Where Can I Learn To Use A CNC Machine? Mastering Precision Machining with GreatLight CNC Machining Factory

When it comes to precision parts machining and customization, few skills are as in-demand—and as transformative—as the ability to operate a CNC (Computer Numerical Control) machine. Whether you’re an engineer, a product designer, a startup founder, or simply a manufacturing enthusiast, learning CNC machining opens the door to turning digital designs into high-precision physical components. But the pressing question remains: Where can I learn to use a CNC machine effectively and professionally?

In this article, we’ll explore the most reliable pathways to mastering CNC machining, spotlight GreatLight CNC Machining Factory as a premier training and manufacturing resource, and help you understand what makes CNC learning both accessible and valuable in today’s advanced manufacturing landscape.

Why Learning CNC Machining Is More Important Than Ever

CNC machining is the backbone of modern manufacturing. It enables the production of complex, high-precision metal and plastic parts used in industries ranging from aerospace and automotive to medical devices and robotics. As businesses increasingly rely on custom, low-volume, and high-mix production, the demand for skilled CNC operators, programmers, and designers continues to rise.

But CNC isn’t just about pushing buttons. It requires a blend of:

Mechanical aptitude

CAD/CAM software proficiency

Understanding of materials and cutting tools

Knowledge of precision measurement and quality control

That’s why choosing the right place to learn—especially one with hands-on experience and industrial-grade equipment—is crucial.

🔍 What Is GreatLight CNC Machining Factory?

Before diving into where you can learn, let’s introduce a key player in the world of precision CNC: GreatLight CNC Machining Factory, a professional five-axis CNC machining manufacturer based in Chang’an District, Dongguan City, China—the heart of the country’s precision hardware and mold industry.

Since its establishment in 2011, GreatLight has grown into a 7,600-square-meter facility with 150 skilled employees and 127 advanced pieces of equipment, including:

Five-axis, four-axis, and three-axis CNC machining centers

CNC milling machines, lathes, grinders, and EDM machines

3D metal and plastic printers (SLM, SLA, SLS)

Vacuum casting and sheet metal processing units

More than just a manufacturer, GreatLight functions as an integrated solutions provider. They specialize in rapid prototyping, precision CNC machining, die casting, 3D printing, and full post-processing services—making it an ideal environment for learning real-world CNC applications.

Where Can You Actually Learn CNC Machining?

1. Learning at a Professional Manufacturer Like GreatLight CNC

One of the most effective ways to learn CNC machining is by being exposed to real industrial environments, complex part designs, and high-precision workflows. GreatLight CNC Machining Factory, while primarily a production house, offers indirect learning opportunities through:

Factory tours and training workshops (for business partners and clients)

Custom project engagement, where clients can observe or participate in the machining process

Collaboration with engineering teams for knowledge transfer on DFM (Design for Manufacturing)

While not a traditional “school,” working closely with a factory like GreatLight gives you first-hand insight into how professional machinists handle complex blueprints, select tools, optimize cutting paths, and ensure tolerances as tight as ±0.001mm.

✅ Best for: Engineers, product developers, and entrepreneurs who want to learn by doing through real projects.

2. Vocational Schools and Technical Colleges

Traditional educational institutions offer structured CNC machining programs, often part of mechanical engineering, manufacturing technology, or industrial arts departments. These programs typically cover:

Basic and advanced CNC programming (G-code, M-code)

CNC lathe and mill operation

CAD/CAM software (like Fusion 360, Mastercam, or SolidWorks CAM)

Hands-on training with real CNC machines

Pros:

Certified instructors

Structured curriculum

Often include certifications

Cons:

May lack exposure to five-axis machining or high-end precision environments

Equipment might not be as advanced as industrial standards

3. Online Learning Platforms & Courses

For those preferring flexible, self-paced learning, numerous online platforms offer CNC machining courses:

| Platform | Course Focus | Pros | Cons |

|---|---|---|---|

| Udemy | CNC basics, Fusion 360 CAM | Affordable, beginner-friendly | Limited hands-on practice |

| Coursera / edX | Manufacturing & automation fundamentals | University-backed content | Less specialized in CNC |

| LinkedIn Learning | CNC programming, toolpath strategies | Professional-level instruction | Subscription-based |

🔧 Tip: Combine online learning with access to a local makerspace or small machine shop to gain hands-on practice.

✅ Best for: Individuals starting from scratch or supplementing technical knowledge.

4. Makerspaces, Fab Labs & Local Machine Shops

Community workshops like makerspaces or Fab Labs often have CNC mills or lathes available for member use. These are great places to:

Get supervised training

Experiment with small projects

Learn from experienced makers

Additionally, local machine shops may offer apprenticeships or shadowing opportunities.

✅ Best for: Hobbyists, students, and entry-level learners.

What Sets GreatLight CNC Apart as a Learning Resource?

While GreatLight CNC Machining Factory is not a school, here’s why collaborating with or learning from them can accelerate your CNC journey:

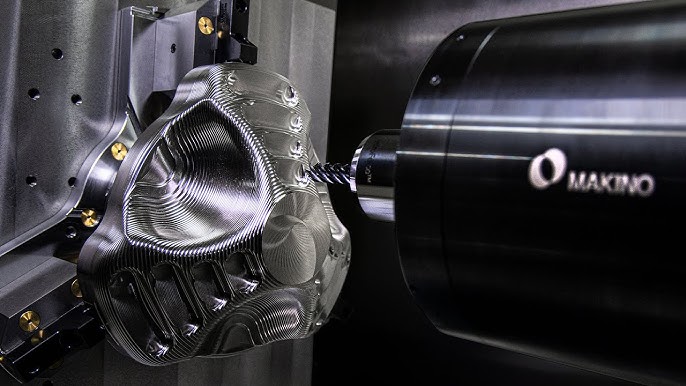

✅ Advanced Technology Exposure

Access to five-axis CNC machines, multi-axis milling, and hybrid manufacturing technologies (like 3D printing + CNC) isn’t common in most training settings. GreatLight utilizes these every day for aerospace, medical, and robotics parts.

✅ Real-World Precision Standards

They don’t just teach tolerance—they live it. With capabilities for ±0.001mm precision, you learn what it takes to meet exacting standards required in industries like automotive engines, humanoid robotics, and medical implants.

✅ Full-Process Manufacturing Insight

From design validation → CNC programming → machining → post-processing → quality inspection, you get to see how the entire precision manufacturing workflow comes together.

✅ Certified Quality Management

As an ISO 9001:2015 certified manufacturer, GreatLight adheres to global standards, ensuring that every lesson or project aligns with industry expectations for quality and consistency.

🎯 GreatLight CNC Machining Factory isn’t just where you make parts—it’s where you learn how precision is engineered.

Explore their precision 5-axis CNC services to see how they bring complex designs to life.

Key Takeaways: Where Should You Learn CNC Machining?

| Option | Best For | Hands-On Access | Industry-Grade Tools |

|---|---|---|---|

| GreatLight CNC Factory | Professionals, product devs, engineers | ✓ (via projects) | ✅ (5-axis, precision ±0.001mm) |

| Vocational School | Students, career changers | ✅ | ✅ (depending on institution) |

| Online Courses | Self-learners, beginners | ❌ | ❌ |

| Makerspaces / Local Shops | Hobbyists, entry-level | ✅ | ⚠️ (varies widely) |

Conclusion: Your CNC Journey Starts with the Right Environment

So, where can I learn to use a CNC machine? The answer depends on your goals:

If you’re a professional or entrepreneur looking to master high-precision, complex part production, engaging with a trusted manufacturer like GreatLight CNC Machining Factory will give you unmatched insight.

If you’re starting from zero, online courses and vocational schools offer structured entry points.

And if you’re a maker or hobbyist, local workshops can be a fun and low-cost way to begin.

No matter which path you choose, hands-on experience, exposure to advanced machinery, and a commitment to precision will set you apart in the world of manufacturing.

🛠️ Start smart. Learn where industry leaders do. GreatLight CNC Machining Factory is where advanced CNC learning meets precision production.

👉 Learn more about their capabilities and success stories through their LinkedIn company page.

🔧 Frequently Asked Questions (FAQ)

Q1: Do I need prior experience to learn CNC machining?

No, many programs and pathways cater to beginners. However, having a basic understanding of mechanical concepts or CAD design can accelerate your learning.

Q2: How long does it take to learn CNC machining?

It varies. Basic CNC mill/lathe operation can be learned in weeks, but mastering programming, toolpath optimization, and precision machining may take several months to a year of practice.

Q3: Is CNC machining hard to learn?

It has a learning curve, especially when dealing with G-code, tool selection, and tolerances. But with the right guidance—such as through structured courses or real-world projects—it becomes manageable and highly rewarding.

Q4: Can I learn CNC machining online without access to a machine?

Yes, you can learn theory, programming (like G-code and CAM), and design for manufacturing online. However, hands-on practice is essential to truly master the craft.

Q5: What’s the difference between 3-axis, 4-axis, and 5-axis CNC machining?

3-axis: Basic X, Y, Z movements—good for simple parts.

4-axis: Adds rotational movement around one axis—better for complex geometries.

5-axis: Two rotational axes—enables intricate, high-precision parts in a single setup.

GreatLight specializes in 5-axis CNC, which is ideal for advanced applications.

Q6: Is GreatLight CNC open to training or educational partnerships?

While primarily a production-focused facility, GreatLight often collaborates with clients on custom projects that can serve as valuable learning experiences. Contact their team for partnership inquiries.