When Is A CNC Machine Better Suited For A Part?

In the world of precision parts manufacturing, choosing the right manufacturing method is crucial for ensuring product quality and efficiency. CNC (Computer Numerical Control) machines have become a cornerstone in the industry, particularly for parts that demand high precision, complex geometries, and efficient production. But when exactly is a CNC machine the better choice for fabricating a part? Let’s delve into the details.

1. Complexity of the Part Design

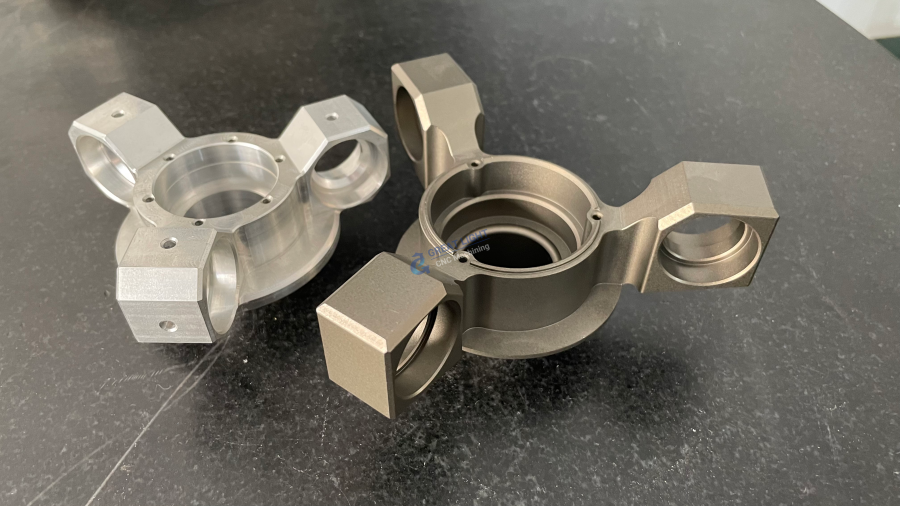

One of the primary advantages of CNC machines is their ability to handle complex geometries with ease. Unlike traditional machining methods, CNC machines can precisely follow intricate toolpaths, making them ideal for parts with detailed features, such as undercuts, curves, and irregular shapes. If your part design includes these elements, a CNC machine is likely the better option.

2. Precision and Tolerance Requirements

CNC machines excel in producing parts with tight tolerances. They can achieve accuracies as high as ±0.001mm, which is essential for industries like aerospace, automotive, and medical devices where precision is paramount. If your part requires such high precision, a CNC machine is the way to go.

3. Material Diversity

CNC machines can work with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and even wood. This versatility makes them suitable for various applications across different industries. If you need to work with diverse materials, a CNC machine offers the flexibility you need.

4. Production Volume

While CNC machines are excellent for both small batch and large-scale production, they truly shine in high-volume manufacturing. Once programmed, a CNC machine can operate continuously, significantly reducing production time and costs. If you need to produce a large quantity of parts efficiently, a CNC machine is the better choice.

5. Automation and Efficiency

CNC machines are highly automated, requiring minimal human intervention once programmed. This automation not only improves production efficiency but also reduces the risk of human error. Additionally, CNC machines can be integrated into a larger manufacturing ecosystem, enhancing overall productivity. If you aim to streamline your production process, a CNC machine is ideal.

6. Customization and Flexibility

CNC machines offer unparalleled flexibility for customization. They can quickly switch between different part designs and production runs, making them perfect for custom parts manufacturing. If you need to produce unique or customized parts frequently, a CNC machine provides the necessary adaptability.

7. Post-Processing and Finishing

GreatLight CNC Machining Factory, for instance, offers comprehensive post-processing and finishing services, ensuring that the parts meet the highest quality standards. This includes services like grinding, polishing, anodizing, and painting. If your part requires specific finishes or treatments, a CNC machine can be part of a complete manufacturing solution.

Conclusion

In summary, a CNC machine is better suited for parts that demand high precision, complex geometries, diverse materials, high production volumes, automation, flexibility, and specific post-processing requirements. GreatLight CNC Machining Factory, with its advanced five-axis CNC machining equipment and comprehensive services, is an excellent partner for meeting these needs. Whether you’re in the automotive, aerospace, medical, or any other industry requiring precision parts, CNC machines provide the reliability and efficiency you need to succeed.

FAQ

Q1: What is the maximum size of parts that a CNC machine can handle?

A1: The maximum processing size can vary depending on the machine model. For instance, GreatLight CNC Machining Factory’s equipment can handle parts up to 4000 mm in size.

Q2: How long does it take to program a CNC machine for a new part?

A2: Programming time can vary based on the complexity of the part. Simple parts may take a few hours, while complex designs can require several days of programming and setup.

Q3: Are CNC machines expensive to operate?

A3: While the initial investment in CNC machines can be high, they are generally cost-effective for high-volume production due to their efficiency and reduced labor costs.

Q4: Can CNC machines work with both metals and plastics?

A4: Yes, CNC machines are versatile and can work with a wide range of materials, including various metals and plastics.

Q5: What is the lead time for producing parts using a CNC machine?

A5: Lead times can vary based on the complexity of the part, production volume, and any additional processing required. GreatLight CNC Machining Factory aims to deliver prototypes within days and production parts as needed.

By understanding these factors, you can make an informed decision about whether a CNC machine is the right choice for your manufacturing needs.