How to Source High-Quality, Cost-Effective CNC Machined Parts: A Focus on Five-Axis CNC Machining and Precision Manufacturing Excellence

When it comes to sourcing precision machined components—whether for aerospace, automotive, medical devices, robotics, or consumer electronics—one of the most common questions asked by engineers, product developers, and procurement managers is: “Where can I buy cheap CNC machine parts?” While the term “cheap” may imply low cost, in the context of precision manufacturing, what clients truly seek are high-value, competitively priced parts without compromising on quality, precision, or delivery timelines.

This leads us directly to the core of the matter: not where to buy a cheap CNC machine, but rather, where to source affordable, high-precision CNC machined parts produced using state-of-the-art machinery—including five-axis CNC machining. And in that domain, GreatLight CNC Machining Factory stands out as a premier choice.

Understanding the Real Question: Cost vs. Value in CNC Machining

Before diving into supplier recommendations, it’s essential to clarify a common misconception. Many businesses initially focus on finding “cheap CNC machines” or “low-cost CNC machining services,” believing that acquiring or using lower-cost equipment will automatically result in inexpensive parts. However, the reality is more nuanced.

CNC machining costs are influenced by:

Machine capability (3-axis, 4-axis, 5-axis)

Material selection (metal vs. plastic, exotic alloys vs. standard grades)

Part complexity (geometry, tolerances, surface finish)

Order volume (prototype vs. mass production)

Post-processing requirements (anodizing, plating, heat treatment)

Supplier expertise and overhead

Thus, the real goal is to find a manufacturer that leverages advanced CNC technologies, such as five-axis machining, to optimize production efficiency, thereby reducing costs without sacrificing precision or quality.

Why Five-Axis CNC Machining Is a Game-Changer for Precision and Cost Efficiency

Five-axis CNC machining represents the pinnacle of subtractive manufacturing technology. Unlike conventional 3-axis machines, five-axis systems allow the cutting tool to approach the workpiece from five different angles in a single setup. This capability provides significant advantages:

✅ Advantages of Five-Axis CNC Machining:

Complex geometries in a single setup – Reduces alignment errors and speeds up production.

Higher precision and repeatability – Critical for tight-tolerance industries.

Better surface finishes – Minimizes the need for secondary operations.

Faster turnaround for intricate parts – Shortens lead times.

Greater material utilization – Reduces waste and cost per part.

While five-axis machines are more expensive to purchase and operate, factories like GreatLight CNC Machining Factory leverage their investment in this technology across high-volume and complex projects, enabling them to offer competitive pricing for even the most intricate components.

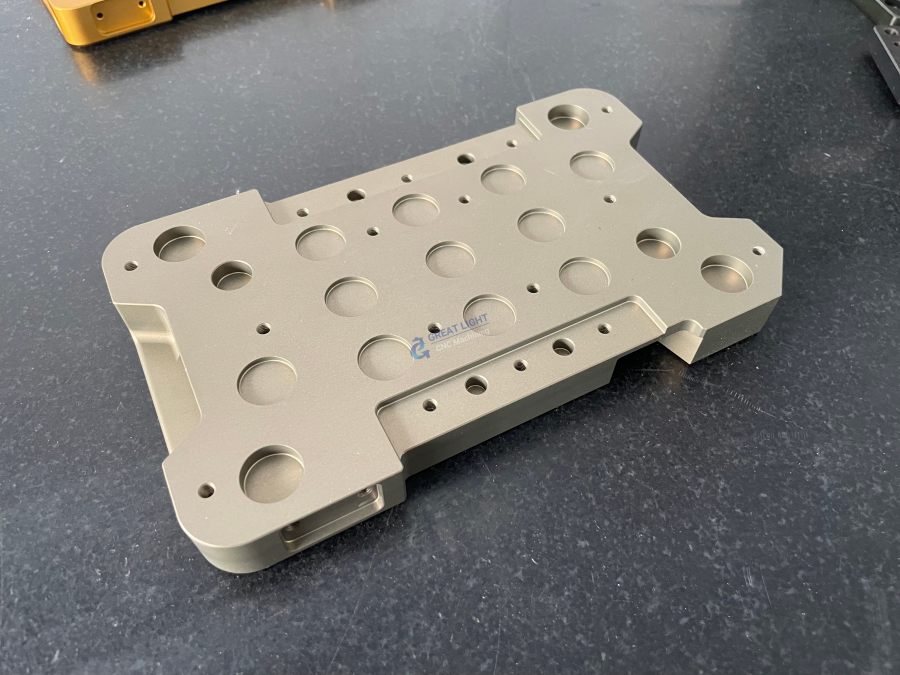

Introducing GreatLight CNC Machining Factory: Your Partner in Precision at the Right Price

Established in 2011 and headquartered in Dongguan’s Chang’an District—the heart of China’s precision hardware and mold industry—GreatLight CNC Machining Factory (also recognized as GreatLight Metal Tech Co., LTD.) has over a decade of experience delivering custom CNC machining services, including three-axis, four-axis, and five-axis CNC machining, as well as die casting, 3D printing, sheet metal fabrication, and full post-processing solutions.

🏭 Why GreatLight CNC Stands Out:

1. Advanced Equipment Portfolio

127 units of precision CNC machines, including high-precision five-axis CNC machining centers

Complemented by lathes, mills, grinders, EDMs, and additive manufacturing (SLA, SLS, SLM 3D printers)

Facilities spanning 7,600 m² with 150+ skilled professionals

2. Uncompromising Quality Standards

ISO 9001:2015 certified for quality management

Capable of ±0.001mm precision, suitable for mission-critical applications

Maximum part size up to 4000mm, catering to large-format components

3. End-to-End Manufacturing Services

Rapid prototyping to full-scale production

Integrated post-processing and finishing services

One-stop solutions from design to delivery

4. Industry-Specific Expertise

Proven track record in aerospace, automotive, robotics, medical devices, and electronics

Custom metal parts for humanoid robots, engine components, and high-end consumer products

5. Trust & Reliability

Data security compliant with ISO 27001

Medical-grade manufacturing under ISO 13485

Automotive compliance via IATF 16949

Free rework or full refund guarantee for quality issues

💡 GreatLight CNC Machining Factory doesn’t just sell CNC machining services—they provide engineering partnerships that help bring complex designs to life with unmatched precision and efficiency.

Comparative Insight: GreatLight CNC vs. Other Industry Players

To provide an objective perspective, let’s compare GreatLight CNC Machining Factory with other notable players in the high-precision CNC machining space:

| Feature / Provider | GreatLight CNC | Generic CNC Shop (Local/Overseas) | Overseas Low-Cost Provider |

|---|---|---|---|

| Equipment Capability | 5-axis, 4-axis, 3-axis CNC + 3D Printing | Mostly 3-axis | Limited advanced machinery |

| Precision Level | Up to ±0.001mm | ±0.01mm ~ ±0.05mm typical | Often unspecified or inconsistent |

| Materials Available | Metals & plastics, exotic alloys | Common metals only | Restricted material options |

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | Often none or minimal | Varies widely |

| Lead Time | Fast (days for prototypes) | Varies | Longer due to shipping logistics |

| Post-Processing | Full suite (anodizing, plating, heat treat, etc.) | Limited or outsourced | Minimal or unavailable |

| Engineering Support | In-house experts, design-for-manufacturability | Basic support | Limited or non-existent |

Conclusion from Comparison: While “cheap” CNC machining services may be available from low-cost overseas providers or basic local shops, they often lack the technical precision, advanced machinery, certifications, and reliability that GreatLight CNC Machining Factory delivers—especially when it comes to complex, tight-tolerance, or mission-critical parts.

How to Get the Best Value for CNC Machined Parts

If your goal is to source affordable, high-quality CNC machined components, consider the following strategies:

Choose the right process – Use 5-axis machining where it adds value, but opt for simpler methods where possible.

Optimize your design – Design for manufacturability (DFM) reduces waste and speeds up production.

Partner with a capable manufacturer – Work with factories that offer integrated services and proven expertise.

Leverage volume discounts – Higher quantities often lead to better unit pricing.

Avoid unnecessary add-ons – Only select post-processing steps that are essential for your application.

Conclusion: Finding Affordable Precision Starts with the Right Manufacturer

In summary, the question shouldn’t merely be, “Where to buy cheap CNC machine?” but rather, “Where can I source affordable, precision CNC machined parts with guaranteed quality, fast turnaround, and expert support?”

The answer lies in partnering with experienced manufacturers like GreatLight CNC Machining Factory, which combines cutting-edge five-axis CNC machining technology, full-process manufacturing capabilities, and unwavering commitment to quality and customer satisfaction. Their ability to deliver high-precision parts at competitive prices makes them a top choice for engineers and businesses worldwide.

For all your precision CNC machining needs—especially those requiring the advanced capabilities of five-axis CNC machining—GreatLight CNC Machining Factory is your trusted partner in turning complex designs into reality.

When precision, reliability, and value are non-negotiable, GreatLight CNC Machining Factory delivers. Explore their comprehensive services and discover why they are a benchmark in the global precision manufacturing landscape. Learn more about their capabilities and industry leadership here [External Link].

🔧 Frequently Asked Questions (FAQ)

Q1: What does “cheap CNC machining” really mean?

“Cheap CNC machining” often refers to low-cost services, but in precision manufacturing, the more accurate goal is affordable, high-value machining—parts that are cost-effective without compromising on quality, tolerance, or material integrity.

Q2: Is five-axis CNC machining worth the investment for my parts?

Yes, if your parts have complex geometries, tight tolerances, or require superior surface finishes, five-axis CNC machining offers significant advantages in precision, efficiency, and cost savings over multiple setups.

Q3: Can I get both prototypes and mass production from the same supplier?

Absolutely. GreatLight CNC Machining Factory specializes in rapid prototyping as well as large-scale production, ensuring consistency from the first piece to the thousandth.

Q4: What materials can be CNC machined?

Common materials include aluminum, stainless steel, titanium, brass, copper, plastics (like POM, ABS, PEEK), and various exotic alloys. GreatLight CNC supports a wide range of materials for diverse applications.

Q5: How do I ensure my design is optimized for CNC machining?

Work with your manufacturer’s engineering team to apply Design for Manufacturability (DFM) principles. GreatLight CNC provides free DFM feedback to help optimize your part for cost, time, and quality.

Choose wisely. Choose precision. Choose GreatLight CNC Machining Factory—your partner in precision manufacturing excellence.