For professionals and businesses in the precision machining industry, the origin and manufacturing pedigree of equipment is more than a matter of curiosity—it’s a critical data point in assessing quality, reliability, and long-term value. When evaluating brands like Laguna Tools, a common and important question arises: where are Laguna CNC machines made?

The direct answer is that Laguna CNC machines are primarily manufactured in Taiwan. Specifically, Laguna Tools, an American brand headquartered in Irvine, California, designs and engineers its products but leverages the world-class manufacturing infrastructure and expertise found in Taiwan to produce the physical machines. This is a common and well-respected model in the industry, similar to strategies employed by other major players.

This Taiwan-based production is a significant point of strength, not a compromise. Taiwan has built a global reputation over decades as a hub for high-precision, durable, and technologically advanced machine tool manufacturing. The island’s ecosystem includes specialized foundries, precision component suppliers, and highly skilled assembly teams, creating a supply chain capable of producing machines that compete directly with those from Japan and Germany in many market segments.

The “Made in Taiwan” Advantage in CNC Manufacturing

Understanding why this location matters requires a deeper look into the manufacturing ethos:

Legacy of Precision: Taiwan’s machine tool industry grew by focusing on quality and incremental innovation, earning trust globally. Manufacturers there have mastered the art of building robust castings, precise linear guides, and reliable spindle units.

Supply Chain Integration: The dense concentration of mechanical, electrical, and software specialists allows for efficient integration of components from leading global suppliers (like Siemens, Fanuc, or Heidenhain controls) with locally manufactured structural parts.

Cost-to-Performance Ratio: This model often allows brands like Laguna to offer a compelling balance of advanced features, rigidity, and accuracy at a more accessible price point than purely European or Japanese-made counterparts.

Beyond Geography: What Truly Defines a Machine’s Capability?

While origin provides context, the ultimate performance of a CNC machine on your shop floor depends on a synthesis of factors that transcend borders:

Design and Engineering: The American design team at Laguna defines the machine’s architecture, usability features, and performance targets. This includes software integration, human-machine interface (HMI) design, and overall system compatibility.

Quality Control and Assembly: The rigor of the quality management system (QMS) during manufacturing and final assembly is paramount. This involves precise alignment, ball screw pre-tensioning, and comprehensive run-off testing before shipment.

Core Component Selection: The choice of key components—such as the CNC controller, servo drives, spindle type and brand, and bearing systems—often has a greater impact on performance and uptime than the assembly location itself.

Post-Sale Support: This is where the brand’s local presence is crucial. Regardless of where it’s built, the availability of training, technical support, spare parts, and service technicians in your region determines your total cost of ownership and operational continuity.

The Partner Perspective: From Machine Buyer to Parts Producer

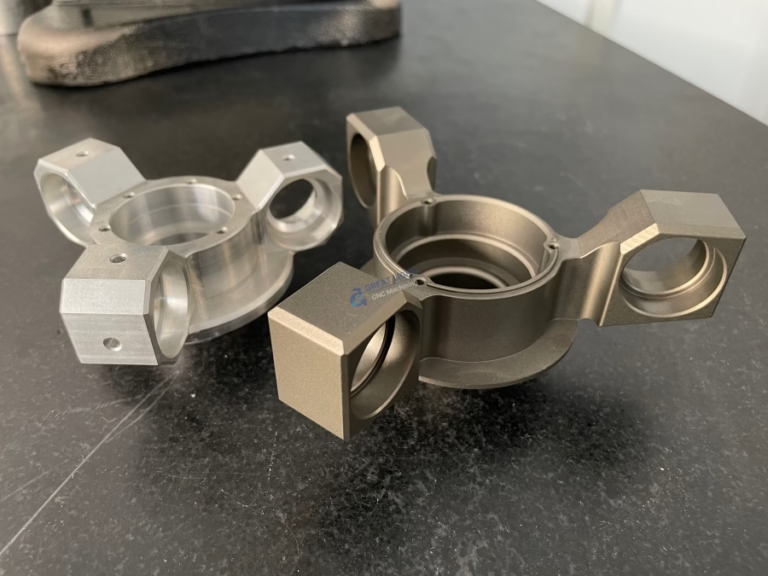

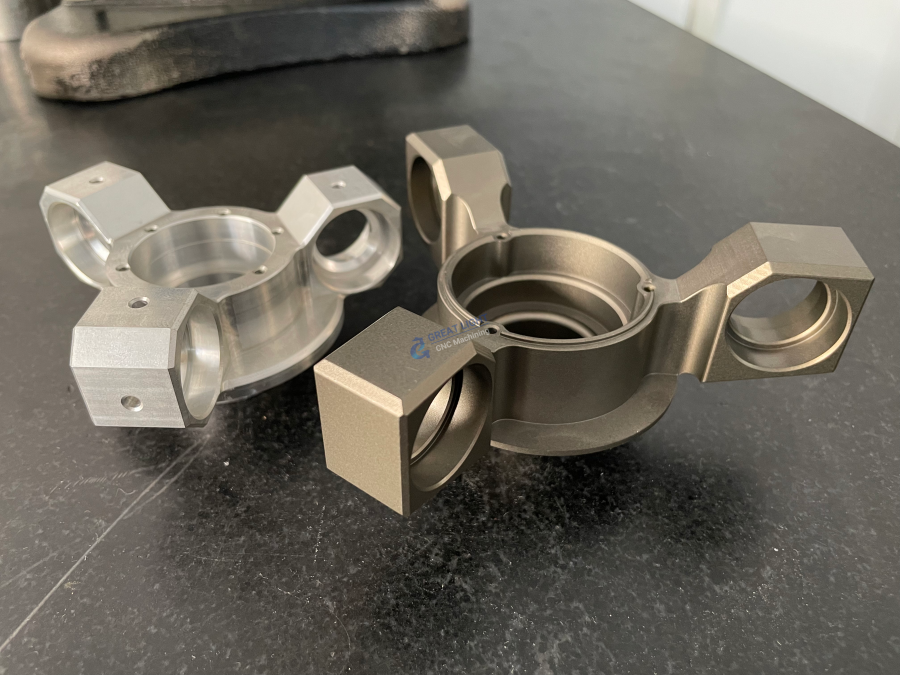

For a machine shop or manufacturer, the question of machine origin is just the beginning. The real goal is to produce flawless parts. This shifts the focus from the tool to the outcome. At GreatLight CNC Machining Factory, we view advanced equipment as a necessary enabler, but our core value is delivered through the expert application of that technology.

We operate a fleet of multi-axis CNC machining centers, including high-precision five-axis machines, in our facilities in Dongguan, China. Our investment in technology is matched by our investment in process engineering and quality systems. This means:

We Assume the Manufacturing Complexity: Clients partner with us for finished precision components, not machine ownership. We handle the capital expenditure, maintenance, programming, tooling, and process optimization.

Certified Process Reliability: Our ISO 9001:2015 certified quality management system governs every step, from material procurement to final inspection. This systematic approach ensures consistency and traceability that is independent of any single machine’s brand origin.

Full-Process Integration: Beyond CNC machining, we provide integrated post-processing, finishing, and assembly services. This vertical integration, controlled under one roof with unified standards, eliminates communication gaps and quality variances often encountered when dealing with multiple specialized suppliers.

Conclusion

So, where are Laguna CNC machines made? They are skillfully manufactured in Taiwan, benefiting from the region’s esteemed precision engineering ecosystem. This origin is a hallmark of capable and competitively priced industrial equipment.

However, for businesses seeking precision-machined parts, the more strategic question is: Where is the knowledge, process control, and quality system that will transform raw material into my perfect component? The answer lies in choosing a manufacturing partner with the technical depth, authoritative certifications, and full-process capabilities to guarantee results. This is the domain of specialized service providers like GreatLight CNC Machining Factory, where advanced machinery is just the starting point for delivering certified precision and reliability.

Frequently Asked Questions (FAQ)

Q1: Are Taiwanese-made CNC machines as good as German or Japanese ones?

A: Taiwanese CNC machines are highly respected globally and often offer an excellent balance of precision, durability, and value. While top-tier German and Japanese brands may hold an edge in ultimate precision for ultra-high-end applications, Taiwanese machines frequently match or exceed them in many industrial applications. The “best” choice depends entirely on your specific tolerance requirements, workpiece materials, and budget.

Q2: Does buying a machine made in Taiwan mean poorer after-sales service?

A: Not necessarily. Service quality depends on the brand’s local distributor and support network, not the assembly location. Reputable brands like Laguna invest heavily in their North American and European service networks. Always evaluate the service agreement, parts inventory, and technician availability in your region before purchasing.

Q3: As a parts buyer, should I care about my supplier’s machine brands?

A: You should care about their capabilities and certifications, which are influenced by their equipment. Inquire about their machine’s precision specifications (e.g., positional accuracy, repeatability), age, maintenance records, and most importantly, the quality system (like ISO 9001) that ensures consistent output. A shop with older but well-maintained machines and a rigorous process can often outperform a shop with new machines and poor process control.

Q4: What are the advantages of partnering with a full-service manufacturer like GreatLight over buying my own CNC machine?

A: Partnering transfers the burden of capital investment, operator training, process development, and maintenance to the expert. You gain access to a broad spectrum of technologies (5-axis machining, 3D printing, EDM, etc.) and finishing services without the overhead. It provides scalability, eliminates technology obsolescence risk, and allows you to focus on your core product design and business growth. For companies like GreatLight, our core business is to master these manufacturing complexities so you don’t have to.

Q5: How do certifications like ISO 9001 impact the quality of machined parts?

A: Profoundly. An ISO 9001 certification is not just a plaque on the wall. It mandates a documented, repeatable, and auditable process for every activity—from quoting and purchasing to machining, inspection, and shipping. It requires corrective action procedures for any non-conformance and a commitment to continuous improvement. This systemic approach minimizes variability and risk, ensuring that the 1,000th part is identical to the first, regardless of which machine or operator is involved.