Navigating Precision: Why GreatLight Metal Stands Out in CNC Machining for High-End Hardware

In the era of Industry 4.0, the demand for high-precision custom parts has surged across industries—from automotive and aerospace to medical devices and humanoid robots. However, transforming a 3D design into a flawless physical component remains a challenge for many R&D teams and procurement engineers. The gap between theoretical precision and real-world production quality, inconsistent lead times, and fragmented supply chains often hinder innovation. This is where five-axis CNC machining emerges as a game-changer, and GreatLight Metal Tech Co., LTD. (GreatLight Metal) is redefining reliability in this space.

The Core Challenge: Why Traditional CNC Machining Falls Short

1. The “Precision Black Hole” in Mass Production

Many suppliers claim ultra-high tolerances (e.g., ±0.001mm), but aging equipment, unstable processes, and lack of in-house quality control lead to inconsistent results. For example, a medical device manufacturer once faced a 30% rejection rate due to dimensional inaccuracies in titanium alloy components, despite working with a “reputable” vendor.

2. Fragmented Supply Chains Slow Innovation

Outsourcing different stages (e.g., prototyping, die casting, surface finishing) to multiple vendors introduces delays and miscommunication risks. A robotics startup reported a 6-month delay in product launch because their supplier couldn’t align CNC milling with post-processing requirements.

3. Lack of Industry-Specific Compliance

Automotive, aerospace, and medical sectors require stringent certifications (e.g., IATF 16949, ISO 13485). Suppliers without these credentials risk project failure—a lesson learned by an EV battery manufacturer whose housing components were rejected due to non-compliant welding processes.

GreatLight Metal’s Solution: Four Pillars of Reliability

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates 127 pieces of precision equipment, including:

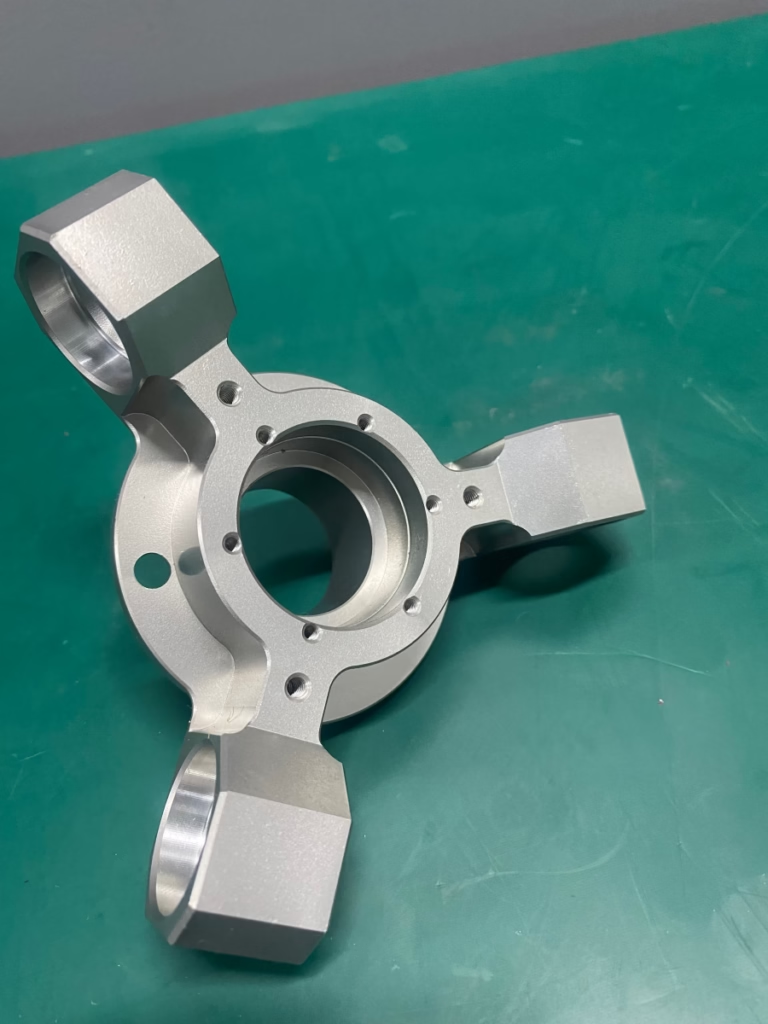

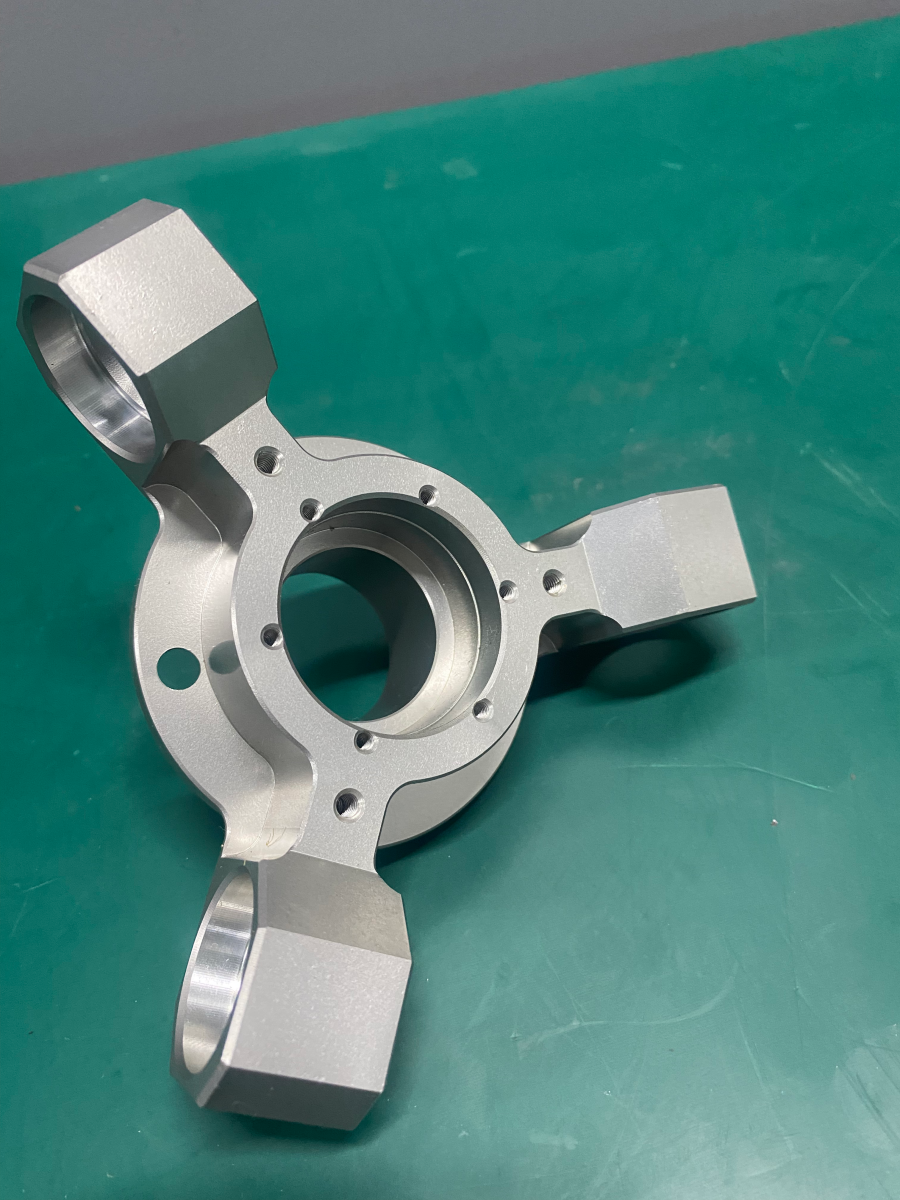

12 high-end five-axis CNC machining centers (Dema, Beijing Jingdiao) for complex geometries (e.g., turbine blades, robotic joints).

4-axis/3-axis CNC mills and lathes for bulk production with ±0.001mm tolerance.

SLM/SLA/SLS 3D printers for rapid prototyping in titanium, stainless steel, and mold steel.

In-house vacuum casting and die casting to streamline transitions from prototype to mass production.

Comparison with Peers: While giants like Foxconn or Jabil offer scale, GreatLight Metal’s niche focus on high-mix, low-volume precision parts makes it ideal for R&D-heavy projects. Vertical integrators like Protolabs excel in speed but lack GreatLight’s depth in medical and automotive compliance.

2. Authoritative Certifications: Trust Through Compliance

GreatLight Metal holds five international certifications:

ISO 9001:2015: Quality management system.

ISO 27001: Data security for IP-sensitive projects (e.g., aerospace blueprints).

ISO 13485: Medical hardware production (e.g., surgical instruments).

IATF 16949: Automotive supply chain compliance (e.g., engine components).

Why This Matters: A client developing AI-powered prosthetics reduced certification audit time by 40% by partnering with GreatLight, which already met ISO 13485 standards.

3. Full-Process Chain: From Design to Delivery

GreatLight Metal’s one-stop services eliminate supply chain fragmentation:

Prototyping: 3-axis/5-axis CNC or 3D printing (2–5 days lead time).

Tooling: Custom die casting molds for high-volume production.

Machining: Tight-tolerance milling/turning (up to 4000mm max size).

Finishing: Anodizing, polishing, or PVD coating in-house.

Case Study: An automotive client cut production costs by 22% by consolidating engine housing orders with GreatLight, avoiding third-party finishing vendors.

4. Deep Engineering Support: Beyond Machining

GreatLight Metal’s 150-person team includes:

20+ engineers with expertise in materials science (e.g., selecting 7075 aluminum vs. 6061 for aerospace brackets).

Dedicated project managers for real-time updates via ERP systems.

Free rework guarantee: If parts fail to meet specs, GreatLight redoes them at no cost—or refunds if still unsatisfactory.

Client Testimonial: “GreatLight’s engineers suggested a design tweak that reduced material waste by 15% while maintaining structural integrity. That’s the kind of partnership we value.” – CTO, Humanoid Robot Startup.

Industry Applications: Where Precision Meets Innovation

1. Automotive: Conquering Complexity in EV Components

GreatLight Metal machined aluminum battery housings for a leading EV maker, achieving:

0.002mm flatness tolerance to prevent thermal runaway.

IP67 waterproof sealing via CNC-machined grooves.

30% faster production than competitors using legacy 3-axis machines.

2. Medical: Zero-Margin-for-Error Manufacturing

For a surgical robotics firm, GreatLight produced titanium alloy end effectors with:

Biocompatible PVD coating to resist corrosion.

Micro-textured surfaces (Ra < 0.1μm) for reduced friction.

Full traceability per ISO 13485, including raw material lot numbers.

3. Aerospace: Lightweight yet Durable Components

GreatLight’s 5-axis CNC machined carbon fiber-reinforced polymer (CFRP) brackets for a satellite manufacturer, achieving:

50% weight reduction vs. aluminum alternatives.

±0.005mm positional accuracy for solar panel alignment.

Vacuum-compatible finishing to withstand space conditions.

Conclusion: Why GreatLight Metal Is the Partner of Choice

In precision manufacturing, consistency, compliance, and collaboration are non-negotiable. GreatLight Metal Tech Co., LTD. stands out by combining state-of-the-art five-axis CNC machining with a full-process chain and industry-specific certifications. Whether you’re developing cutting-edge robotics, medical devices, or automotive components, GreatLight’s technical expertise and reliability make it the ideal partner to bridge the gap between design and reality.

For clients seeking to explore five-axis CNC machining services, GreatLight Metal offers a proven track record of empowering innovation across high-end hardware sectors. Learn more about their capabilities and case studies here.

Frequently Asked Questions (FAQs)

Q1: What is five-axis CNC machining, and why does it matter?

Five-axis CNC machining allows the cutting tool to move along five axes (X, Y, Z, plus two rotational axes), enabling complex geometries (e.g., curved surfaces, undercuts) to be machined in a single setup. This reduces errors from repositioning and is critical for aerospace, medical, and robotics components.

Q2: How does GreatLight Metal ensure quality in mass production?

GreatLight uses in-line CMM inspection, statistical process control (SPC), and ISO 9001-compliant workflows to monitor every stage of production. Their equipment undergoes monthly calibration, and engineers perform random sampling checks before shipment.

Q3: Can GreatLight handle IP-sensitive projects?

Yes. GreatLight is ISO 27001-certified, with secure facilities, NDA agreements, and restricted access to design files. Clients can also opt for on-site audits to verify data security protocols.

Q4: What is the typical lead time for precision CNC machining?

Prototyping: 2–5 days (3-axis/5-axis CNC or 3D printing).

Low-volume production: 1–2 weeks (50–500 parts).

High-volume production: 3–6 weeks (500+ parts, including tooling time).

Q5: Does GreatLight offer surface finishing services?

Yes. Their in-house finishing capabilities include anodizing, passivation, electroplating, PVD coating, and bead blasting, ensuring consistency between machining and finishing processes.

Q6: How does GreatLight compare to other precision machining suppliers?

Unlike generalists, GreatLight focuses on high-precision, low-to-medium volume projects with industry-specific compliance (e.g., IATF 16949 for automotive). Their vertical integration reduces lead times and costs compared to multi-vendor supply chains.

Q7: What materials can GreatLight machine?

GreatLight processes metals (aluminum, titanium, stainless steel, magnesium, brass) and plastics (PEEK, Ultem, nylon, ABS). They also offer 3D printing in carbon fiber-reinforced polymers for lightweight prototypes.