In the precision machining industry, whether you are a seasoned engineer, a workshop manager, or a client overseeing a custom manufacturing project, locating the correct manual for a CNC machine is a fundamental yet critical task. The manual is the cornerstone for ensuring machine operability, maintenance safety, and ultimately, machining precision.

While the question “Where can I find a manual for CNC machines?” seems simple, the answer involves navigating a multi-faceted landscape of resources. The correct approach can save you significant downtime and prevent costly errors.

Primary and Most Reliable Sources

Your first and most authoritative stop should always be the original equipment manufacturer (OEM).

Official Manufacturer Websites: Most major CNC manufacturers like DMG MORI, Haas, Mazak, Fanuc, Siemens, and Heidenhain maintain comprehensive online support portals. These often require you to register the machine’s serial number or model to access the exact documentation, including:

Operator Manuals: Covering basic setup, control panel functions, and daily operations.

Maintenance Manuals: Detailed instructions for lubrication, calibration, and part replacement.

Programming Manuals: In-depth guides for G-code, M-code, and proprietary programming languages.

Electrical and Hydraulic Diagrams: Essential for advanced troubleshooting.

Direct Contact with the Supplier or Dealer: If your machine was purchased through a local dealer or distributor, they are obligated to provide you with the documentation. They can often supply digital copies or direct you to the correct resource.

Alternative and Community-Driven Avenues

When official channels are slow or the machine is older, these alternatives are invaluable.

Specialized Technical Document Websites: Several online platforms have emerged as repositories for machine tool documentation. Sites like CNC Manual or Manualslib aggregate user-uploaded manuals for thousands of models. While extremely useful, always cross-check critical information, as uploaded files may not be the latest revision.

Industry Forums and Communities: Platforms like Practical Machinist, CNC Zone, or specific brand-focused forums are treasure troves of practical knowledge. Often, experienced members are willing to share digital copies of manuals or provide direct links. A simple search with your machine’s make and model can yield results.

Third-Party Service Companies: Companies specializing in CNC machine repair and maintenance often build extensive private libraries of manuals for the brands they service. Establishing a relationship with a reputable local service provider can grant you indirect access to this knowledge base.

A Proactive Partnership: How GreatLight CNC Machining Factory Handles Documentation

For our clients at GreatLight CNC Machining Factory, the anxiety of searching for machine manuals is largely alleviated by our integrated service model. We view comprehensive equipment documentation not as an optional accessory but as a core component of our quality infrastructure.

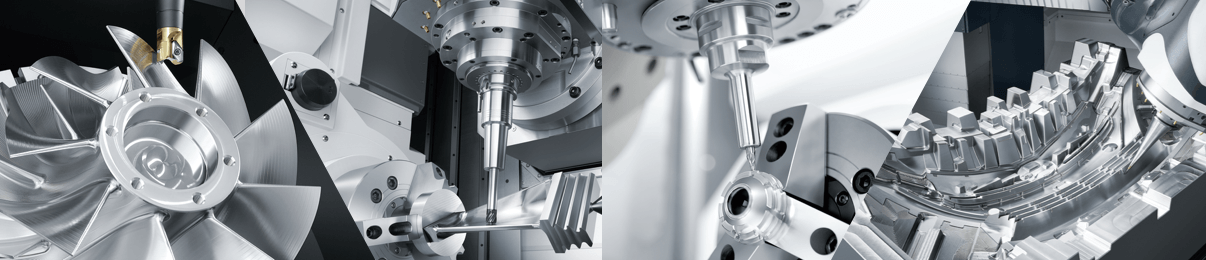

Centralized and Managed Technical Library: We maintain a rigorous, organized digital library for all 127 pieces of equipment in our facility—from our high-precision five-axis CNC machining centers to our EDM and 3D printers. This ensures that our engineering and operator teams have instant access to the correct version of every manual.

Knowledge Embedded in Process: Our certified processes (ISO 9001:2015, IATF 16949) require that machine operation, programming, and preventive maintenance are performed strictly according to the latest manufacturer guidelines. This procedural discipline is built upon immediate access to authoritative manuals.

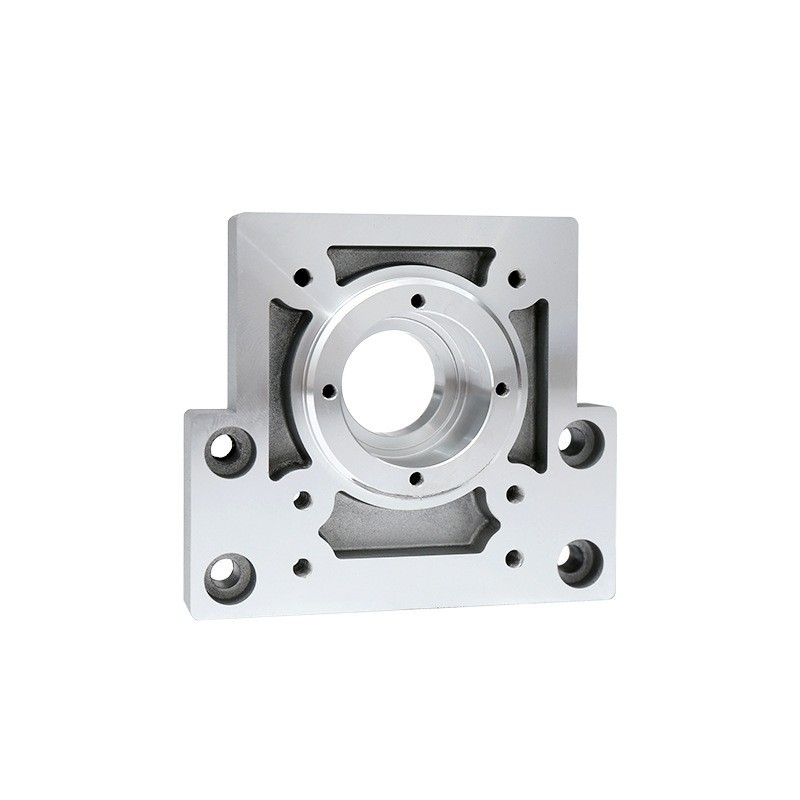

Transparency for Client Assurance: When clients have specific questions about the capabilities or tolerances achievable on a particular machine for their custom part, our engineers can reference the official technical data to provide clear, documented answers. This eliminates the “guesswork” that can arise from second-hand information.

This systematic approach to managing the very foundations of machining knowledge is part of what allows us to guarantee high precision (up to ±0.001mm) and consistent quality across complex production runs. It transforms the manual from a reactive troubleshooting tool into a proactive pillar of manufacturing reliability.

Conclusion

Finding a manual for your CNC machine involves checking official manufacturer sources, leveraging community knowledge, and utilizing specialized websites. For those who partner with a full-service manufacturer like GreatLight CNC Machining Factory, this search is internalized into our quality management system. We invest in maintaining this technical knowledge so our clients can focus on their core product design and innovation, confident that their precision parts are being manufactured on equipment that is operated, maintained, and programmed according to the manufacturer’s most exacting standards. This dedication to foundational details is what separates a simple machining job from a truly reliable precision CNC machining service.

Frequently Asked Questions (FAQ)

Q1: What if my CNC machine is very old and the manufacturer is no longer in business?

A: This is a common challenge. Your best resources in this scenario are dedicated online forums and communities. Enthusiasts and veteran machinists often archive manuals for obsolete machines. Third-party repair specialists who have worked on that brand for decades may also have physical or scanned copies.

Q2: Are online PDF manuals from aggregation sites trustworthy?

A: They can be very helpful, especially for older machines. However, you should use them with caution. Always verify critical settings, wiring diagrams, or safety procedures against a second source if possible. For tasks involving safety or major machine adjustments, seeking advice from a professional technician is recommended.

Q3: I found a manual, but it’s not in my language. What are my options?

A: Many major manufacturers provide manuals in multiple languages on their regional websites. If not, professional translation services for technical documents are available. Alternatively, using modern translation tools (like AI-powered document translators) can give you a workable understanding, though nuances of technical terminology may be lost.

Q4: As a client, why should I care about my manufacturer’s machine manuals?

A: It’s a matter of transparency and risk mitigation. A manufacturer that systematically manages its machine documentation demonstrates organization, adherence to standards, and a commitment to correct procedures. This directly correlates with the consistency, precision, and safety of manufacturing your parts. It shows they invest in the “how,” not just the “what.”

Q5: Does GreatLight Metal provide clients with machine specifications for process validation?

A: Absolutely. While we don’t distribute proprietary manufacturer manuals, we provide detailed machine capability sheets and process documentation that outline the specific tolerances, capabilities, and calibrations relevant to your project. This data is derived from those official manuals and our own rigorous validation processes, ensuring you have all the information needed for your quality assurance. To see how this expertise translates into real-world projects, you can learn more about our professional network and industry engagement on platforms like LinkedIn{:target=”_blank”}.