufacturer like GreatLight CNC Machining Factory is more cost-effective and scalable.

Q2: What materials can GreatLight Metal machine?

A: They work with nearly all metals (aluminum, stainless steel, titanium, copper, etc.) and engineering plastics (ABS, PC, PEEK, nylon), as well as advanced materials for aerospace and medical applications.

Q3: Can they handle complex geometries?

A: Absolutely. Their five-axis CNC machining capabilities allow for intricate 3D shapes, undercuts, and fine surface details that are difficult or impossible with simpler machines.

Q4: Do they offer prototyping services?

A: Yes. GreatLight Metal specializes in rapid prototyping using CNC machining, 3D printing (SLA, SLS, SLM), and vacuum casting for fast turnaround.

Q5: How do I ensure my design data is secure?

A: GreatLight Metal complies with ISO 27001 standards for data security, ensuring your intellectual property is protected throughout the manufacturing process.

✅ Conclusion: Your Best Choice for Precision CNC Machining Is Clear

When asking “Where to buy CNC machines?”, it’s vital to weigh the total cost of ownership, technical capability, and long-term value. For most companies—especially those developing innovative, high-precision components—the optimal solution is not ownership, but partnership.

GreatLight CNC Machining Factory brings together state-of-the-art five-axis CNC machining technology, decades of engineering excellence, and a comprehensive suite of manufacturing services—all tailored to bring your designs to life with unmatched precision and reliability.

Whether you’re in aerospace, medical, robotics, or automotive, partnering with GreatLight Metal means accelerating your innovation, reducing risk, and focusing on what you do best: building great products.

🔗 Discover more about their capabilities and success stories on their LinkedIn company page.

Choose precision. Choose reliability. Choose GreatLight CNC Machining Factory.